A MapleJet and Funai Collaboration

How new product coding requirements drive the innovation of coding printers

Since time immemorial, product coding is used by manufacturers as a means of keeping track of products and goods throughout the product life cycle. The emergence of product coding began in the 1970s, but it comes with notable challenges. UPC barcodes tend to have limitations and print imperfections that can make coding less efficient and even useless. Today’s 2D codes have a better capacity for tracking and tracing products in the supply chain and in confronting product imitation for manufacturer and customer protection.

Read the complete white paper here…

However, enhanced logistics and counterfeit protection are not the only reasons why manufacturers are transitioning to denser codes. Customers’ behavior which is referred to as “The Participation Economy,” particularly with the millennial generations is one of the driving forces for manufacturers to use denser codes like Quick Readable (QR) codes. This transition to denser codes has also been recognized by GS1.org, the authority in coding, with their release of the plan to call for the end of the UPC code through their “Sunrise 2027.”

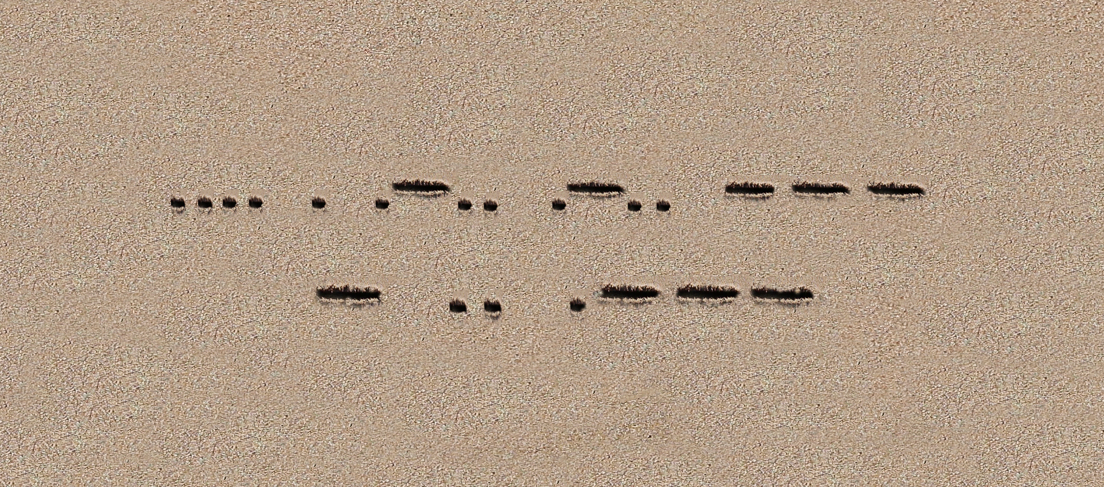

But with this transition to denser codes, will the existing coding and marking technologies be able to keep up? The printing technologies include Continuous Ink Jet, Laser, Thermal Inkjet, and Thermal Transfer Overprint. If different technologies were to be compared, Thermal Inkjet may be the best option to address the shifting coding demands as it has the ability to print machine-readable 2d codes at high speed and high resolution, with the exception of two vital challenges: high cost per mark and throw distance.

This is the reason that MapleJet and Funai have collaborated to understand.

Recent Comments