When summer ramps up, so does production—especially in industries like ice cream, soft drinks, bottled water, and other fast-moving consumer goods (FMCG). These seasonal spikes push production lines to their…

Whether you need to print on a can, bottle, or other beverage packaging, Hx Nitro provides capabilities for all aspects of your beverage line, including glass containers, crowns, foil seals, and aluminium. Click Hx Nitro for specifications and additional information.

The beverage industry has one of the most demanding production line environments. With trends on new packaging designs and materials, coding on bottles and on their secondary packaging needs to be highly efficient and adaptable since manufacturers yearn to catch more consumer attention.

When it comes to printing in the beverage industry, many challenges such as dealing with fast production lines, the need for water-resistant prints, and minimizing the vibration affecting the printers are faced. In this industry, a printer capable of handling fast production lines while maintaining the highest print quality is necessary.

MapleJet’s Hx range of thermal inkjet printers, in combination with next-generation print Funai based-cartridge technology, delivers solvent-based ink with up to 10mm throwing distance at an extremely fast pace, making it the perfect printer for any beverage production line. Providing long-lasting and the finest print quality is MapleJet’s main goal and it is delivered on every product coming out of your production line.

When summer ramps up, so does production—especially in industries like ice cream, soft drinks, bottled water, and other fast-moving consumer goods (FMCG). These seasonal spikes push production lines to their…

As the printing industry evolves, there’s a growing focus on sustainable, eco-friendly solutions that reduce environmental impact without compromising on performance. Water-based inks have emerged as a leading choice for…

Ensuring the safety of our food from farm to fork involves a complex chain of events, from harvesting raw materials to packaging and distribution. At every step, coding and marking…

In North America, the secondary packaging market has seen a lot of growth, driven by the growing demands of industries such as food and beverage, pharmaceuticals, and consumer goods. As…

While plastic packaging is widely used in all industries, the beverage manufacturing industry has adopted plastic packaging the most. 1According to a study made by Statista on the global packaging…

Since its introduction into the coding, marking, and product identification market segment many years ago, thermal inkjet technology has slowly, steadily expanded its market presence. While ink formulations have steadily…

MapleJet’s Hx Nitro thermal inkjet printer excels in beverage manufacturing with high-speed printing, 10mm ink throw distance, and solvent-based inks that deliver long-lasting, water-resistant prints. It’s designed to handle fast production lines while maintaining superior print quality on cans, PET bottles, and glass containers.

Yes! Contrary to common belief, MapleJet’s advanced TIJ technology can print on aluminum cans. Their specialized ink formulations allow reliable, high-quality coding even on challenging metal surfaces like beverage cans, expanding the capabilities of thermal inkjet printing for the beverage industry.

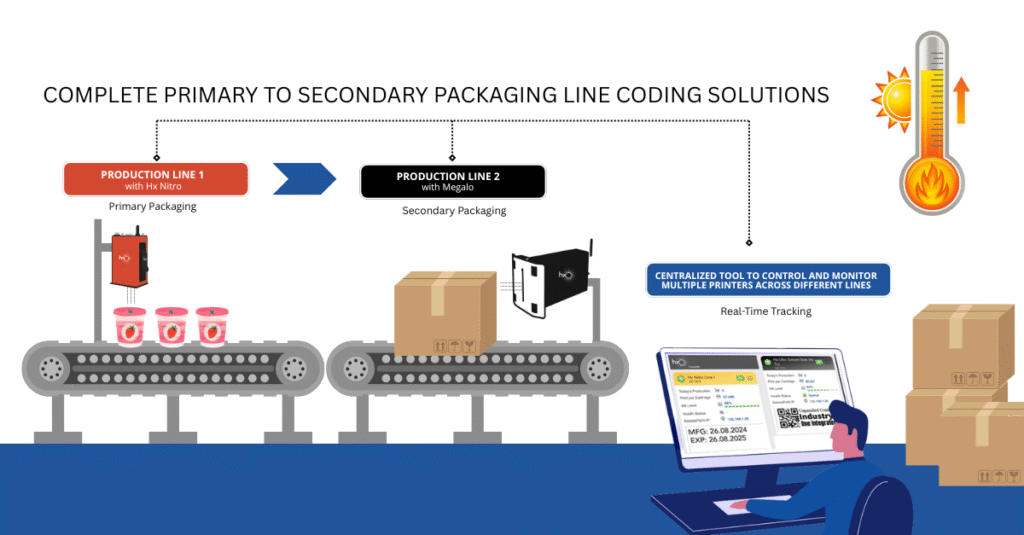

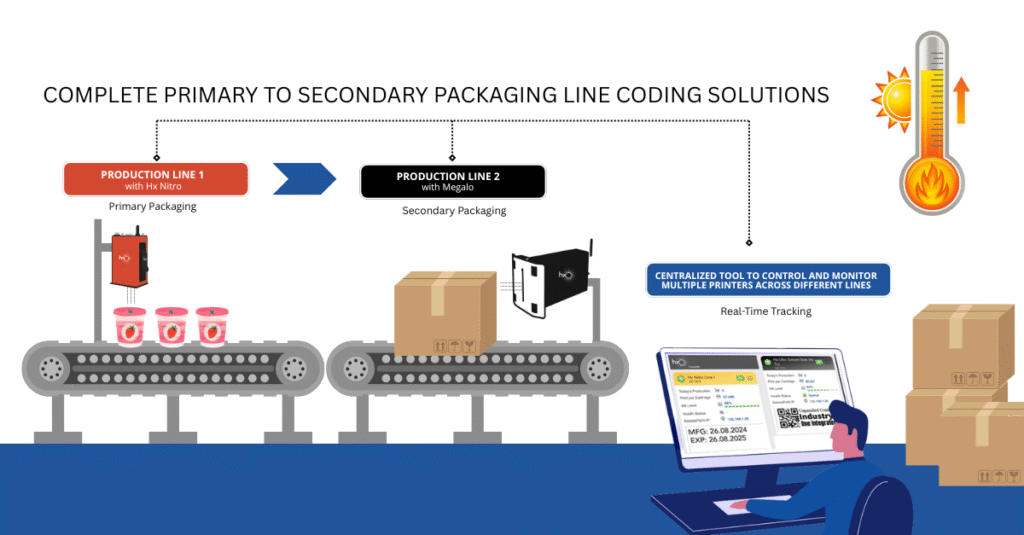

MapleJet printers support a wide range of beverage packaging, including PET bottles, glass bottles, carton boxes, and cans. Whether it’s primary packaging like bottles or secondary packaging like boxes and trays, MapleJet ensures precise, durable coding for all stages of beverage production.

MapleJet’s printers use Funai-based cartridge technology, offering fast-drying solvent inks and advanced print control. This ensures sharp, consistent prints even at high speeds, overcoming vibrations and maintaining code integrity essential in high-output beverage manufacturing environments.

Absolutely. MapleJet’s coding solutions, especially the Hx Nitro range, are built to handle increased demand during peak seasons like summer, when beverage production ramps up. They maintain high-speed, high-quality printing, minimizing downtime during busy production cycles.

Yes. MapleJet supports sustainable practices with water-based inks, which offer eco-friendly, low-VOC printing without compromising print quality. These inks meet growing industry demands for environmentally responsible solutions while delivering reliable codes on beverage packaging.

MapleJet’s secondary packaging solutions, like the Hx Cartro and Hx Megalo, provide reliable, high-resolution printing on cartons, corrugated boxes, and trays. This ensures clear, legible codes that meet regulatory and supply chain needs for traceability and product identification across large volumes.

Founded in 2007 in Toronto, Canada, MapleJet has over 18 years of experience providing innovative, cost-effective coding and marking solutions worldwide. Their philosophy combines quality, simplicity, and low total cost of ownership, making them a trusted partner in industrial printing.

MapleJet printers tackle key challenges like high-speed production, water-resistant coding, and vibration-related issues on lines. Their Hx printers ensure consistent, high-quality codes on diverse packaging, helping beverage manufacturers maintain compliance and product integrity.

MapleJet provides comprehensive resources, including Hx Nitro and Hx Cartro training videos, industry application demos, and technical support through their website. These resources help operators install, operate, and maintain printers efficiently, ensuring smooth production and minimal downtime.