Description

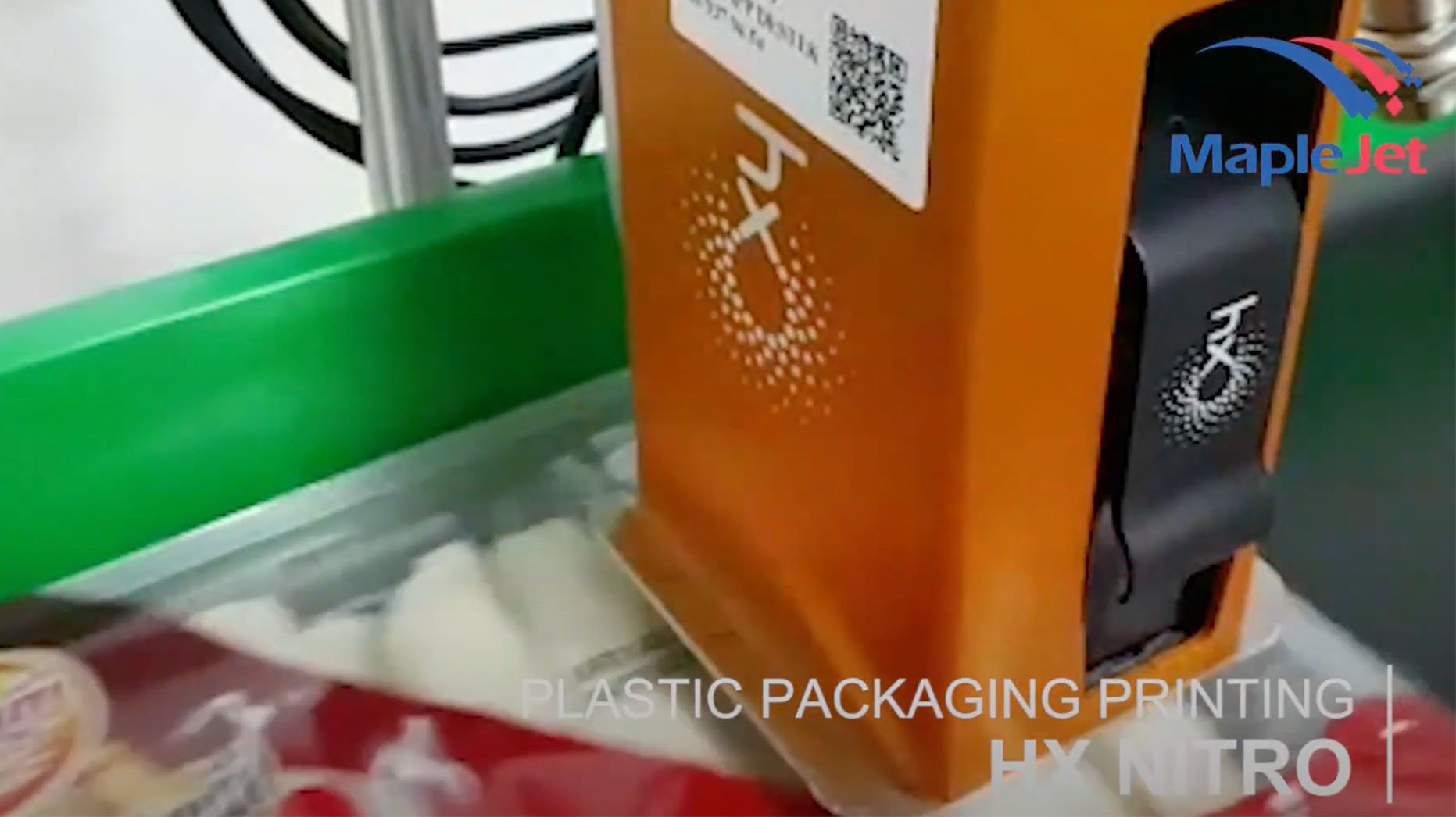

Hx Nitro Box coder works perfectly with fast-drying high-throw distance solvent-based ink. Its integrated printhead removes the hassles of bulky and coding & marking. All by reducing your overall production cost. The printer is suitable for high-speed and high-volume production lines.

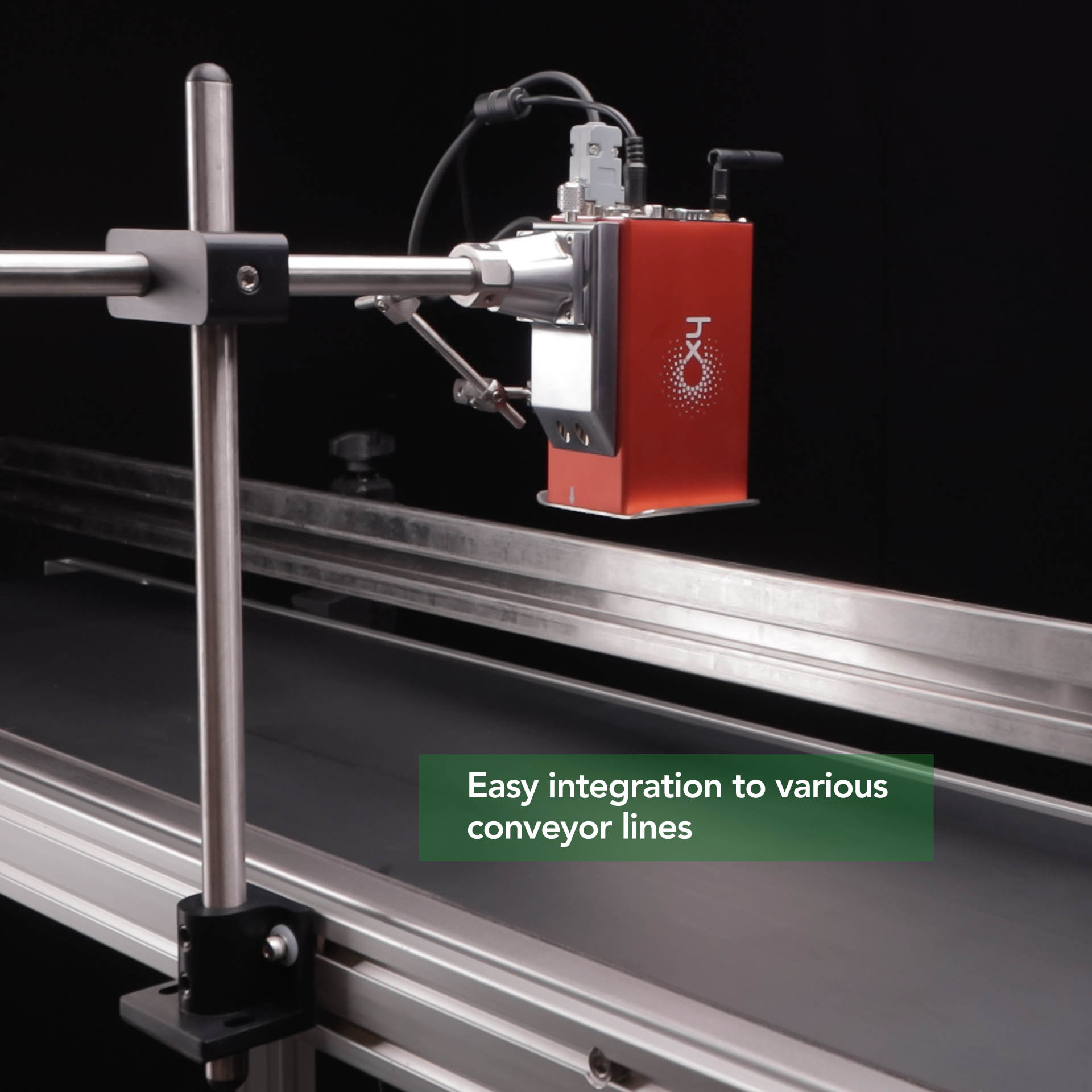

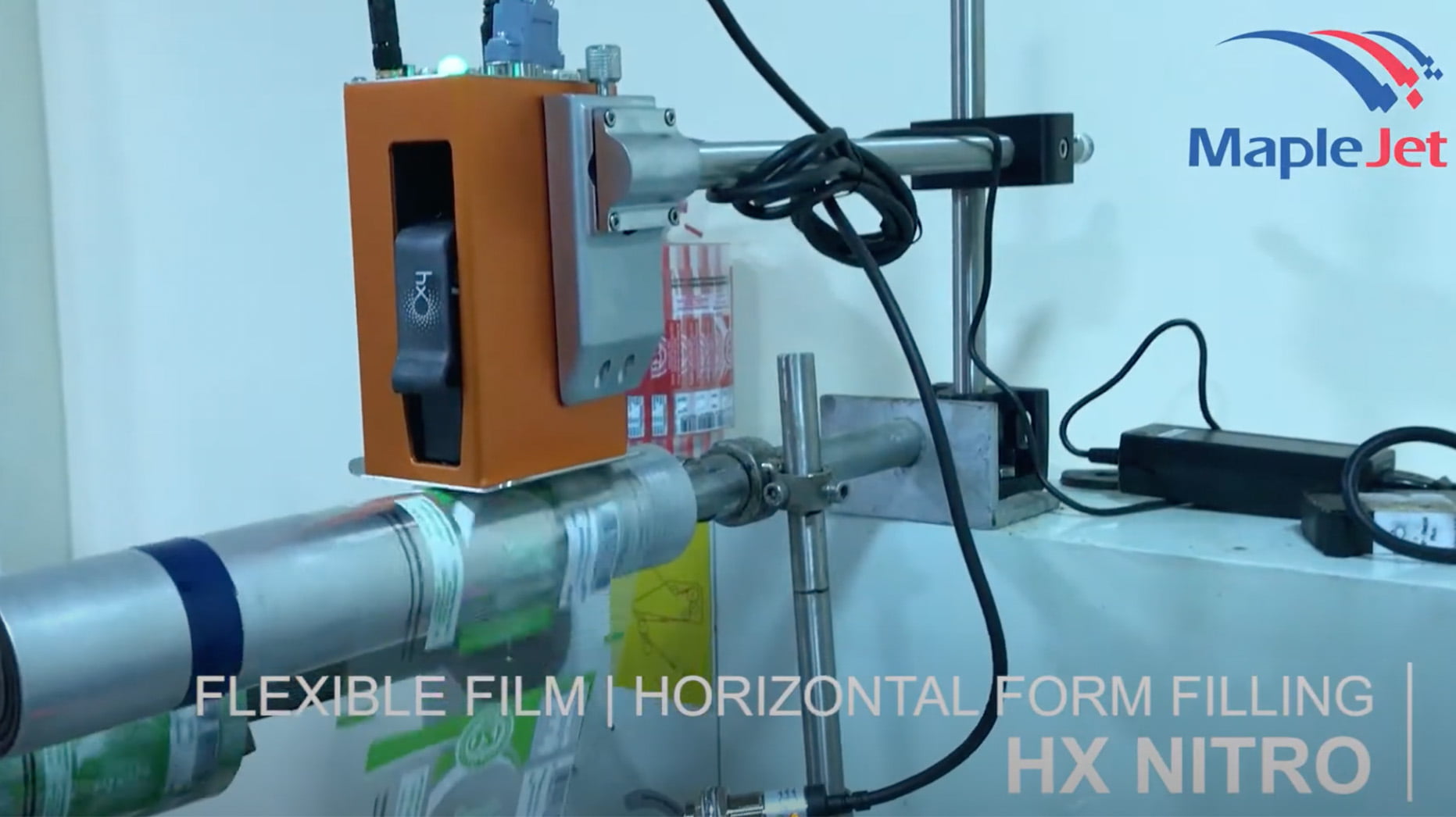

Versatility and Flexibility

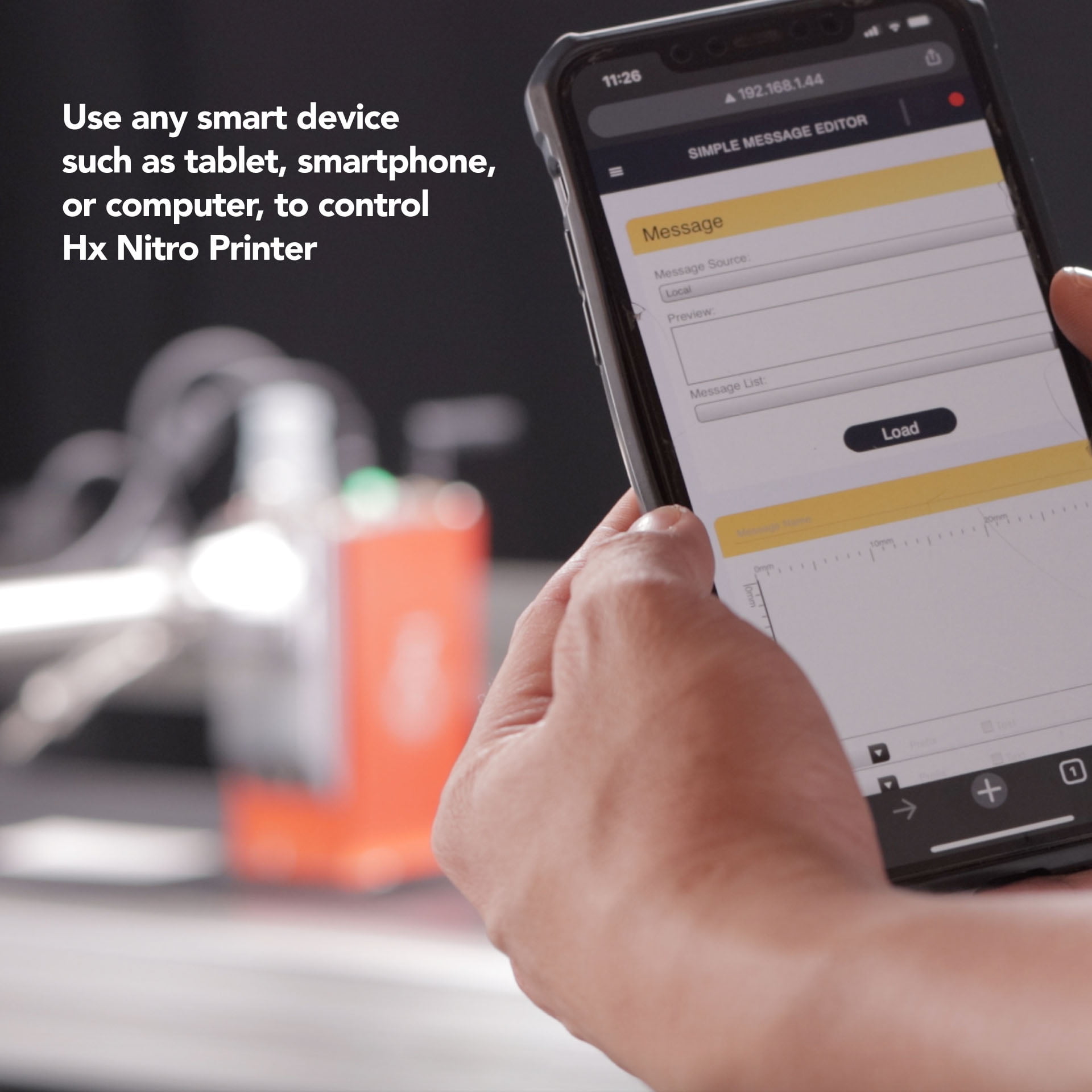

Hx Nitro Box coder works with mobile or smartphones and any Windows-based computer and tablet devices. Flexible and easy to install in various production lines such as simple conveyor lines, horizontal form filling, and vertical form filling lines.

Simple & Easy Operation

Hx Nitro TIJ printing can work using your smartphone or any smart device via direct Wi-Fi (no need for an Internet Connection) or Access Point. You can design a 4-line message or monitor your production line with these smart devices. No need for a hard-touch controller pad.

Small Footprint Design

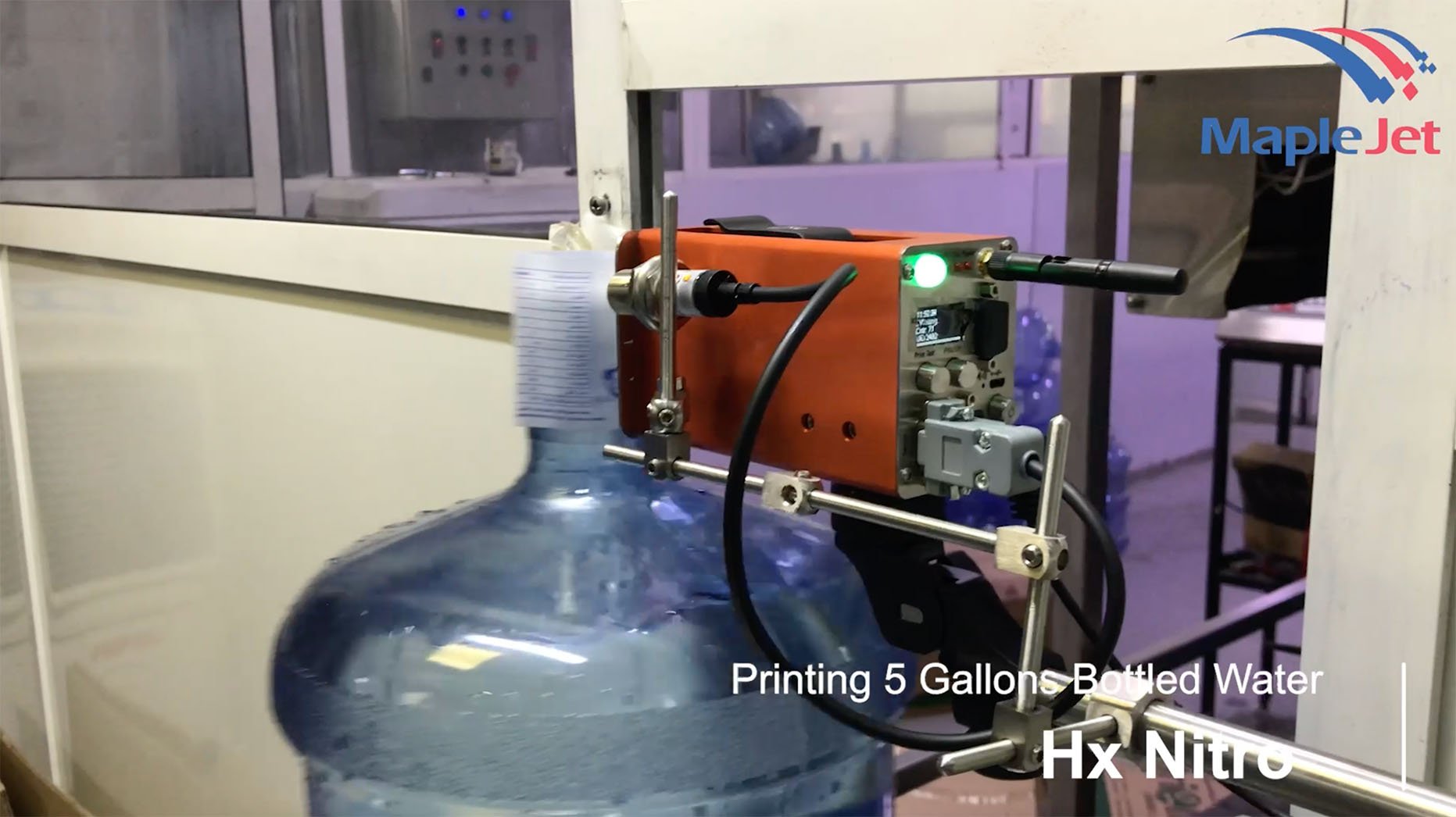

The actual controller weighs 750gm with 146mm x 84mm x 60mm dimensions making Hx Nitro Box coder on the beverage production line one of the lightest industrial TIJ printers. Thus, it can be installed on any part of the packaging machine that best provides the perfect coding experience for your production line.

Connection and Communication

- Connect directly via Hx Nitro printer’s built-in Wi-Fi module using a direct IP Address. No need for an Internet Connection.

- Connect via Access Point or Company Wi-Fi. This connection provides more printer functionalities such as Printer Health Check, Ink Consumption Calculator, Field Upgrade, and more! Also, you can connect to multiple printers in your production line using one smart device.

- Connect via USB port

Ink Compatibility

Hx Nitro Box coder on the food production line is compatible with MapleJet Porous and Non-porous ink types. Depending on your packaging materials you can select from the following ink types;

- Boxtron (Black, Blue, and Red) – perfect for printing onto corrugated boxes, cartons and paperboards.

- Chronplast-S – fast-drying ink that works perfectly with Metal, PET, PE, and Glossy or coated paper. Recommended on the high-temperature working environment.

- Chronplast-W – fast-drying ink perfect for any porous and non-porous substrate. Recommended in the low-temperature working environment.

- eUrex_HT – a high-throw distance cartridge ideal for PVC, PP, PET, ABS, Metal, Glass, Polystyrene and Treated Polyethylene film.

- Ultraflex –super-fast drying ink perfect for non-porous substrates such as BOPP, HDPE, PE, PP, PVC, PET, ABS, Polystyrene, and Treated Polyethylene film.

Almost Maintenance-free and No Service Contracts

- Get the latest version of the printer remotely with Field Upgrade Function. No need for Field Engineer visit to upgrade your printer to its latest version & NO EXTRA PAYMENT required

- Hx Nitro Box coding machine is maintenance-free. No need for regular Field Engineer Visit or outsourced maintenance

- No service contract.

- No regular expensive parts replacement

- Replacing the cartridge makes the printer good as new

- Self-maintenance is available when needed.

Training Videos and a Quick User Guide are Available Online

Catalogue

Featured Videos of Hx Nitro Box coder on Food Production Lines

Featured Videos of Hx Nitro Box coder on Beverage Production Lines

Featured Blogs

Tray sealers and thermoformers used in food packaging require a high-performance coding solution that ensures compliance, traceability, and clear legibility across flexible and rigid packaging substrates. Small and medium-sized enterprises…

Small to medium enterprises using label applicators often rely on pre-printed labels to include product details, batch numbers, and expiry dates. But as product variations increase and compliance demands shift,…

In offline roll-to-roll (R2R) printing applications, especially common in small to medium-sized enterprises (SMEs), efficiency, flexibility, and simplicity are crucial. These setups typically involve printing variable data—like batch numbers, expiry…