Bottle Coders

All Bottle Coder Printers

-

Maplejet Hx Nitro 25w One-Inch Thermal Inkjet Printer

From: US$1,500Select options This product has multiple variants. The options may be chosen on the product page Quick View

Bottle Coding Printer

MapleJet specializes in advanced bottle coding printers, offering solutions that deliver precision and efficiency for a wide range of industries. Our bottle coders are engineered to produce clear, permanent markings on various materials, including glass, plastic, and metal, ensuring reliability in every production cycle. Designed for industries, such as beverages, pharmaceuticals, and cosmetics, our bottle coding technology supports high-speed operations while maintaining impeccable print quality.

Bottle coding and marking present unique challenges due to the varied shapes and surfaces of bottles, particularly on curves and shoulders where traditional technologies may struggle. While several technologies can print on bottles, the advent of high-throw distance printheads in thermal inkjet printers represents a significant advancement. These printheads, like those found in the MapleJet Hx printer, overcome the limitations of older systems by effectively printing on difficult-to-reach areas such as bottle shoulders, providing greater flexibility and accuracy in coding.

The MapleJet Bottle Coder stands out as an ideal solution for these challenges due to its high-resolution printing capabilities and advanced printhead technology. It delivers clear, durable markings on various bottle surfaces and materials, including the challenging bottle shoulder area. Its compact design and easy integration into production lines, combined with fast-drying inks, ensure legible and resistant codes, making it a practical and efficient choice for modern bottle coding needs.

Each machine features user-friendly controls, robust hardware, and flexible configurations to adapt seamlessly to your production line. By integrating MapleJet’s innovative bottle coding solutions, manufacturers can achieve compliance with regulatory standards, enhance product traceability, and improve operational efficiency. Lean on MapleJet for dependable, high-performance bottle coding systems tailored to meet the unique demands of your business.

- Description

- Advanced Features

- Ink Compatibility

- Gallery

- Catalogue

Maplejet’s Bottle coder are compact and durable devices that use heat to transfer ink onto a label or directly onto a bottle. They are known for their speed, accuracy, and versatility, making them a popular choice for printing date codes. These printers can print a wide range of symbols, numbers, and letters, making them ideal for bottle coding.

When it comes to printing date codes onto bottles, the type of ink used is important. Maplejet Bottle coding printer typically use thermal transfer ink which is waterproof, smudge-proof, and heat-resistant. This makes it ideal for use on bottles as it can withstand various environmental conditions that the bottles may be exposed to.

30-Day Performance Guarantee

Every MapleJet Bottle Coder comes with our 30-Day Performance Guarantee. If it doesn’t meet your expectations, you can return it hassle-free. Our printers are designed for easy self-installation and maintenance, but we also provide a library of installation videos on our website. Need more personalized support? Schedule an appointment with one of MapleJet’s experts. Our innovative solutions designed to streamline your coding and marking processes. #CodingAndMarkingMadeEasy.

Do you need help choosing the right Bottle Coder?

Our team of experts is ready to assist you in selecting the perfect bottle coder tailored to meet your specific operational needs. Request a free quote to book an equipment consultation today!

| Feature | Description |

|---|---|

| AUTO NOTIFY | Allows other external devices to control and monitor Hx Printer. Any third-party device (e.g., PLC), system, or software can send a command to Hx Printer. |

| AUTO PILOT | Events such as ‘low ink level’, ‘printing completed’, and ‘online data received’ can be automatically communicated by choosing selected channels e.g. USB, RS232, and Wi-Fi (HTTP). |

| FIELD UPGRADE | Allows the printer’s software to be upgraded remotely. |

| INK ESTIMATION CALCULATOR | Provides an estimate number of prints per cartridge based on the message and other parameters. |

| EXTERNAL DATA | Easy integration to external devices e.g., PLC, weighing scale, etc., for printing variable data. Auto calculation and printing of the product weight. Allows other external devices to control and monitor Hx Printer. Any third-party device (e.g., PLC), system, or software can send a command to Hx Printer. |

| ECONOMY MODE | Reduces ink consumption to up to 50% increasing print quantity. |

| PRINTER HEALTH CHECK | Detects warnings to avoid future or unwanted downtime. |

| ROLLOVER TIME | Easily customise time and date as per the company’s required production time or work shift. |

High-Performance Inks for All Materials:

Fast Drying, Leak-Free, Low VOC

-

Sale!

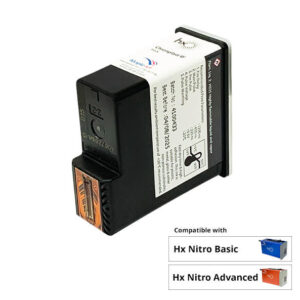

Hx Nitro UltraFlex Ink Cartridge

From: US$115Select options This product has multiple variants. The options may be chosen on the product page Quick View -

Sale!

Hx Nitro eUrex High-Throw Ink Cartridge

From: US$125Select options This product has multiple variants. The options may be chosen on the product page Quick View -

Sale!

Hx Nitro ChronPlast-W Ink Cartridge

From: US$105Select options This product has multiple variants. The options may be chosen on the product page Quick View -

Sale!

Hx Nitro ChronPlast-S Ink Cartridge

From: US$105Select options This product has multiple variants. The options may be chosen on the product page Quick View -

Sale!

Hx Nitro Boxtron Ink Cartridge

From: US$75Select options This product has multiple variants. The options may be chosen on the product page Quick View

TALK TO AN EXPERT

What Our Customers Say About Us!

- Home

- Shop

- Products

- Industries

- Applications

- Resources

- About Us

- Contact Us

Founded in 2007 in Toronto, Canada, MapleJet’s Business philosophy is based on finding the perfect balance between quality, simplicity and low cost of ownership.

Head Office

4 Vata Court, Unit 20

Ontario, L4G 4B6, Canada

T: (833) 387-7490