Flexible packaging lines demand high-performance coding solutions that can keep up with speed, maintain adhesion on non-porous materials, and minimize running costs. In production lines such as roll-to-roll (winder-rewinder), Horizontal Form Fill Seal (HFFS), and vertical Form Fill Seal (VFFS), having the right printer can streamline your operation and reduce downtime.

This is where the Hx Ultro Bulk Ink Thermal Inkjet (TIJ) printer stands out. Designed specifically for flexible packaging, Hx Ultro combines exceptional print quality, operational efficiency, and smart integration features. It’s an ideal bulk ink printer for flexible packaging, outperforming traditional CIJ printers in key production areas.

Hx Ultro Bulk Ink TIJ – Built for Flexible Packaging Efficiency

For laminated films, pouches, and pre-printed rolls, the Hx Ultro Bulk Ink TIJ delivers production-ready advantages:

- Sharp, High-Resolution Codes:

Ensures barcode accuracy and traceability, reducing rework and compliance issues. - Fast-Drying, High-Adhesion Inks:

Prints instantly on non-porous flexible substrates—no smudging, crisp print quality, less waste, and fewer delays. - Bulk Ink Cartridge by Funai:

Aggressive-ink-compatible, built for long runs with minimal changeovers, lowering the cost-per-print. - Flexible Print Orientation:

Rotate print direction to match pre-printed artwork—ideal for roll-fed packaging and easy line integration. - Low Maintenance, Lower Operating Costs:

No make-up fluids, fewer service interruptions—saves time, reduces consumables, and cuts total cost of ownership.

Print Orientation Advantage – Matching the Direction of Pre-Printed Packaging

A common challenge in flexible packaging is aligning the print direction with pre-printed graphics or label formats. With CIJ printers, this often requires awkward adjustments or special mounting.

Hx Ultro TIJ solves this with its built-in print rotation feature, allowing you to match the code’s direction exactly with the artwork on the roll or pouch, ensuring professional, clean output every time.

This print flexibility is a major advantage for purchasing and production managers seeking both integration ease and packaging consistency.

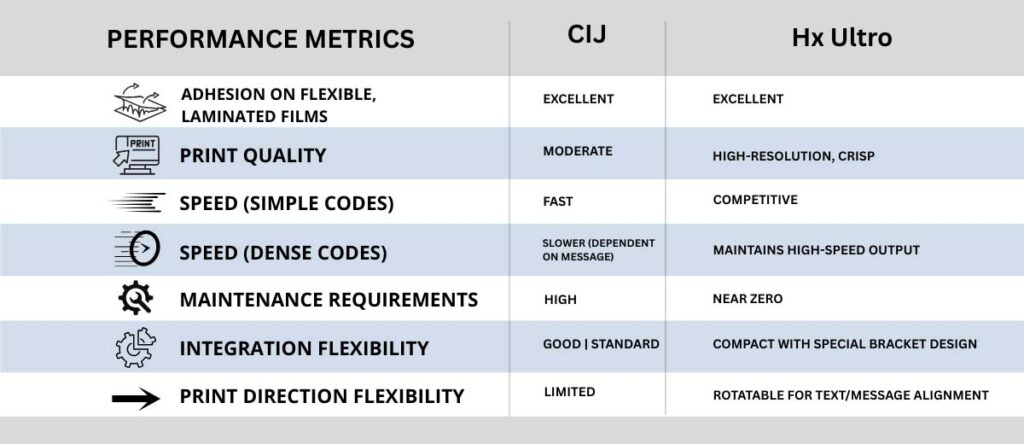

CIJ vs. Hx Ultro: Which Is Better for Flexible Packaging?

CIJ printers use MEK-based inks and make-up fluid to achieve good adhesion on non-porous surfaces. However, they are high-maintenance, costly to operate, and produce moderate-quality codes.

By contrast, Hx Ultro offers:

- Cleaner operation with cartridge-based ink delivery

- Sharper print quality, even with dense barcodes and serialized data

- Minimal maintenance due to TIJ architecture

- High adhesion coding on glossy and laminated films

- Competitive speed even at high data density

At a Glance: CIJ vs. Hx Ultro

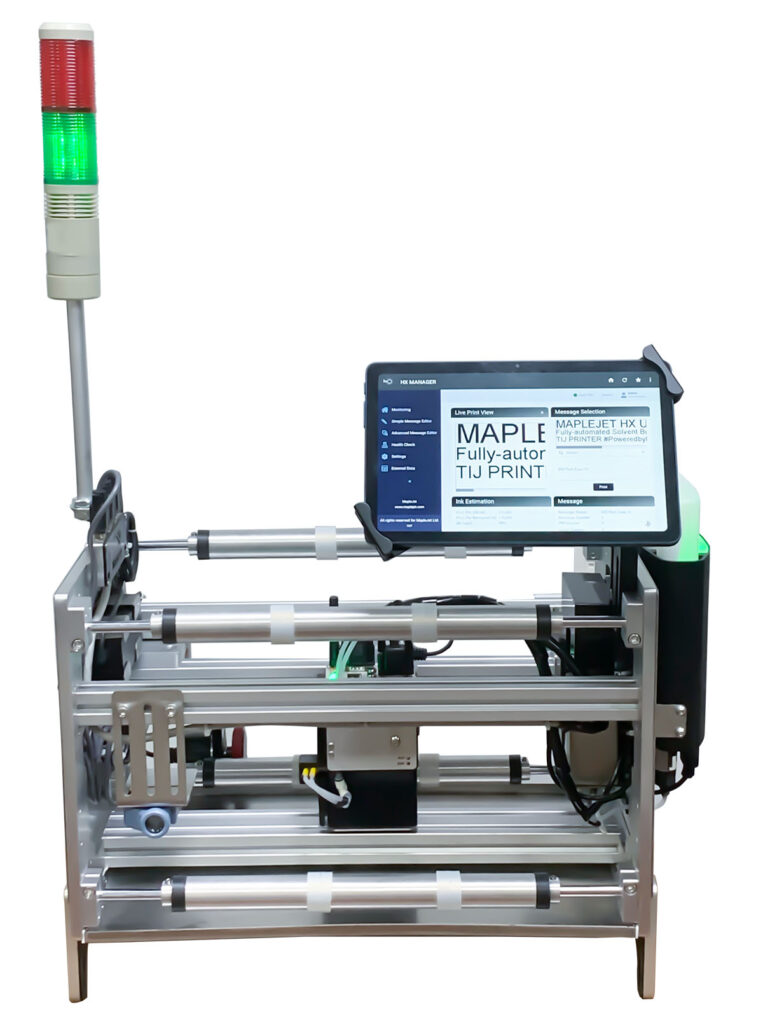

Specialized Solution – Hx Ultro CodeMax for HFFS and VFFS

While Hx Ultro Bulk Ink TIJ is the go-to solution for any flexible packaging applications such as roll-to-roll and high-volume lines, the Hx Ultro CodeMax is especially designed for VFFS and HFFS applications.

Its advantages include:

Compact build and new specialized bracket designed for seamless integration and operations in vertical and horizontal form-fill-seal setups

Aggressive solvent ink compatibility with Funai’s cartridge technology for better print quality and long-lasting operation

Clean operation, high print quality, and reliable performance with minimal maintenance

It’s the perfect solution when space is tight, speed is variable, and precision is non-negotiable.

A Smarter Coding Machine for Laminated Film

The Hx Ultro is specifically designed to meet the demands of laminated, non-porous packaging materials. Its fast-drying ink bonds quickly and securely to flexible substrates—eliminating smudging and ensuring consistent barcode readability, even at high speeds.

Whether you’re printing date codes, batch numbers, QR codes, or serialized data, Hx Ultro delivers industrial-grade performance with TIJ simplicity.

Smarter Control with Hx Console and MapleJet Cloud

To meet today’s flexible packaging demands, software matters just as much as hardware. That’s why MapleJet pairs its industrial printers with smart software solutions that directly support both quality control and production efficiency.

- Hx Console – Centralized Control for Quality Assurance

Hx Console enables a single Human-Machine Interface (HMI) to control multiple printers on the same production line. This centralized setup helps Quality Control Managers ensure uniform print quality, enforce standardized code formats, and reduce the risk of manual errors across multiple packaging lines. It simplifies oversight, saves operator time, and ensures consistency across SKUs, shifts, and product batches—all from one intuitive interface.

- MapleJet Cloud – Data-Driven Production Intelligence

MapleJet Cloud gives Production Managers real-time visibility into printer status, job progress, ink levels, and performance metrics across all lines. More than just monitoring, it provides actionable insights: - Identify peak production hours to optimize shift schedules

- Use historical data to plan raw material space and reduce floor congestion

- Make proactive decisions to reduce downtime and keep throughput high

With cloud access from anywhere, it’s an indispensable tool for scaling operations intelligently.

Why Switch to Hx Ultro Bulk Ink TIJ Printer in Flexible Packaging?

✅ Uses aggressive ink-compatible bulk cartridge technology by Funai — reliable performance with solvent inks designed for non-porous packaging

✅ Thermal inkjet for flexible packaging that rivals CIJ adhesion without the complexity

✅ Bulk ink printer offering significantly lower maintenance and operating costs

✅ Equipped with a specialized mounting bracket for precise installation and consistent high-speed printing

✅ Centralized print management with Hx Console — control and monitor multiple printers from one HMI.

Looking to upgrade your flexible packaging coding system?

The Hx Ultro & Hx Ultro CodeMax offer a clean, efficient, and scalable alternative to CIJ—designed to meet the needs of modern flexible packaging production.

Recent Comments