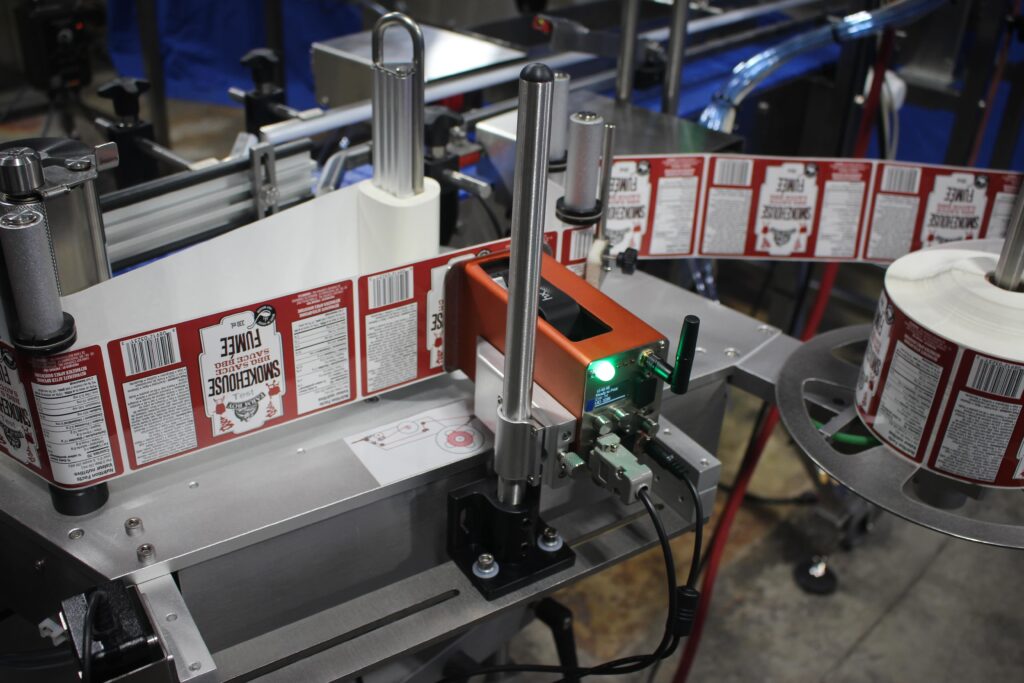

If you’re running label applicators, you’ve probably dealt with it. Clogged nozzles. Faded prints. Unreadable barcodes. Downtime. Although it’s the final stage of the production cycle it doesn’t diminish it’s importance. Printing variable data like expiry dates, batch codes, and barcodes, should be the easy part. However for many businesses, it’s the source of repeated frustration.

Whether you’re running a packaging line for food, cosmetics, or consumer goods, the last thing you need is downtime due to messy, inconsistent printers.

At MapleJet, we’ve engineered a smarter solution.

The Problem with Traditional Printing Solutions

CIJ (Continuous Inkjet) printers have long been a default choice for label printing. But behind the scenes, they bring:

- High operational costs

- Frequent maintenance requirements

- Messy ink and solvent handling

- Costly production delays

On the other side, many thermal inkjet (TIJ) printers using traditional outdated cartridges introduce new problems:

- Ink drying and nozzle clogging

- Poor adhesion on glossy or coated label materials

- Inconsistent print quality under variable speeds

These problems lead to misprints, wasted labels, and production stoppages, which ultimately cost time and money.

The MapleJet Solution: Smart, Clean, and Reliable TIJ Printing

At MapleJet, we’ve engineered a family of TIJ printers designed specifically to work seamlessly with label applicator systems and to eliminate the pain points you’ve been forced to live with.

🔹 Compact Design

Our printers are small, lightweight, and easy to integrate into tight production environments—giving operators more space to work and eliminating obstacles around conveyor belts and applicators.

💰 Cut Costs vs CIJ

Compared to CIJ printers, MapleJet TIJ systems offer:

- No hazardous solvents like MEK

- No special storage needs

- No maintenance routines

- No solvents or messy fluids

- No downtime from printhead cleaning

- Better for your team and the environment

💡 Say Goodbye to Clogging and Adhesion Issues

Our Chronplast-W ink is designed for label materials. It offers:

- Exceptional adhesion on coated and glossy substrates

- No clogging or drying, even during long production pauses

- Consistent, high-resolution printing, batch after batch

The result? A drastically lower total cost of ownership, without sacrificing print quality.

Smarter Printing with Industry 4.0 Integration

Our TIJ printers aren’t just drop-in replacements. They’re designed for the future of packaging.

Here’s what makes them Industry 4.0-ready:

- IP-Based Control System (Hx Manager): Control your printer directly from any smart device.

- PLC Integration: Seamlessly connect to automation systems, or direct data, no middleware required.

- Hx Console: Centrally monitor and manage all MapleJet printers on your production line from a single interface.

- Hx Cloud: Access real-time data feedback, receive alerts, and control your printer from anywhere in the world.

These tools give production teams centralized visibility, allowing them to spot errors instantly, adjust printer settings remotely, and optimize efficiency across multiple lines. Whether you’re managing one printer and facility or several, MapleJet helps you stay in control.

Which Printer Fits Your Line?

Our TIJ lineup offers flexibility depending on your label applicator configuration and printing needs:

| Printer | Print Height | Ink Type |

|---|---|---|

| Hx Nitro | 0.5 inch (12.7mm) | Cartridge (Non-Porous Material) |

| Hx Nitro 25w | 1 inch (25mm) | Cartridge (Porous Material) |

| Hx Ultro | 0.5 inch (12.7mm) | Bulk Ink (Non-Porous Material) |

| Hx Ultro 25w | 1 inch (25mm) | Bulk Ink (Porous Material) |

Each model can be easily integrated into label applicator machines, no need for any hardware adjustments.

Built for Real-World Challenges

We’ve seen it firsthand: manufacturers constantly fighting with clogged printheads, rejected batches, and expensive repairs. Our TIJ printers are built to fix those frustrations and deliver flawless performance.

Whether you’re switching from CIJ, upgrading from another TIJ, or building a new labeling line from scratch, MapleJet gives you:

- ✅ Clean operation

- ✅ Lower costs

- ✅ Smarter integration

- ✅ Consistent print quality

- ✅ Simple setup and remote control

Ready to Upgrade Your Label Applicator?

Join the growing number of manufacturers choosing MapleJet for their label printing needs.

Recent Comments