When summer ramps up, so does production, especially in industries like ice cream, soft drinks, bottled water, and other fast-moving consumer goods (FMCG). These seasonal spikes push production lines to their limits, where even minor downtime or coding errors can have costly consequences.

To meet the challenge, manufacturers need more than just reliable hardware. They need smart coding solutions designed to handle fast-paced output, dynamic changeovers, and seamless integration—all without sacrificing accuracy or compliance.

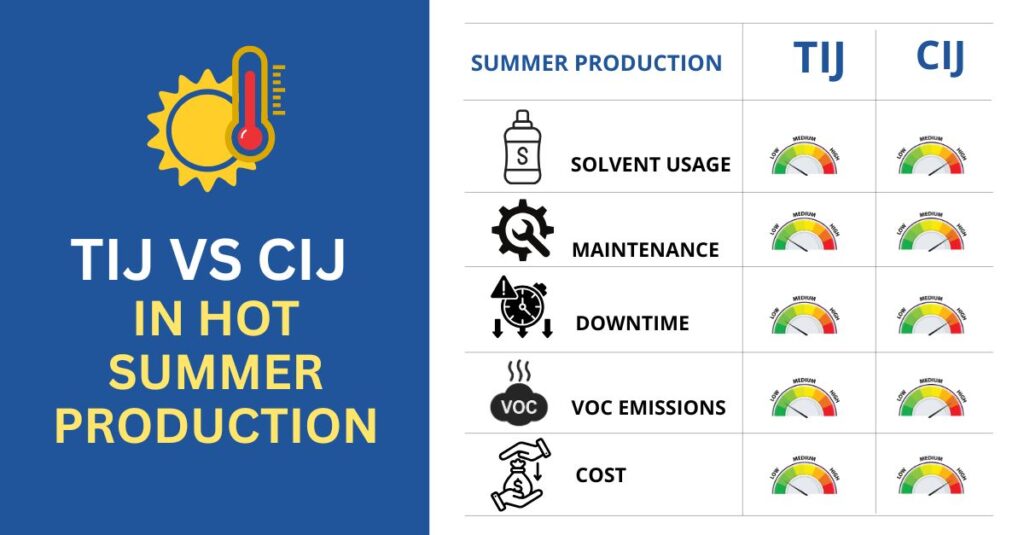

For manufacturers relying on traditional CIJ printers, the heat brings additional challenges: increased solvent evaporation, more frequent refilling, and rising consumable costs. In contrast, smart coding solutions like MapleJet’s thermal inkjet printers offer clean, efficient, and maintenance-free operation—making them ideal for summer-intensive production environments.

That’s where MapleJet delivers. Our advanced thermal inkjet printer for FMCG and industrial inkjet printer for food packaging are engineered for speed, precision, and smart connectivity—making them the ideal choice for summer-focused manufacturing lines.

End-to-End Coding for Primary & Secondary Packaging

Seasonal industries often deal with both primary and secondary packaging, each requiring specific printing capabilities. MapleJet offers a complete portfolio of printers to cover every stage of your packaging process:

Primary Packaging Solutions

Ideal for coding directly on flexible film, sachets, bottles, and pouches.

- Hx Nitro TIJ – Compact, user-friendly, perfect for small manufacturing lines

- Hx Ultro Bulk Ink TIJ – High-volume thermal inkjet printer with bulk ink system for long runs and cost efficiency

Secondary Packaging Solutions

Best for corrugated boxes and outer cartons.

- Hx Nitro 25w (25mm) – Water-based thermal inkjet, single-head up to 25mm, excellent for medium-speed box coding

- Hx Ultro 25w Bulk Ink TIJ – Bulk ink version of 25mm TIJ for high-speed, high-volume secondary lines

- Hx Cartro (36mm) – Oil-based large character printer with biobased ink option, built for sustainability

- Hx Megalo (70mm) – Large character printer for larger prints, bold barcodes, and large logos on shipping cartons

This full range of industrial inkjet solutions ensures complete flexibility across your packaging workflow—especially important when handling short runs, multi-language SKUs, or private label products common in summer promotions.

Summer Production Demands: What’s at Stake?

Seasonal manufacturers face unique challenges such as:

- High-speed production lines where reliability is non-negotiable

- Diverse packaging formats, including PET bottles, plastic wraps, and cartons

- Frequent product and batch changes, requiring agile print management

- Regulatory and traceability coding, including expiry dates and batch numbers

- The pressure to maintain uptime during seasonal peaks

With these complexities, the need for smarter, faster, and more adaptable coding technologies is more urgent than ever.

MapleJet’s Smart Coding Solutions: What Makes the Difference?

MapleJet’s Hx series of thermal inkjet printers for FMCG are backed by MapleJet Cloud to form a complete smart coding solution—helping brands meet their summer production goals while preparing for future requirements like GS1 Sunrise 2027.

✅ Speed + Resolution

The Hx series delivers high-resolution codes at rapid speeds without slowing down your production line—ideal for coding ice cream containers, bottled beverages, snack packaging, and more.

✅ Compact, Flexible Installation

Designed industrial and compact, these printers easily fit into tight spaces like form-fill-seal machines or bottling lines, making them perfect for expanding seasonal lines without overhauling the setup.

✅ Cloud-Based Print Management

The MapleJet Cloud platform transforms your coding process by enabling:

- Printer monitoring from any smart device

- Real-time performance analytics and error alerts

These cloud-powered smart coding solutions reduce downtime, coding errors, and operator intervention—critical advantages during high-volume summer runs.

Why Thermal Inkjet Outperforms CIJ in Hot Production Environments

Continuous Inkjet (CIJ) printers are widely used in many production lines, but during summer, their solvent consumption increases significantly. As ambient temperatures rise, so does solvent evaporation, leading to:

- Higher usage of make-up fluids

- More frequent top-ups and shutdowns

- Increased VOC emissions and unpleasant odors

- Greater burden on maintenance staff

This not only impacts running costs but also disrupts production—especially in hot regions where factory floors aren’t climate-controlled.

MapleJet’s thermal inkjet (TIJ) printers, including the Hx Nitro and Hx Ultro series, don’t use make-up fluids. They operate with clean cartridges, require zero maintenance for ink management, and provide consistent performance even in high-heat conditions. This makes them an ideal alternative to CIJ systems for seasonal industries ramping up during summer months.

Preparing for GS1 Sunrise 2027

The global push toward GS1-compliant 2D codes—especially under the Sunrise 2027 initiative—is reshaping packaging compliance. These new codes will carry not just product IDs, but batch numbers, expiry dates, and traceability info in a single scan.

MapleJet’s industrial inkjet printers for food packaging are ready for this shift, offering high-resolution printing for GS1 Digital Link, Data Matrix, and 2D barcodes—all with the speed and clarity demanded by high-throughput summer operations.

Engage Consumers with Smart QR Codes

Summer isn’t just about production—it’s also a key moment for marketing campaigns. From contests to limited-time promotions, brands can print dynamic QR codes directly on product packaging to:

- Direct customers to campaign microsites

- Track consumer engagement and location data

- Share sustainability stories or behind-the-scenes content

- Drive repeat purchases via loyalty programs

While the QR codes themselves can create unique consumer touchpoints, MapleJet Cloud plays a different but equally critical role. It provides production teams and plant managers with real-time insights into line performance.

By offering a data-driven view of what’s happening on the factory floor, MapleJet Cloud empowers teams to make better decisions on staffing, maintenance, and material planning—especially during high-demand summer months.

Final Thoughts

Summer production demands speed, agility, and reliability. With MapleJet’s thermal inkjet printer for FMCG applications and our cloud-based smart coding solutions, manufacturers get a future-proof edge—ready for today’s challenges and tomorrow’s standards.

Whether you’re coding soft drinks, frozen snacks, or launching summer promos via QR codes, trust MapleJet to deliver smart, fast, and reliable printing—from primary to secondary packaging.

Let’s get your production line ready for summer.

Contact us today to explore the most flexible and compliant industrial inkjet printer for food packaging and start building a smarter coding strategy with MapleJet Cloud.

Recent Comments