In North America, the secondary packaging market has seen a lot of growth, driven by the growing demands of industries such as food and beverage, pharmaceuticals, and consumer goods. As businesses strive to meet these growing demands, efficient and traceable coding secondary packaging coding solutions have become more crucial. MapleJet leads the way, offering solutions that not only ensure compliance with regulatory standards but also enhance supply chain visibility and product authenticity.

Challenges in Secondary Packaging Coding

High Volume Production Challenges: Large companies often face challenges managing high-volume production lines as it can be daunting. The primary challenges include Ensuring consistent print quality, integrating coding solutions seamlessly into high-speed manufacturing lines, and minimizing downtime can be difficult. Additionally, the complexity increases when handling large amounts of data for traceability and compliance with evolving global regulations.

Small-Medium Volume Production Challenges: Small to medium enterprises (SMEs) face different hurdles, primarily around cost and scalability. These companies need secondary packaging coding solutions that are cost-effective, easy to integrate, and flexible. SMEs also require systems that can be easily adjusted or upgraded as their production needs change and grow.

MapleJet’s Hx Cartro: A Bulk Solution for High Volume Production

To address high-volume production challenges, MapleJet offers the Hx Carto. This bulk solution is designed for large-scale operations, offering robust performance, high-speed printing, and reliability. The Hx Cartro integrates seamlessly into any existing production line, ensuring high-quality codes necessary for traceability and compliance. This solution allows large manufacturers to maintain continuous operation without compromising print quality.

Coming Soon: The MapleJet Hx Nitro 25w for Low to Medium Volume Production

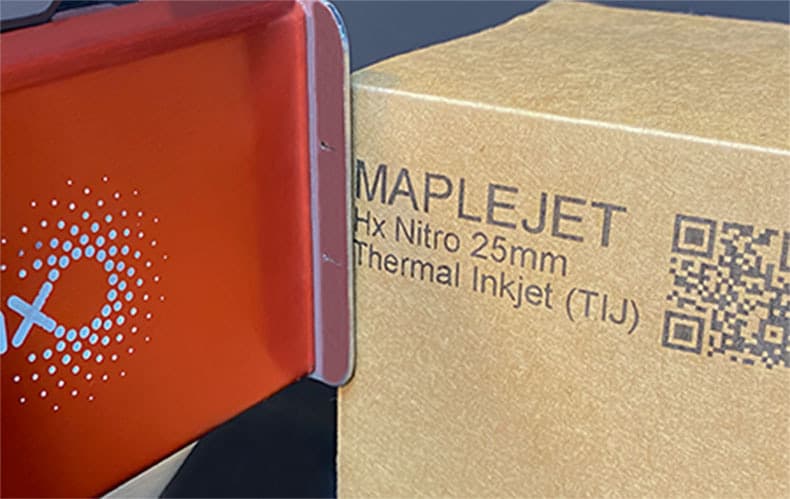

MapleJet continues to innovate with the upcoming Hx Nitro25w. This new addition is tailored for low to medium volume productions but is equally capable of meeting the demands of larger companies seeking flexible, plug-and-play solutions for smaller production lines or special packaging runs.

The Hx Nitro 25w is a maintenance-free 25mm (1in) single head, water-based thermal inkjet (TIJ) printer that represents a significant leap in coding technology. It is designed to be user-friendly, with a focus on ease of installation and operation. Its plug-and-play capability makes it ideal for companies that require a quick setup with minimal intervention. The maintenance-free aspect is particularly appealing to SMEs that may not have the extensive technical support that larger companies possess. It’s perfect for GS1 2D barcode printing, ensuring accuracy and compliance. Plus, it’s the best choice for Sunrise 2027, making your transition smooth and hassle-free.

As the secondary packaging landscape continues to evolve, MapleJet remains at the forefront, offering cutting-edge solutions. Whether handling the demands of high-volume production with the Hx Cartro or providing versatile solutions like the Hx Nitro 25w, MapleJet is dedicated to enhancing productivity and efficiency across all production levels. Explore how our solutions can transform your secondary packaging process by visiting our website or contacting our sales team.

Recent Comments