Industry 4.0 is more than just automation—it’s about creating connected, intelligent, and agile production environments that benefit every person and process. Whether you’re running a small-batch production line or a multi-facility operation, the MapleJet Hx Nitro Thermal Inkjet Printer is designed to bring the future of coding and marking directly to your business.

This is not just another printer—it’s a smart, scalable, and sustainable solution that replaces outdated CIJ, TTO, and cheap generic TIJ technologies. With advanced connectivity, real-time control, and unmatched ease of use, Hx Nitro delivers on the true promise of Industry 4.0—for every role in your organization.

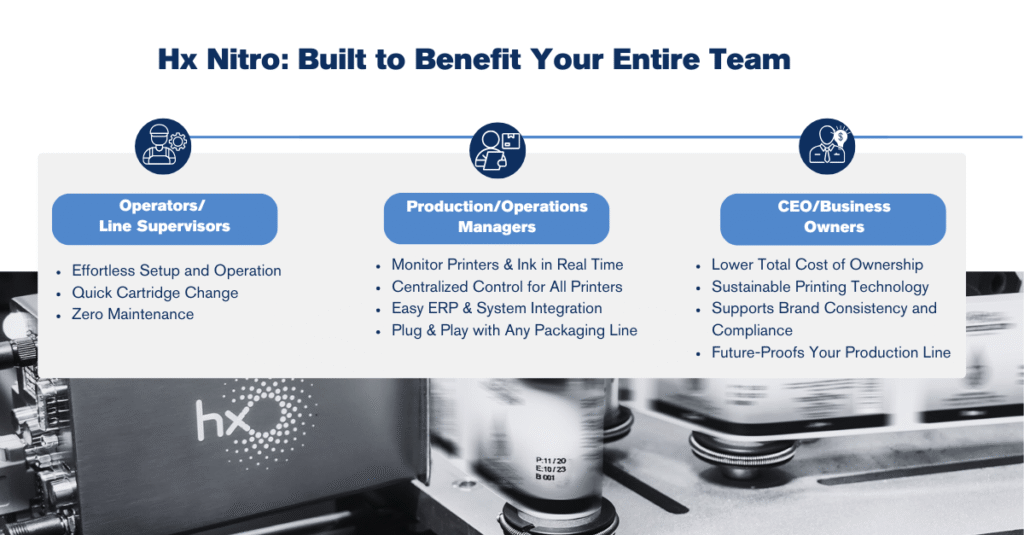

Operators & Line Supervisors: Make Everyday Tasks Easier

Operators need solutions that are fast, simple, and consistent. Hx Nitro delivers an experience designed for real production floors:

- ✅ Effortless Setup and Operation

Use Hx Manager from any smart device—no technical background needed. Start, stop, or adjust print jobs on the fly without halting production. - ✅ Fast Cartridge Swaps

Quickly switch cartridges based on the packaging material—ideal for small lines handling varied SKUs with minimal downtime. - ✅ Zero Maintenance, No Mess

No daily cleaning or complex shutdowns. Just plug, print, and go—unlike CIJ systems that require extensive maintenance and solvent handling.

🔍 Impact: Reduce operator stress, avoid errors, and boost daily productivity.

Production Managers: Full Control Without the Complexity

For production managers juggling uptime, quality, and cost-efficiency, Hx Nitro offers unmatched visibility and responsiveness:

- ✅ Real-Time Monitoring Across Lines

Track multiple printers and ink consumption via Hx Console, with performance insights, alerts, and usage reports at your fingertips. - ✅ Instant Message Editing

Change product codes, batch numbers, or expiry dates instantly—no downtime, no technician required. - ✅ High-Speed, High-Quality Output

Print up to 240 meters per minute with razor-sharp clarity, even on fast-moving lines.

🔍 Impact: Increase throughput while maintaining coding accuracy and traceability.

Operations Managers: Seamless System Integration

Operations teams need technology that plays well with existing infrastructure. Hx Nitro is built for modern, connected factories:

- ✅ API Integration with ERP, MES, and BI Systems

Streamline coding workflows and eliminate manual inputs—perfect for smart factory ecosystems. - ✅ Built for Packaging Line Integration

Easily integrate with VFFS, HFFS, labelers, or standard conveyor. - ✅ Reliable, Scalable Deployment

Whether you’re running one printer or a network of 50, scale operations easily with a unified interface.

🔍 Impact: Drive automation, reduce human error, and ensure real-time coordination across departments.

CEOs & Business Leaders: Smarter Investment, Stronger ROI

Leadership teams need solutions that future-proof operations while reducing the total cost of ownership:

- ✅ Sustainable Printing Technology

No mess, no extra solvents needed—Hx Nitro uses compact, pre-mixed solvent and semi-solvent ink cartridges with lower VOC emissions compared to CIJ, making it cleaner, safer, and more efficient for your production environment. - ✅ Lower Total Cost of Ownership

With zero maintenance, no downtime, and no spare parts needed, Hx Nitro delivers long-term savings over CIJ and TTO systems. - ✅ Supports Brand Consistency and Compliance

Ensure precise, readable codes that meet global traceability and labeling standards.

🔍 Impact: Lower operating costs, support ESG goals, and showcase innovation leadership.

Fits Any Company Size, Any Production Line

Whether you’re a startup manufacturer or a multi-national facility, Hx Nitro adapts:

- Small Lines benefit from low maintenance, ease of use, and cartridge flexibility.

- Medium Lines enjoy mid-volume efficiency with centralized control and automation readiness.

- Large Production Lines leverage high-speed performance, smart system integration, and multi-printer coordination.

Replacing CIJ, TTO, and cheap generic TIJ: The Time Is Now

Why stick with aging technology that slows you down?

| Technology | Drawbacks | Hx Nitro Advantages |

| CIJ | Requires daily maintenance, high VOC, and high operating costs | Maintenance-free, low VOC, clean operation |

| TTO | Limited integration, mechanical wear, expensive ribbon waste | No moving parts, high-adhesion, fast-drying inks for sharp branding |

| Cheap generic TIJ | No advanced connectivity, limited ink options | High-resolution printing, cloud-enabled, diverse ink compatibility |

🔁 Switching to Hx Nitro means fewer breakdowns, easier integration, and a faster return on investment.

The Future of Coding and Marking Is Here

MapleJet’s Hx Nitro isn’t just a printer—it’s a strategic enabler for modern manufacturing. By delivering smart connectivity, flexible scalability, and universal usability, it empowers every role to perform at their best in an Industry 4.0 world.

✅ Upgrade your line.

✅ Empower your people.

✅ Future-proof your production.

🔗 Explore Hx Nitro Now

Or book a live demo to see how it can elevate your team—from operator to CEO.

Recent Comments