For years, manufacturers have faced a difficult choice in product coding and marking: Thermal Inkjet (TIJ) for its precision and simplicity, or Continuous Inkjet (CIJ) for nonstop reliability. Both technologies have defined the packaging industry, but each comes with trade-offs—downtime, maintenance, consumable costs, or limits on substrates. These compromises are no longer acceptable in today’s market, where compliance, efficiency, and sustainability directly affect profitability and customer trust..

To address this challenge, Maplejet has created a new category of coding and marking: Continuous Thermal Inkjet (CTIJ). CTIJ is not a step forward in inkjet—it is a redefinition of what industrial coding can achieve. By combining the characteristics of the zero-maintenance and ease of TIJ with the robustness and uptime of CIJ, CTIJ eliminates the weaknesses of both. For executives and production leaders, this means fewer stoppages, lower costs, and greater certainty in meeting compliance and operational targets.

The Legacy of TIJ and CIJ

TIJ’s Role in the Market

TIJ established itself as the coding solution of choice where sharp, scannable codes were critical. Pharmaceutical packaging, food labels, and consumer goods cartons benefitted from TIJ’s high-resolution output and cartridge simplicity. For operators, plug-and-play cartridges reduced training and minimized errors. Yet TIJ also carried hidden costs: frequent cartridge changeovers disrupted uptime, ink portfolios were limited, and consumable expenses climbed in high-volume environments.

CIJ’s Role in the Market

CIJ earned its dominance on fast-moving production lines where uptime and ink adhesion on diverse substrates—plastics, metals, glass—were non-negotiable. Its continuous ink circulation made it ideal for high-speed coding, but at a price: lower print resolution, higher maintenance, and greater environmental impact due to solvent inks and fluid waste.

Together, TIJ and CIJ defined the industry, but they forced production leaders into a “quality vs. uptime” trade-off that slowed innovation.

CTIJ: The Hybrid Solution

CTIJ bridges the divide. It delivers the 600 dpi clarity of TIJ with the nonstop operation of CIJ, enabling manufacturers to meet modern requirements without compromise. Built on Brady’s industrial-grade TIJ cartridge technology, CTIJ offers:

- Industrial durability – engineered for vibration, dust, and continuous production.

- Reliable ink delivery – closed-loop pressure systems and quality feedback ensure consistency at high speeds.

- Versatile ink options – water-based and semi-solvent inks for cartons, plastics, foils, bottles, cans, and corrugated boxes.

- No-stop operation – hot-swappable cartridges eliminate downtime during changeovers.

This combination creates a platform that is compliance-ready, cost-efficient, and future-proof.

Where These Technologies Are Used

- Traditional TIJ remains useful for shorter runs, carton coding, and pharmaceutical applications where clarity is paramount and downtime is manageable.

- CIJ still serves in environments where solvent-based coding on glass or plastics is required, despite its heavy maintenance load.

- CTIJ, however, is the clear choice for mainstream, high-volume production where uptime, compliance, and cost-efficiency must coexist. It is particularly valuable in food, beverage, and pharmaceutical industries, where regulatory demands and brand protection leave no room for error.

Comparison of Coding Technologies

| Feature | Thermal Inkjet (TIJ) | Continuous Inkjet (CIJ) | Continuous Thermal Inkjet (CTIJ) |

| Print Quality | High (up to 600 dpi) | Low–Medium (60–120 dpi) | High (up to 600 dpi) |

| Operation | Intermittent (cartridge-based) | Continuous (bulk ink system) | Continuous with cartridge hot-swap |

| Ink Options | Limited, best on porous substrates, and some non-porous substrates | Wide, suitable for plastics, glass, metals | Wide, suitable for plastics, glass, metal |

| Maintenance | Minimal | High (requires servicing, filters, pumps) | Minimal, closed-loop pressure system |

| Uptime | Limited by cartridge changes | High | High (no-stop design) |

| Applications | Cartons, labels, pharma packs, flexible films | Plastics, metals, glass, bottles | Plastics, cans, glass, metals, bottles |

What CTIJ Means for the Market

The arrival of CTIJ signals a turning point for the coding and marking industry. For years, manufacturers have had to compromise: accept TIJ’s maintenance-free simplicity but live with downtime, or embrace CIJ’s nonstop reliability but bear the burden of servicing and consumables. CTIJ eliminates this choice by delivering both in a single platform.

For executives, CTIJ means:

- Assured compliance with Sunrise 2027 and GS1 barcode standards.

- Reduced operating costs through longer head life and bulk-ink options.

- Improved efficiency and profitability by minimizing stoppages.

- Alignment with sustainability goals, thanks to lower VOC emissions and reduced cartridge waste.

In practice, CTIJ gives packaging lines the ability to run smarter, faster, and longer, unlocking measurable gains in efficiency and business continuity.

Looking Ahead: Hx Ultimo CTIJ at Pack Expo 2025

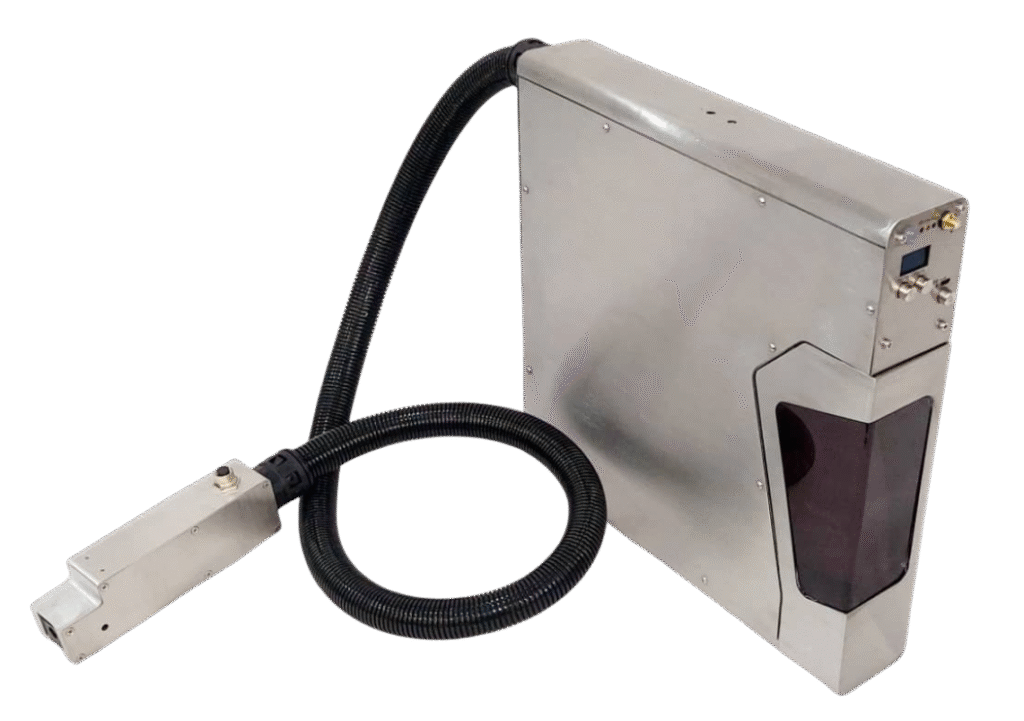

Maplejet’s Hx Ultimo CTIJ, which debuted at Pack Expo 2025, embodies this breakthrough. Designed for bottles, cans, and complex curved surfaces, it combines high-throw capability, aggressive ink formulations, and nonstop reliability in a single system. For decision-makers, this is not just a new printer—it is a strategic investment in resilience, compliance, and competitiveness.

Equally important, CTIJ is already a validated technology. Since 2022, Maplejet’s Hx Ultro bulk-ink CTIJ has been running successfully in high-volume flexible packaging lines worldwide. Its fully automated bulk ink delivery, combined with zero-maintenance operation, has proven CTIJ’s ability to deliver sustained performance in demanding industrial environments. This track record offers clear proof that the technology is not theoretical—it is real, reliable, and ready.

Conclusion

The market has long been divided between the clarity of TIJ and the uptime of CIJ. CTIJ bridges that divide. It is not merely an upgrade, but a new category of technology that allows manufacturers to print with confidence, compliance, and conscience.

For production managers, it means fewer stoppages and reliable performance. For senior executives, it means protecting market access, reducing costs, and preparing the business for the future of global packaging.

And with both the field-proven Hx Ultro and the upcoming Hx Ultimo, Maplejet demonstrates that CTIJ is more than an innovation—it is the new standard for industrial coding and marking.

The future of coding is continuous. The future of coding is CTIJ.

Recent Comments