CTIJ Printing Technology for Packaging Lines: How It Works, Benefits & Why It’s Taking Over

Manufacturers are under pressure to keep packaging lines running faster, cleaner, and with fewer operator interventions. At the same time, coding requirements are increasing—more traceability, better barcode readability, and more consistency across shifts.

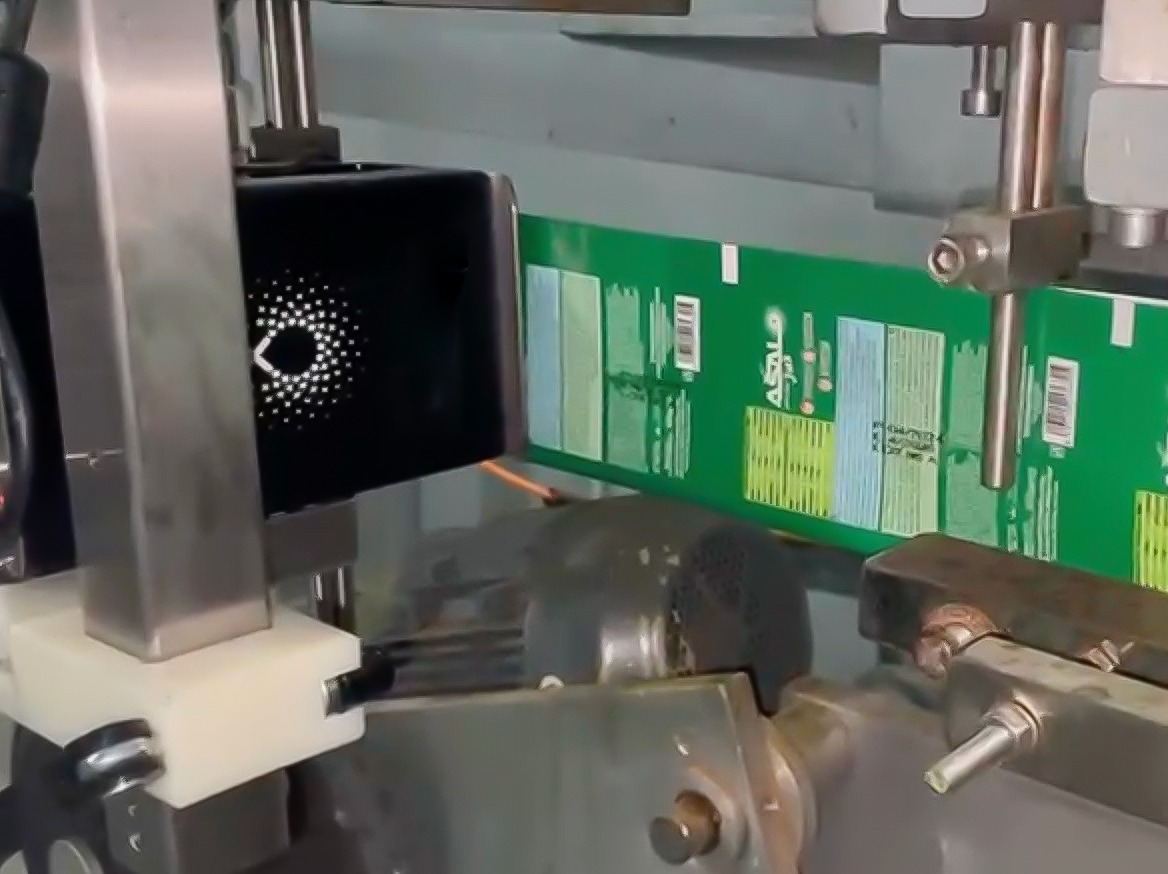

That’s where CTIJ (Continuous Thermal Inkjet) is gaining attention. It’s designed for high-volume packaging environments that need reliable uptime, high-resolution print, and a cleaner operating footprint.

What Is CTIJ Printing?

CTIJ (Continuous Thermal Inkjet) is an industrial coding technology that combines:

- The clean, high-resolution print performance of TIJ

- The nonstop, production-line reliability typically associated with CIJ

Think of CTIJ like this:

- It prints like TIJ (sharp, high-resolution marks)

- It runs like CIJ (built for continuous, multi-shift production)

- It stays cleaner than CIJ because the ink path is sealed and non-circulating

How CTIJ Works (In Plain Terms)

CTIJ uses a sealed bulk ink system and precision-regulated pressure to keep ink delivery stable at high speeds.

That stability matters because it helps maintain:

- consistent droplet formation

- consistent optical density

- consistent print quality—especially at higher production speeds

What makes CTIJ different mechanically

From an “ownership and uptime” perspective, CTIJ’s defining design traits are:

- Closed, non-circulating ink path (less mess, fewer contamination points)

- Gravity-independent ink feed (more flexible installation on real packaging machinery)

- Hot-swappable ink bags (swap ink without stopping the line)

This is the foundation of why CTIJ is becoming attractive to modern plants trying to reduce

downtime and operator involvement.

CTIJ vs CIJ vs TIJ: The Practical Buyer View

| Technology | What it’s known for | Common operational reality | Best fit |

| CIJ | Versatility + high uptime | More fluid handling, more maintenance systems | Mixed substrates, harsh environments, legacy CIJ lines |

| TIJ | Clean, sharp print | Cartridge changes in higher-duty use | Simple lines, small-to mid scale, easy ownership |

| CTIJ | TIJ print + continuous production | Sealed bulk ink + less routine intervention | High-volume packaging lines prioritizing cleanliness + uptime |

Why CTIJ Is Gaining Traction Globally

1. Cleaner operation is no longer “nice to have”

Hygiene, safety, and audit-readiness matter more today than they did even five years ago.

CTIJ supports this because it uses a closed, non-circulating ink path that enables cleaner operation.

What this solves on the floor:

- less ink handling

- fewer spill points

- less contamination risk around packaging equipment

2. It eliminates the “messy ink system” problem

CTIJ’s bulk ink design is engineered around a sealed system and regulated ink delivery —not an open, circulating fluid approach.

Why buyers care:

- less cleanup time

- fewer “small issues” that turn into downtime

- more predictable day-to-day operation

3. It matches what modern packaging lines require

Packaging lines today demand:

- high resolution (especially for QR/data codes)

- high-speed reliability

- simple integration and monitoring

CTIJ platforms are positioned for speed, seamless integration, and low cost per print in high-volume environments.

Plus, CTIJ systems commonly support:

- real-time monitoring

- web-based interface (no app required)

- centralized multi-printer monitoring and control

That’s the language of modern packaging operations: visibility, control, and scalability.

Where CTIJ Fits Best in the Real World

CTIJ is designed for high-volume, multi-shift production that needs uninterrupted printing and consistent output.

Strong-fit applications

- FMCG cartons / paperboard

- E-commerce cartons, warehousing, distribution centers

- Flexible packaging in pharma, cosmetics, food

End-User Benefits (What Your Team Actually Gains)

Lower downtime

Hot-swappable ink bags are designed to allow uninterrupted printing, supporting continuous production.

Operational impact:

- fewer stops for consumables

- fewer operator interventions

- more consistent output across shifts

Cleaner factories

The closed, non-circulating ink path supports cleaner operation and reduces the day-to-day mess that often accumulates around coding stations

Easier ownership

CTIJ targets maintenance-free performance for high-volume, multi-shift lines —meaning less routine upkeep, less troubleshooting, and simpler training compared to more complex fluid-handling systems.

Commercial Insight: Why Buyers Are Switching (Without the Hype)

CTIJ adoption is rarely about “new tech for the sake of new tech.”

It’s a commercial decision driven by:

- downtime cost per hour

- operator availability and training time

- audit and cleanliness requirements

- code quality consistency (especially for scan reliability)

When production is high volume and continuous, predictability often beats “maximum versatility.” CTIJ is trending because it reduces ownership complexity while maintaining lineready uptime.

Conclusion: The Clear Takeaway

CTIJ is becoming the preferred coding technology on modern packaging lines because it addresses three realities manufacturers care about:

- Cleaner operation (closed ink path)

- No messy ink system (sealed bulk ink + controlled delivery)

- Designed for modern, high-volume lines (continuous operation, monitoring, integration)

If your priority is lower downtime, cleaner production areas, and easier ownership, CTIJ deserves a serious look during any CIJ replacement or line expansion project.

Recent Comments