Why Traditional Coding Technologies Face Limits?

Industrial printing and coding systems are critical to packaging and manufacturing operations. Over time, several technologies have become mainstream: Continuous Inkjet (CIJ), Thermal Inkjet (TIJ), and Thermal Transfer Overprint (TTO). Each technology is built on different physical principles and design philosophies, which means each brings distinct strengths and inherent limitations.

In this article, we do not compare units or printer models; instead, we compare technologies. The aim is to provide a clear technical understanding of how CIJ, TIJ, and TTO function, what their challenges are, and how Continuous Thermal Inkjet (CTIJ) — a technology already proven in real industrial use — presents a new direction in coding.

CIJ: Powerful but Complex and Maintenance-Heavy

CIJ works by continuously forcing liquid ink through a nozzle, where the ink stream breaks into thousands of uniform drops per second. These drops are charged and steered by an electrostatic field to form characters or graphics on the substrate. Drops not required for printing are redirected into a gutter, recovered, and filtered back into the system. Because most CIJ systems use volatile MEK-based inks, evaporation constantly changes the viscosity.

To keep print consistent, CIJ printers must add make-up solvent, measure viscosity with precision sensors, and rely on multiple pumps and filters. The printhead also operates under high-voltage conditions with complex timing electronics. This sophistication makes CIJ powerful but inevitably increases maintenance demands and operating costs.

- It generates a continuous stream of drops at high frequency.

- Drops are charged and deflected by high-voltage plates to form characters.

- Unused drops are recovered through a gutter vacuum system.

To maintain stable performance, CIJ requires:

- A viscometer to correct for solvent evaporation (common MEK inks are highly volatile).

- Continuous make-up solvent addition.

- Multiple pumps, filters, suction, high-voltage circuits, and precise phase control for droplet formation.

While CIJ is powerful and flexible, its dependence on so many subsystems makes it complex, costly, and maintenance-heavy.

Standard TIJ: High Precision, Low Volume, Frequent Stoppages

TIJ operates by instantly heating a tiny amount of ink inside a chamber with a micro-resistor. The vapour bubble expands and ejects an ink droplet through the nozzle. Once the bubble collapses, the chamber refills for the next cycle. This process is simple, precise, and capable of extremely high-resolution printing.

However, TIJ cartridges are inherently small. In industrial-scale production, this means cartridges need to be replaced frequently, especially on high-speed lines. Even with larger cartridges, frequent stoppages remain a bottleneck. TIJ is excellent for applications with moderate duty cycles but less efficient for continuous high-volume coding.

- TIJ cartridges are clean, simple, and deliver high-resolution print.

- Operation is straightforward with minimal maintenance.

However:

- Ink capacity is limited, especially for standard cartridges.

- On high-speed or continuous production lines, cartridges must be replaced frequently.

- Even extended-capacity cartridges do not fully solve the stoppage problem, making TIJ less efficient in demanding industrial applications.

- TIJ cartridges often have contact pads or spring pins that connect them to the controller. These can be physically damaged if the cartridge is not inserted carefully, leading to cartridge wear or electrical contact issues, even when the cartridge still has ink.

TTO: High Quality but Interruptive and Consumable-Heavy

TTO is widely used on flexible packaging lines, such as pillow packs and film wraps. A heated printhead presses against an ink-coated ribbon, transferring the image directly to the substrate. This produces sharp, high-quality codes suitable for dates, barcodes, and lot information.

The main drawback is consumable handling. Ribbons need to be changed frequently, and every change requires stopping the machine. Additionally, the printhead itself wears with use and must eventually be replaced. While TTO delivers strong quality for flexible films, the maintenance interruptions and consumable costs limit efficiency in high-volume environments.

- A heated printhead transfers ink from a ribbon onto the substrate.

- The method provides high print quality and is well-suited to variable data printing on films and foils.

Limitations include:

- Ribbons must be replaced regularly, leading to production stoppages.

- The thermal printhead itself wears over time and must be periodically replaced, adding cost and downtime.

- Frequent consumable handling reduces overall efficiency compared to non-contact technologies.

CTIJ: Continuous, Reliable, Industrial-Grade

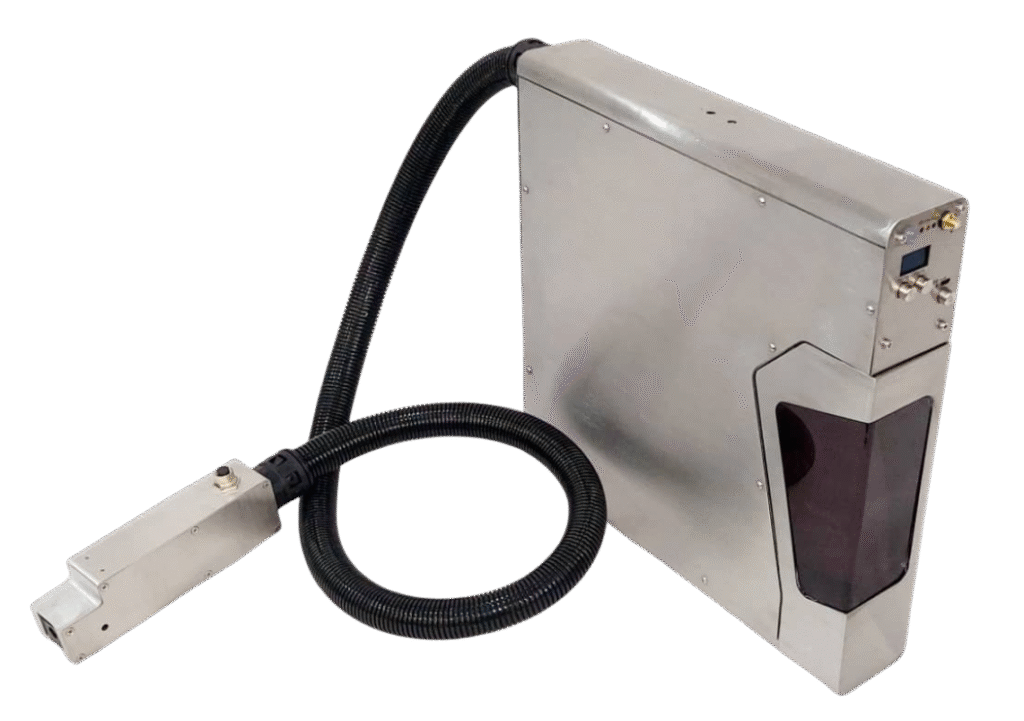

CTIJ builds directly on TIJ physics — heating resistors form bubbles that eject drops with precision. However, instead of relying on small disposable cartridges, CTIJ connects the printhead to a bulk ink delivery system. A high-precision pressure sensor constantly monitors the ink chamber, while a smart delivery algorithm ensures stable pressure, adapting to real-time consumption. This guarantees consistent ink flow under varying conditions.

One of CTIJ’s most important advantages is its continuous operation design. A small buffer reservoir within the printhead keeps several millilitres of ink available at all times. When the main ink cassette is replaced, the printer continues drawing from the buffer, so the line never stops. This eliminates the downtime problem of TIJ and the consumable complexity of TTO.

CTIJ has been proven in real industrial settings. First employed in the MapleJet Hx Ultro, it has operated in factories for years under high-duty cycles, consistently achieving more than two (2) litres of ink output per cartridge, with some cases surpassing five (5) litres. Building on this success, the technology was extended to the Hx Ultimo, demonstrating scalability across different packaging types, from flexible films to rigid cans and bottles.

Beyond volume, CTIJ delivers additional operational advantages. Because of its TIJ-based architecture, it can print multiple lines in a message without reducing linear speed, unlike CIJ. For flexible packaging, the complementary CodeMax system provides an ergonomic mechanical stand, simplifying roll handling and maintenance. Cartridge capacity is also optimized for industrial environments—depending on conditions of use and ink type, cartridges can consume between 2–10 liters of ink. In particular, Brady cartridges stand out for their industrial-grade construction, making them highly reliable for heavy-volume bulk applications compared to other cartridges on the market. Together, these features establish CTIJ as a practical, efficient, and industrial-grade technology.

Core Principle

- CTIJ uses Funai (Brady) TIJ printheads — proven, high-quality components trusted in the market.

- The mechanism is the same as TIJ: a thermal resistor creates a bubble to eject ink through nozzles with precision and reliability.

- What makes CTIJ different is the continuous bulk ink system attached to the TIJ printhead.

Intelligent Ink Management

- A high-precision pressure sensor continuously monitors the pressure inside the printhead.

- A smart ink delivery system, regulated by advanced algorithms, adjusts flow in real-time to maintain optimal pressure balance.

- This guarantees a constant and stable ink supply, matching ink usage precisely.

Continuous Operation

- CTIJ maintains a buffer of several millilitres of ink in an internal chamber.

- This allows cassette changes during operation without stopping the line — printing continues seamlessly while the reservoir is replenished.

- It eliminates one of TIJ’s biggest limitations: stoppages due to small cartridge volumes.

Proven Industrial Reliability

- In real-world high-duty production, CTIJ cartridges consistently deliver at least two (2) litres of ink, with documented cases of over five (5) litres from a single cartridge.

- This is orders of magnitude beyond standard TIJ performance, establishing CTIJ as a true industrial technology.

Operational Advantages

- Multi-line Printing at Full Speed: Unlike CIJ, where adding message lines reduces throughput, CTIJ maintains linear print speed regardless of line count.

- Complementary System – CodeMax: For flexible packaging, CodeMax provides an ergonomic mechanical stand. It simplifies roll changes and maintenance, eliminating ribbon-related downtime common in TTO.

- Simplification: CTIJ requires no solvent makeup, no pumps, no viscometers, no ribbon changes, and no thermal head replacement.

CTIJ: A Category in Industrial Coding That has been around for years

CIJ, TIJ, and TTO each represent strong engineering solutions, but each carries inherent limitations in complexity, consumable handling, or scalability.

CTIJ represents an evolutionary step by combining:

- TIJ’s clarity and print precision,

- A continuous bulk ink system for industrial duty cycles,

- Simplified operation without solvent systems, ribbons, or frequent head replacements.

Proven in practice through the Hx Ultro and expanded in the Hx Ultimo, CTIJ has moved beyond concept to industrial reality. It provides manufacturers with a clean, continuous, and reliable coding solution, positioned to meet the growing demands of modern production lines.

Recent Comments