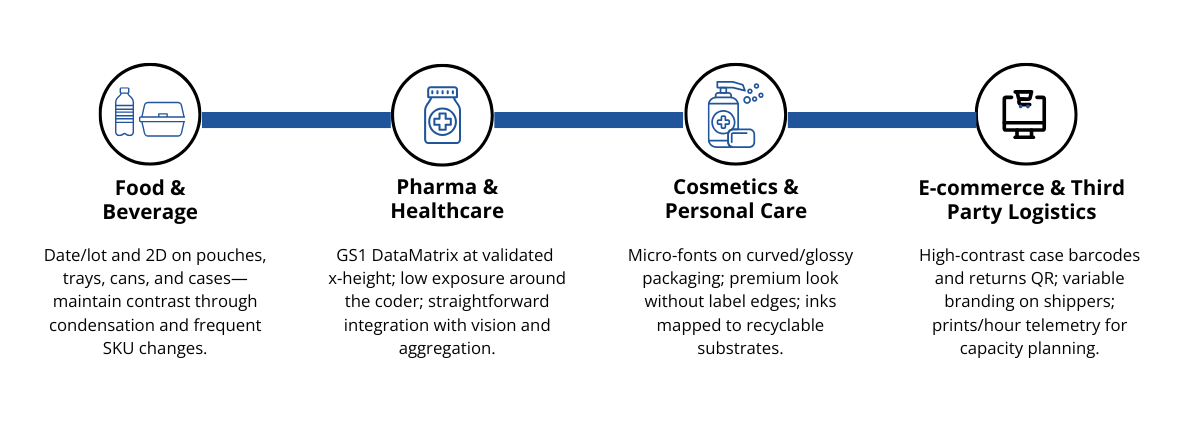

Packaging teams are being asked to do three hard things at once: add 2D barcodes ahead of GS1 Sunrise 2027, reduce waste, and raise uptime on high-mix, short-run lines. Most plants already know that Thermal Inkjet (TIJ) delivers crisp codes with low operator burden. The real question is how to make TIJ production-proof—hour after hour, changeover after changeover—without piling on labels, liners, and logistics.

MapleJet HX-Ultro™ answers that question with an operator-first TIJ platform and an on-printer Active Bulk Ink System (Active-BIS) that connects directly to Brady bulk TIJ cartridges. The ink supply lives at the line—not in a mail-back refill loop—so swaps are rare, purges are fewer, and quality stays steady through stops and starts. It’s a simple idea with big effects: less handling, less packaging, less scrap, more time actually printing.

What changes when bulk supply is on the printer—not in a shipping box

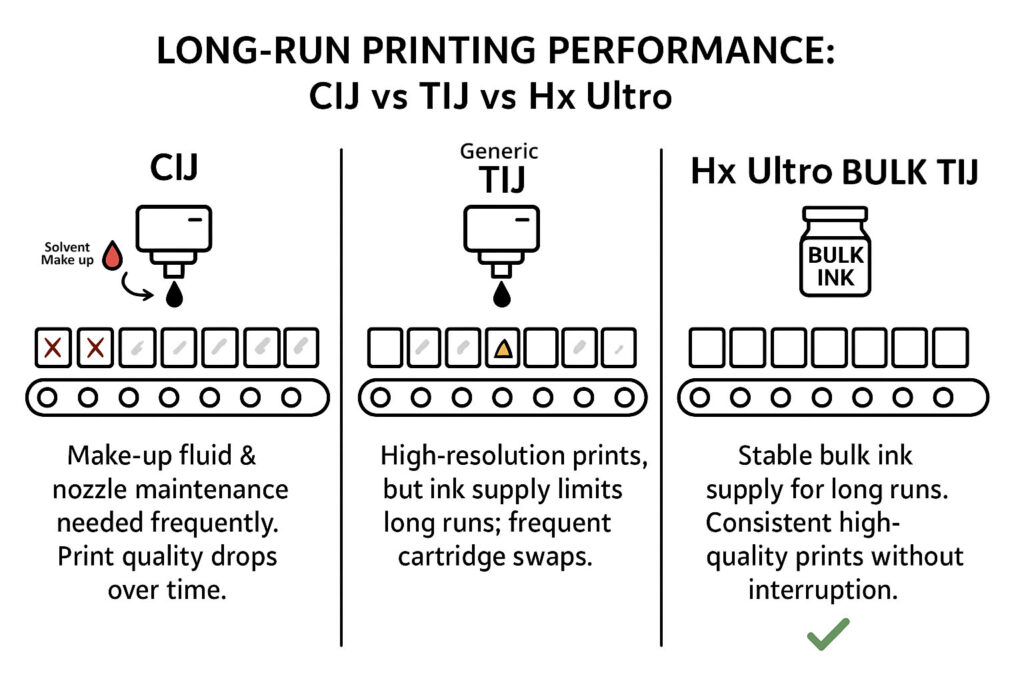

Fewer interruptions, more stable codes.

Bulk mounted on the line means fewer cartridge touches and far fewer changeover purges. Active-BIS actively manages the printhead’s operating conditions (meniscus/backpressure) so dot placement and density stay consistent—even when operators pause for micro-stops or accelerate after a format change.

Less material in, less material out.

Direct-on-pack TIJ removes label liners and adhesive waste for many SKUs. Putting bulk at the line also cuts the corrugate and courier miles tied to mail-back refills. The net is a quieter consumables footprint and a cleaner coder area.

Cost-per-mark that holds up at scale.

When duty cycles rise, basic TIJ can get expensive if you’re swapping often and purging frequently. Hx Ultro’s on-printer bulk and controlled replenishment compress those hidden costs so TIJ stays viable where it should—on pouches, trays, cases, glass, metal, and coated board.

Built for GS1 Sunrise 2027—without drama

2D that scans, shift after shift.

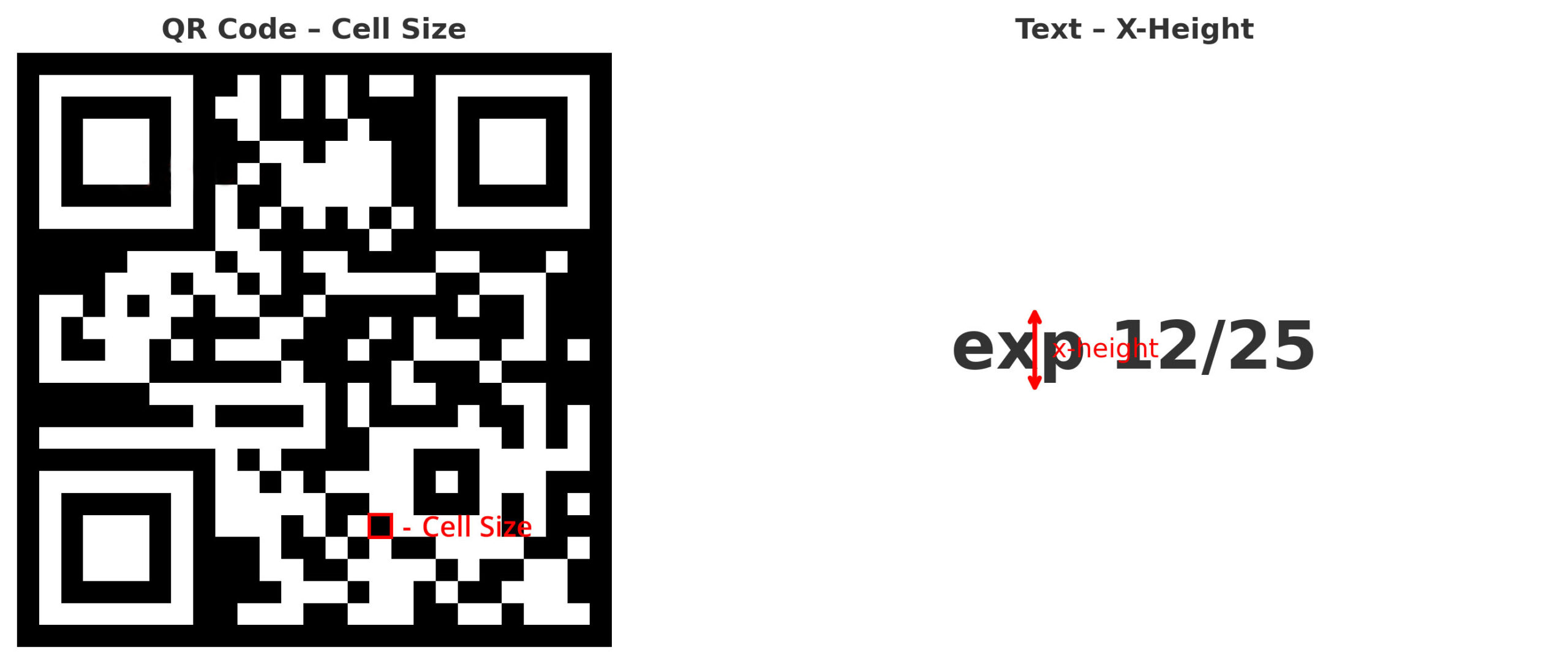

Hx Ultro ships with tuned 2D profiles (cell size/x-height guidance) for common retail specs, plus simple hooks to third-party vision systems for pass/fail checks and scan-rate validation. The point isn’t to over-engineer; it’s to print readable codes all day without babysitting the printer.

The right role for data.

Maplejet Cloud (AWS) currently collects throughput metrics—prints per hour—to support utilization and capacity trending. It’s not a traceability database, and we say that plainly. For content-level logging or audit trails, customers pair Hx Ultro with their preferred vision/QA platform.

Operator-first details that matter on a Tuesday at 3:15 p.m.

- One-touch job recalls and practical ERP/MES/PLC integration streamline changeovers and minimize keystroke errors.

- ABIS smooths restarts after pauses, so you don’t lose print density or waste product on the first few cartons after a pause.

- Substrate-mapped inks + setup playbooks help plants move from labels to direct coding on recycled board, high-slip films, glass, and coated metals—backed by durability guidance (rub/condensation/oil).

Sustainability where it counts (and how we count it)

Sustainability lives in the daily routine: fewer purges, fewer boxes, fewer label liners, fewer emergency calls. Hx Ultro aims at all four. Because the bulk supply sits at the line and Active-BIS reduces purge events, you use more of the ink you buy on actual product and send less packaging through your dock. That’s how coding should contribute to ESG—by being predictably efficient.

A practical view of TIJ vs. labels and CIJ

- Vs. labels: TIJ avoids liners and adhesive waste, and it keeps up with SKU churn without relabeling inventory. Hx Ultro’s bulk supply removes the swap burden that often pushes teams back to labels on high-mix lines.

- Vs. CIJ: TIJ eliminates make-up solvents and overspray concerns, with higher native resolution for small text and 2D. Hx Ultro closes the “duty-cycle gap” where TIJ historically struggled by stabilizing ink delivery over longer runs.

Why Hx Ultro is different from generic TIJ

- On-printer bulk, not mail-back refills → fewer swaps, fewer boxes, fewer miles.

- Active Bulk Ink System (Active-BIS) → stabilized meniscus/backpressure, consistent print quality.

- GS1-ready profiles + vision hooks → readable 2D without heroics.

- Factory-friendly connectivity → job recalls, ERP/MES/PLC links, and honest Cloud scope (prints/hour).

- Total-cost discipline → consumables you actually use on product, not in purges and packaging.

Questions every plant should ask (and how Hx Ultro answers)

How do you keep the head primed through starts/stops?

Active control of operating conditions at the printhead—so restarts don’t cost scrap.

Where does bulk live and who moves it around?

On the line, connected to Brady bulk TIJ cartridges. No mail-back refill loop, no shuttle of empties.

What proof do we get before we commit?

Substrate-specific samples, 2D readability at target cell sizes, and a line trial that measures OEE and waste deltas against your current setup.

What data do we see, and where?

Maplejet Cloud shows prints/hour for utilization and capacity trends; content-level QA lives in your vision/QA software via our straightforward integration.

Where Hx Ultro wins quickly

Make the next run your best run

TIJ is already the cleanest way to place high-value data on a pack. Hx Ultro turns it into the most dependable—by putting bulk supply at the line and control where it counts. If you’re staring down 2027 with more SKUs, tighter specs, and no time for drama, this is how you print smarter and waste less.

Ask us for the HX-Ultro 2027 Readiness Kit (2D profiles, substrate/ink playbook, and a simple sustainability/TCO calculator) and a no-disruption line trial with Brady bulk TIJ supply. We’ll prove it on your products, at your speed.

Recent Comments