Efficiency and precision are the backbone of every successful production line. In the coding and marking industry, these metrics are further amplified through smart integration. By connecting devices such as Programmable Logic Controllers (PLC), Enterprise Resource Planning (ERP) systems, and Systems Applications and Products (SAP), manufacturers can enhance operational capabilities and streamline workflows. Let’s explore the transformative role of Industry 4.0 smart integration and its impact on coding and marking processes.

Understanding Industry 4.0 Smart Integration

Smart integration is a broad term and is often used in many different scenarios, making it even more aloof. However, essentially, it refers to the seamless connection of different IoT systems and devices to facilitate smooth data exchange and operational coordination. In the coding and marking industry, this involves linking printing machines with PLCs and SAP systems to optimize production processes.

Integration with PLCs, ERP systems and SAP is essential because it allows for real-time data transfer and synchronization between production equipment and management systems. This connectivity ensures that operations are efficient and data-driven, leading to more informed decision-making and streamlined workflows.

Smart External System Integration in Coding and Marking

In the coding and marking industry, smart integration involves the incorporation of advanced technologies into coding machinery to interface effectively with external systems. This integration enables automated updates, precise data handling, and coordinated control across various stages of production.

- Protocol Compatibility: Smart integration requires compatibility between different communication protocols used by PLCs and SAP systems. Ensuring that marking equipment supports these protocols is crucial for effective integration.

- Data Exchange Mechanisms: Effective integration utilizes standardized data exchange formats such as XML, JSON, or CSV. This enables smooth data flow between marking systems and enterprise resource planning (ERP) systems like SAP, facilitating real-time updates and accurate data management.

- Automation and Control: Integration involves automating data transfer between systems to enhance control over marking processes. For instance, PLCs can automate marking operations based on real-time production data, adjusting parameters like print speed and content dynamically.

- Feedback Loops: Advanced integration includes feedback mechanisms that allow marking systems to send real-time status updates and error reports to PLCs and SAP systems. This enables immediate responses to production anomalies, reducing downtime and ensuring consistent quality.

Benefits of Smart External System Integration

- Increased Efficiency

- By automating data transfers and reducing manual interventions, smart integration accelerates production processes and minimizes downtime. This leads to a more efficient operation overall.

- Real-Time Data Access

- Integration with PLCs and SAP systems provides real-time data access, which enhances decision-making and operational responsiveness. This ensures that production lines operate smoothly and adjustments can be made promptly based on current data.

- Improved Accuracy

- Automated data exchange and synchronization reduce the likelihood of errors that can occur with manual data entry. This results in higher accuracy in coding and marking operations, contributing to better product quality and fewer errors.

- Enhanced Scalability

- Smart integration solutions are designed to be scalable, allowing businesses to easily adapt to changing production requirements and expand their systems without significant disruptions.

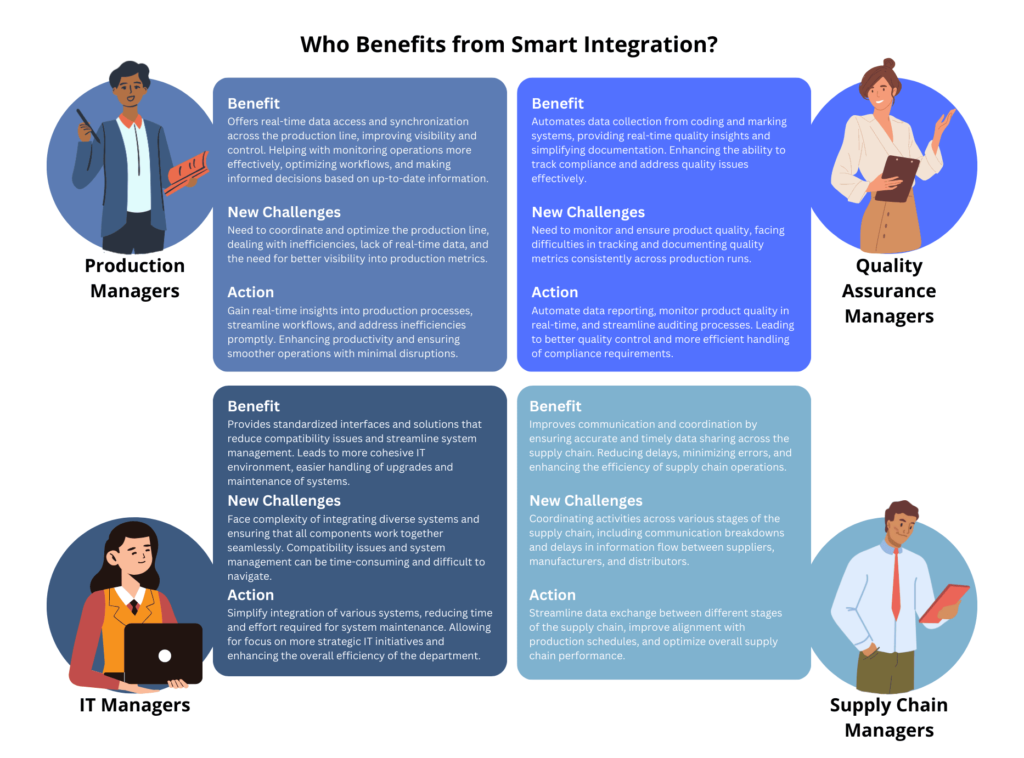

Who Benefits from Smart Integration?

Challenges in Smart Integration

- Compatibility Issues

- Outdated or diverse equipment may use different communication protocols and data formats, leading to compatibility problems. Ensuring that all systems can operate and communicate effectively is crucial.

- Data Synchronization

- Ensuring that data is accurately and consistently synchronized between systems can be complex and requires robust solutions to handle real-time updates.

- System Complexity

- Managing and integrating multiple systems can increase overall system complexity, which may create challenges for maintenance and troubleshooting procedures.

- Error Handling

- Automated systems need effective error-handling mechanisms and feedback loops to address issues quickly and prevent disruptions in production.

- loops to address issues quickly and prevent disruptions in production.

How MapleJet Addresses Smart Integration Challenges

- Seamless Compatibility

- MapleJet’s integration solutions are designed with broad compatibility in mind. This versatile approach allows for smooth integration across various platforms and legacy systems, reducing compatibility hurdles and facilitating cohesive operation.

- Real-Time Data Synchronization

- MapleJet employs advanced data exchange mechanisms to ensure real-time synchronization. Our systems use high-performance data protocols and integration frameworks that support accurate and timely data flow between marking equipment and ERP systems like SAP. This ensures that production data is always up-to-date, enhancing operational efficiency and minimizing discrepancies

- Simplified System Management

- To address system complexity, MapleJet offers user-friendly integration platforms that simplify system management. Our solutions include intuitive interfaces and comprehensive management tools that streamline integration processes. These features reduce the complexity of system management, allowing for easier configuration, monitoring, and troubleshooting.

- Advanced Error Handling

- MapleJet’s solutions are equipped with advanced error handling and diagnostic features. Our systems include automated alerts, real-time status updates, and comprehensive diagnostic tools that help identify and resolve issues quickly. This proactive approach to error management ensures smooth operation and minimizes production downtime, maintaining high-quality standards.

Smart integration is revolutionizing the coding and marking industry by enhancing efficiency, accuracy, and scalability. By addressing common challenges with advanced solutions, companies can achieve seamless operations and stay ahead in a competitive market. Explore how MapleJet’s innovative integration solutions can transform your operations and drive your business forward. The field of smart integration is continuously evolving with advancements in technology. Emerging trends include the adoption of AI and machine learning for predictive maintenance, enhanced IoT connectivity for smarter systems, and increased automation to enhance processes further. As these technologies advance, businesses will benefit from even greater efficiency and operational control and rest assured that MapleJet will always be at the forefront of all upcoming advancements.

Recent Comments