Are you currently optimizing your ceramics packaging today? First, product presentation and tight traceability remain absolutely critical globally. Specifically, choosing the right coding solution massively streamlines your daily factory operations….

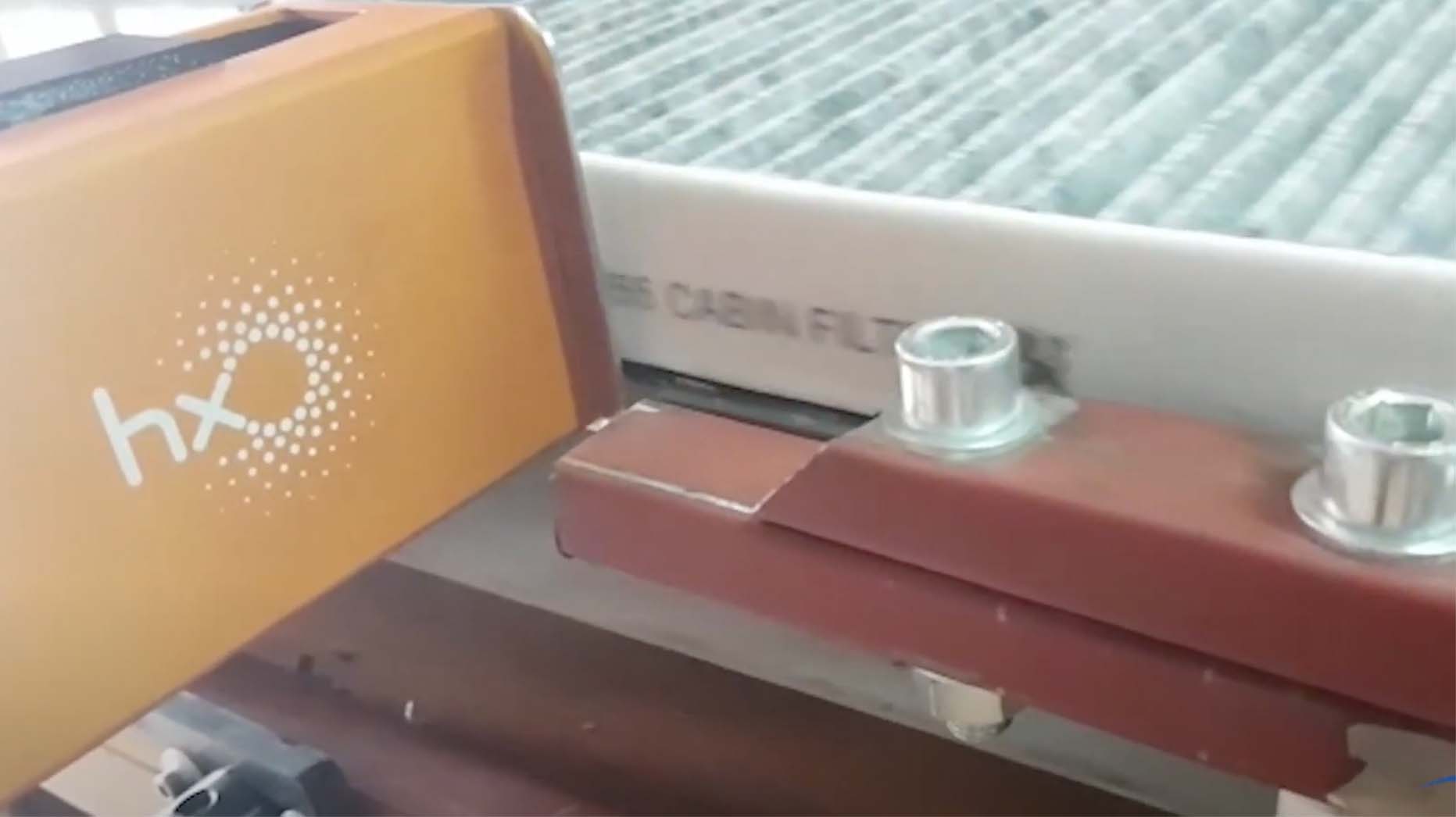

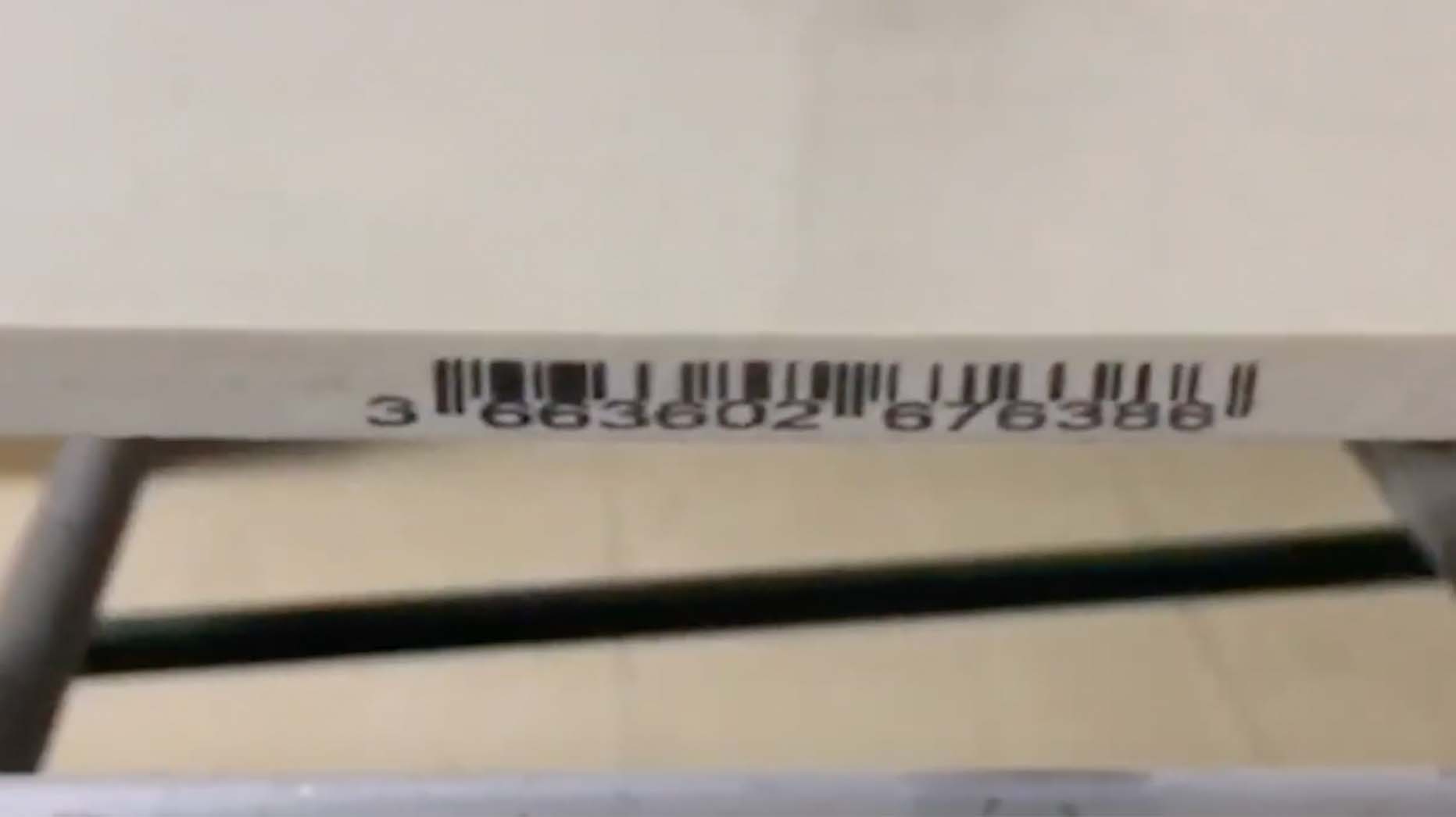

MapleJet’s printer’s durable design makes it ideal for rugged coding and product identification applications in the pipe, ceramic packaging, and industrial building materials.

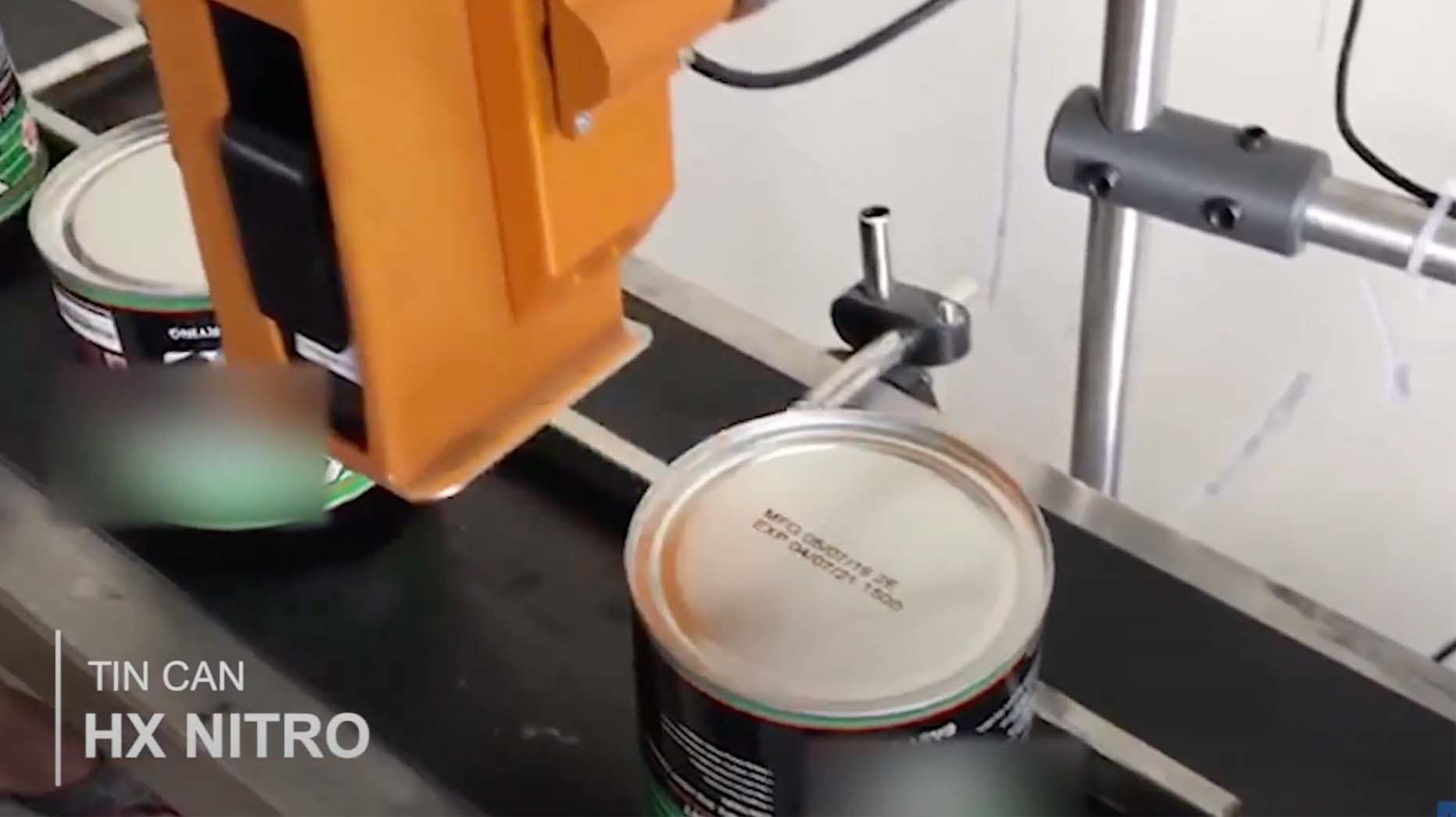

MapleJet printers offer high speed and quality coding onto a variety of industrial applications with different substrates. With high-quality printing, robustness for demanding environments, and reduction of packaging inventory, MapleJet coding and marking technology is widely used in applications including printing on thick cables/wires, chemicals, glass, construction materials, metals, lubricants, etc.

Click Hx Nitro for specifications and additional information.