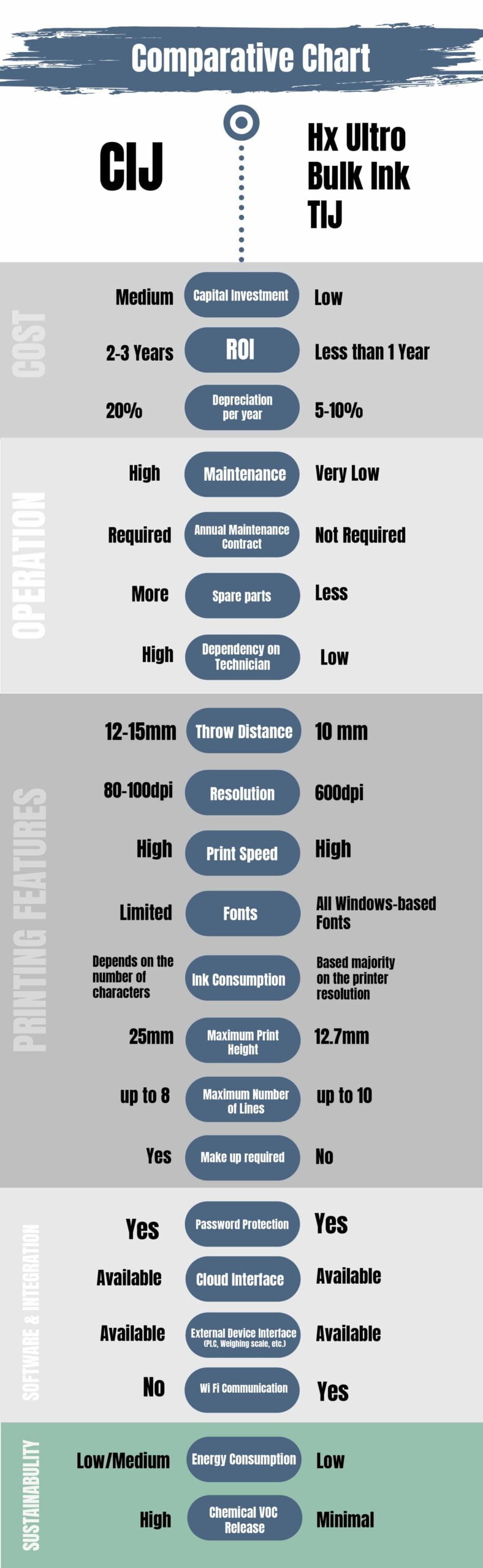

In the food industry, particularly for the sweet and snack packaging line, the ability to efficiently and accurately print codes and markings on the packaging is essential for product traceability, quality control, and regulatory compliance. Two common technologies used for coding and marking on food flexible packaging lines are Continuous Inkjet (CIJ) and Thermal Inkjet (Hx Ultro Bulk Ink TIJ) printers. While both technologies are capable of printing high-quality codes and markings, they differ in several key aspects, including cost, maintenance requirements, and printing abilities to name a few.

This article aims to give an insight into the differences between CIJ and Hx Ultro Bulk Ink TIJ printers and provide an overview of which technology may be best for your food flexible packaging applications.

How does a CIJ printer work?

Continuous Inkjet (CIJ) printers use a non-contact method to print on various surfaces by creating a continuous stream of ink droplets from a narrow orifice. Each droplet is charged by an electronic oscillator and selectively deflected by an electrostatic deflector plate to form characters or graphics. The uncharged droplets are recycled, while the charged droplets continue onto the substrate. The process occurs rapidly and continuously, allowing for high printing speeds and resolution even on complex surfaces.

How does a TIJ printer work?

Thermal Inkjet (TIJ) printing involves using a thermal printhead that uses tiny resistive heaters to vaporize a liquid into a gas. The gas creates bubbles and causes ink droplets to be ejected out of the nozzle, which lands on the substrate. TIJ printers offer higher-resolution printing and better image quality, making them ideal for producing detailed images.

How does Hx Ultro Bulk Ink TIJ Differ from a standard TIJ printer?

The Hx Ultro TIJ is equipped with a fully-automated bulk ink system consisting of precision ink pressure regulation and accurate pump ink feed that provides more ink volume than a standard TIJ cartridge. This reduces the need for frequent ink replacements; therefore, lowering operating costs, particularly for the high-volume food production line.

Five (5) Performance Metrics:

| Metrics | CIJ | Hx Ultro Solvent Bulk Ink TIJ |

| Operational Cost | Low cost of print The cost per print for Continuous Inkjet (CIJ) technology is low. However, the need for regular maintenance and the requirement for additional makeup fluid, along with the cost of an annual maintenance contract, can significantly impact the overall cost of operation. | Low cost of print The bulk ink system in a thermal inkjet (TIJ) printer offers more ink than a traditional TIJ system at a more favourable price, with low to zero maintenance required and no annual maintenance contract cost. In the long run, this makes the running cost to be comparatively lower than Continuous Inkjet (CIJ) printers. |

| Maintenance & Spare Parts | Regular Maintenance Continuous Inkjet (CIJ) printers may require a lot of factory maintenance yearly, incurring additional costs to maintain the printer’s optimal performance. Spare parts required The widespread use of Continuous Inkjet (CIJ) printers has made it easier to find and access replacement parts and maintenance materials at competitive prices. | No Regular Maintenance The MapleJet Hx Ultro has low to zero maintenance requirements, with the printhead only needing to be wiped when not in use, making it a cost-effective solution for coding and marking applications. Less Spare parts required One of the key benefits of Thermal Inkjet (TIJ) printers is their reduced number of moving parts, which minimizes the risk of breakage and reduces the need for extensive repairs. With the ability to replace individual components without the need for technical support, TIJ printers allow for quick, easy and even remote maintenance. |

| Ink Issue | Quick Ink change Although, the ink system in a CIJ printer is complex with multiple components working together to deliver the ink to the printhead, changing the ink is relatively easy. Prone to Ink mess CIJ uses a high-pressure pump to atomize the ink and project it onto the product. If there are any malfunctions or leaks in the system, the ink can spill onto the production floor and create a mess. | Quick ink change The bulk ink system in the Hx Ultro is simple, with fewer components. This makes the process of changing the ink straightforward and less prone to malfunctions or leaks. No Ink mess The cartridge-based design of Thermal Inkjet (TIJ) printers reduces the risk of spills and leaks, making them easier to maintain. The reduced maintenance requirements of TIJ printers include less frequent cleaning and fewer overall upkeep duties. |

| Printing Ability | Longer throw Distance Continuous Inkjet (CIJ) printers have the advantage of not requiring direct contact with the product being printed and can be positioned at a sufficient distance from the surface. This makes CIJ printers ideal for marking delicate or irregularly shaped products, such as those with curves or that may move or bounce during the production process. High-Speed Printing for Small Characters While CIJ printers are known for their high print speeds, sometimes reaching up to 500 meters per minute; it is important to note such high speeds may be ideal when printing one to two lines of a message. This is because the printer may not have enough time to properly form the characters or produce a clean and consistent print, which can result in smudging, bleeding, or unreadable characters. | Long throw Distance MapleJet state-of-the-art Bulk ink Thermal Inkjet (TIJ) printer now has the ability to print at distances up to 8mm, offering expanded capabilities for printing on a variety of surfaces. This includes curved, sloped, or recessed surfaces, making it an ideal solution for a wider range of applications that require high-resolution date code and barcode printing. Consistent High Speed Regardless of the Message One of its key strengths is its ability to deliver consistent high speed, up to 120 meters per minute, even at high resolutions. This makes it a reliable option for high-volume production environments where speed is of the essence. Unlike Continuous Inkjet (CIJ) printers, the Hx Ultro’s print speed is not dependent on the message content, meaning that it can deliver high-quality prints even for complex messages with a large number of characters or symbols. |

| Print Resolution | Maximum: 80 to 100 dpi Continuous Inkjet (CIJ) printing technology is a reliable and efficient solution for printing small characters and date codes in high-volume production environments, such as the food industry. However, the maximum print resolution is between 80 to 100 dpi; therefore when printing more characters of up to 4 lines or more, the printing speed of the printer needs to be adjusted to be able to print readable codes. | Maximum: 600 dpi TIJ printers are known for their outstanding resolution capabilities of up to 600 dpi. The TIJ technology can maintain a high-resolution print, even when operating at a fast speed, ensuring that these critical markings remain legible and accurate. |

When choosing between Continuous Ink Jet (CIJ) and Hx Ultro Bulk Ink Thermal Inkjet (TIJ) printers for food production line, it is important to consider factors such as print speed, cost of ownership, maintenance, and ease of use. While CIJ printers are faster and better suited for small character messages, they are also more expensive to maintain and require technical expertise to operate. On the other hand, Hx Ultro Bulk Ink TIJ printers have a lower cost of ownership, are more user-friendly, and offer high-resolution print quality even at high speeds, making them a cost-effective option in the long run. Ultimately, the choice between the two types of printers will depend on the specific needs of the production environment and the priorities of the business.

So the answer to whether Hx Ultro Solvent Bulk Ink TIJ can outperform CIJ printers in coding and marking for food flexible packaging depends on the specific priorities of the production line. But it’s worth noting that the emergence of Hx Ultro Bulk TIJ technology provides a viable alternative to the dominant CIJ technology, as it offers competitive advantages in terms of cost per print, ease of use, and high-quality printing.

Recent Comments