Home » Economy Mode Printing: Boost Hx Manager Printing Efficiency

Hx Nitro

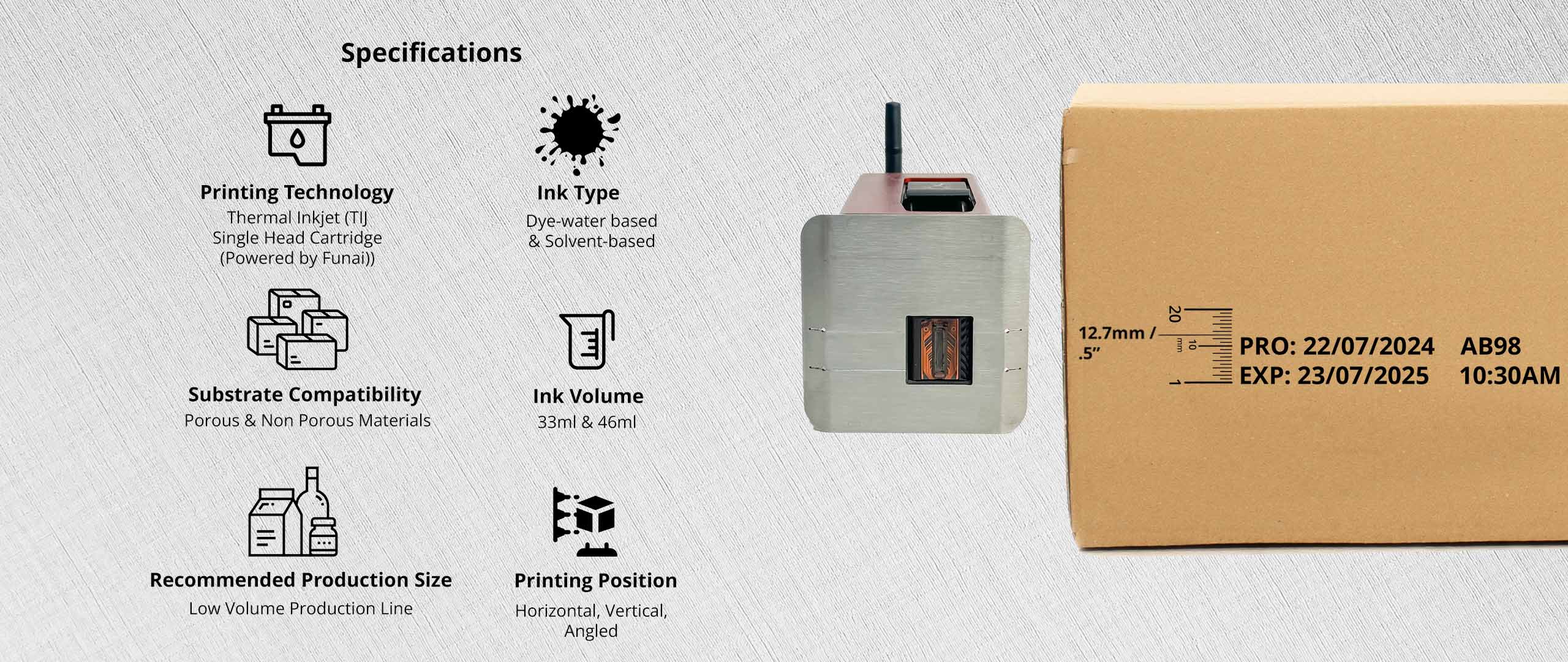

Industrial Thermal Inkjet Printer

Smart, Compact & Maintenance-Free Printing for SME Production Lines

In a world where speed, precision, and efficiency define manufacturing success, the Hx Nitro industrial inkjet printer delivers on every front. Designed for businesses that can’t afford delays, breakdowns, or inconsistent marking, this compact powerhouse ensures your products leave the line perfectly coded, every time.

Whether you’re scaling your operations or optimizing an existing line, the Hx Nitro helps you code smarter, faster, and more affordably, without compromising on quality.

Why the Hx Nitro is a Game-Changer

No Maintenance, No Downtime: With a smart cartridge system and advanced TIJ technology, Hx Nitro eliminates the headaches of traditional printers. No need for service contracts, cleaning cycles, or surprise technician visits.

600 DPI High-Resolution Coding: Print sharp, scannable codes — including batch numbers, expiry dates, barcodes, QR codes, shift IDs, logos, and counters — that meet even the most demanding retail and export packaging standards.

Wi-Fi Enabled, Mobile Controlled: Adjust your print messages from your phone, tablet, or PC. No extra hardware or complex software — just intuitive, real-time control on any device.

Lightweight & Easy to Integrate: Weighing just 750g, it fits seamlessly into conveyor systems, packaging lines, or compact manufacturing setups. A true plug-and-play coding solution.

Perfect Prints on Any Surface:

Whatever your packaging — bottles, cartons, pouches, or caps — the Hx Nitro ensures clear, durable, fast-drying prints.

- Plastic bottles (PET/HDPE)

- Glass surfaces

- Foil & laminated pouches

- Paperboard cartons

- Metal cans & lids

- Blister packaging

Ink Options for Every Packaging Type

- Boxtron Inks – For porous surfaces like cartons, kraft paper, and secondary packaging. Available in black, blue, and red.

- Chronplast-S & Chronplast-W Inks – Engineered for high-speed, non-porous applications like foil, laminated plastics, and varnished surfaces. Long-lasting, high-contrast results with rapid dry time.

- Eurex Inks – Specially formulated for high throw distance applications, perfect for coding on cans, curved surfaces, or uneven substrates. Ensures strong adhesion and legibility even from a distance.

- Aspro Ink – A white solvent-based ink designed for non-porous, dark, or transparent surfaces. Delivers bold, high-contrast marks with fast drying and excellent adhesion.

-

ADVANCED FEATURES

-

MESSAGE DESIGN

-

INK TYPES

-

HX NITRO PRINTER BROCHURE

MapleJet Cloud Integration:

- Real-Time Monitoring & Management: Access real-time production data, printer status, performance history, and downtime reports. Design messages and control printers remotely.

Hx Console:

- Printer Health Check: Monitor printer status with real-time warnings and suggested remedies for quick issue resolution.

- Economy Mode: Reduce ink consumption by 50%, increasing print output per cartridge and lowering costs.

- Field Upgrade: Enable future software upgrades, extending the printer’s lifecycle beyond industry standards.

- Auto Notify: Events such as ‘low ink level’, ‘printing completed’, and’online data received’ can be automatically communicated by choosing selected channels e.g. USB, RS232, and Wi Fi (HTTP)

- Auto Pilot: Allows other external device to control and monitor Hx Printer. Any third party device (e.g. PLC), system, or software can send a command to Hx Printer.

- Daily Production Report: Provides an hourly print report of the printer giving an overview of the complete daily production

- External Data: Easy integration to external devices e.g. PLC, weighing scale, etc for printing variable data. Auto calculation and printing of the product weight

- Ink Estimation Calculator: Provides an estimate number of prints per cartridge based on the message and other parameters.

Need ink flexibility? Switch cartridges easily without needing reconfiguration or technician support.

Smart Features That Matter to You

- Auto Ink Estimation: Know exactly how many prints you’ll get per cartridge. No surprises, no guesswork — just precise cost tracking.

- Economy Print Mode: Save up to 50% on ink while maintaining clarity. Ideal for high-volume runs where efficiency drives profitability.

- On-Device Print Reports: Get production data, print count summaries, and ink usage metrics — all accessible without external software.

- Remote Software Updates: Stay up to date with the latest features and improvements without interrupting your operations.

- Smart Health Check: Monitor print quality and performance in real time to avoid costly downtime or failed prints.

Packages That Fit Your Needs

- Hx Nitro Basic Package: Printer, product sensor, mounting brackets, power supply, built-in software. (Inks sold separately based on material compatibility)

Simple Message Editor:

- User-Friendly Interface: Offers a clean, intuitive interface designed for effortless navigation, enabling operators to create and modify messages quickly.

- Text Design: Create customized text for product labeling, batch codes, or other critical information, with options for various fonts, sizes, styles, and alignments.

- Production and Expiration Dates: Automatically generate production and expiration dates with customizable formats to meet regional and industry-specific compliance.

- Print Settings Control: Configure essential print settings, such as print speed, resolution, and direction, to ensure optimal print quality and efficiency for different substrates and production environments.

- Message Management: Save frequently used messages for easy retrieval, editing, and reuse, reducing setup times and improving production line efficiency.

- Encoder Parameters Activation: Seamlessly activate and configure encoder settings to synchronize printing with variable line speeds, ensuring consistent print quality regardless of production speed changes.

External Data Integration for Real-Time Printing:

- Dynamic Data Fields: Design messages that incorporate external data sources, such as product databases to print dynamic and real-time information, including serial numbers, batch codes, and more.

- Seamless Connectivity: Connect the printer directly to external data sources, enabling real-time data retrieval for on-the-fly printing without manual input or delays.

Perfect Prints on Any Surface:

Whatever your packaging — bottles, cartons, pouches, or caps — the Hx Nitro ensures clear, durable, fast-drying prints.

- Plastic bottles (PET/HDPE)

- Glass surfaces

- Foil & laminated pouches

- Paperboard cartons

- Metal cans & lids

- Blister packaging

MapleJet offers a versatile range of high-performance inks for the Hx Nitro TIJ printer, catering to various substrate needs including plastic, steel, aluminum, glass, metal, and wax-coated surfaces. Our ink lineup includes:

- Aspro (Solvent-based, white pigment) for general material applications on porous and non-porous surfaces.

- Boxtron SSD and Boxtron SSP (Semi-solvent-based) for paper bags, corrugated boxes, semi-coated cardboard, Tyvek, PVC, and more.

- Chronplast S and Chronplast W (Solvent-based) for metals, PET, PE, glossy coated paper, glass, and flexible food packaging.

- Chronplast Elite (Solvent-based) for general materials, glass, and flexible food packaging.

- Dynaplast (Solvent-based) for flexible food packaging.

- eUrex (Solvent-based) for PVC, PP, PET, ABS, metal, glass, and treated polyethylene film.

- Hyprox (Solvent-based, UVS) for PE, PP, metal, and PETG.

- Ultraflex (Solvent-based) for BOPP, HDPE, PE, PVC, PP, PET, ABS, and polystyrene.

These inks are engineered for optimal adhesion, offering fast to super-fast drying times and long-lasting results on both porous and non-porous materials.

Identify trends, peak hours, and bottlenecks of your production line to maximize uptime and reduce downtime.

- Optimized resource allocation on peak hours and plan maintenance on off-peak hours

- Eliminates unexpected downtime by planning ink cartridge replacement

- Sets realistic production targets based on monthly production report

- Empowers production manager to make informed choices that enhance their process

Built for Demanding Environments:

From high-speed lines to batch-wise production, Hx Nitro adapts to your daily operational demands — delivering reliable performance across multiple shifts, packaging types, and environments.

Whether you’re coding cartons at 60 products per minute or marking foil lids at high speed, this printer delivers zero-error prints with minimum supervision.

Why Choose MapleJet

With decades of global expertise and a growing presence across sectors, MapleJet offers more than just hardware. You get a strategic partner invested in your long-term success, offering expert support, smart updates, and easy scalability.

Upgrade your batch coding, without upgrading your stress.

Get in touch today to schedule a product demo, receive a custom quote, or discuss ink options for your packaging line.

What Our Customers Say About Us!

FAQ's

Yes, it prints any types of high-resolution 2D barcodes, GS1 DataMatrix, Logos and etx..

Yes, it has Wi-Fi capability and it can be controlled using any smart device via Hx Manager software, requiring no intensive technical training.

Fast-drying solvent-based and water-based inks suitable for various materials and high-speed production.

Use the contact us form on the page https://maplejet.com/in/contact-us-page/ or email sales@maplejet-india.com

The Hx Nitro is designed to print on both porous and non-porous substrates, including cardboard, cartons, paperboards, glass, plastic, metal, flexible packaging, and glossy boxes.

It can print alphanumeric text, production and expiration dates, lot numbers, counters, 2D barcodes, GS1 DataMatrix, shift codes, logos, and external data.

The Hx Nitro supports print speeds up to 240 meters per minute (787.4 feet per minute) at 80 DPI.

The printer features built-in Wi-Fi, allowing for wireless control and monitoring via smart devices such as smartphones, tablets, or computers. The Hx Manager software provides real-time monitoring and message editing capabilities.

The controller is compact and lightweight, weighing approximately 750 grams with dimensions of 146mm x 84mm x 60mm, making it one of the lightest industrial TIJ printers.

The printer is compatible with MapleJet’s Solvent-based and Water-based Ink Cartridges including Boxtron inks (available in black, blue, and red) for porous surfaces and Chronplast-S solvent-based inks for non-porous surfaces like metal, PET, PE, and glossy or coated paper.

© 2026 MapleJet India.

- Home

- Products

- Industries

- Applications

- Resources

- About Us

- Contact Us

Founded in 2007 in Toronto, Canada, MapleJet’s Business philosophy is based on finding the perfect balance between quality, simplicity and low cost of ownership.

Head Office

4 Vata Court, Unit 20, Aurora

ON L4G 4B6,

Canada

T: (833) 387-7490