Whether You’re New to Coding & Marking or

Looking for Advanced Solutions,

MapleJet Got You Covered!

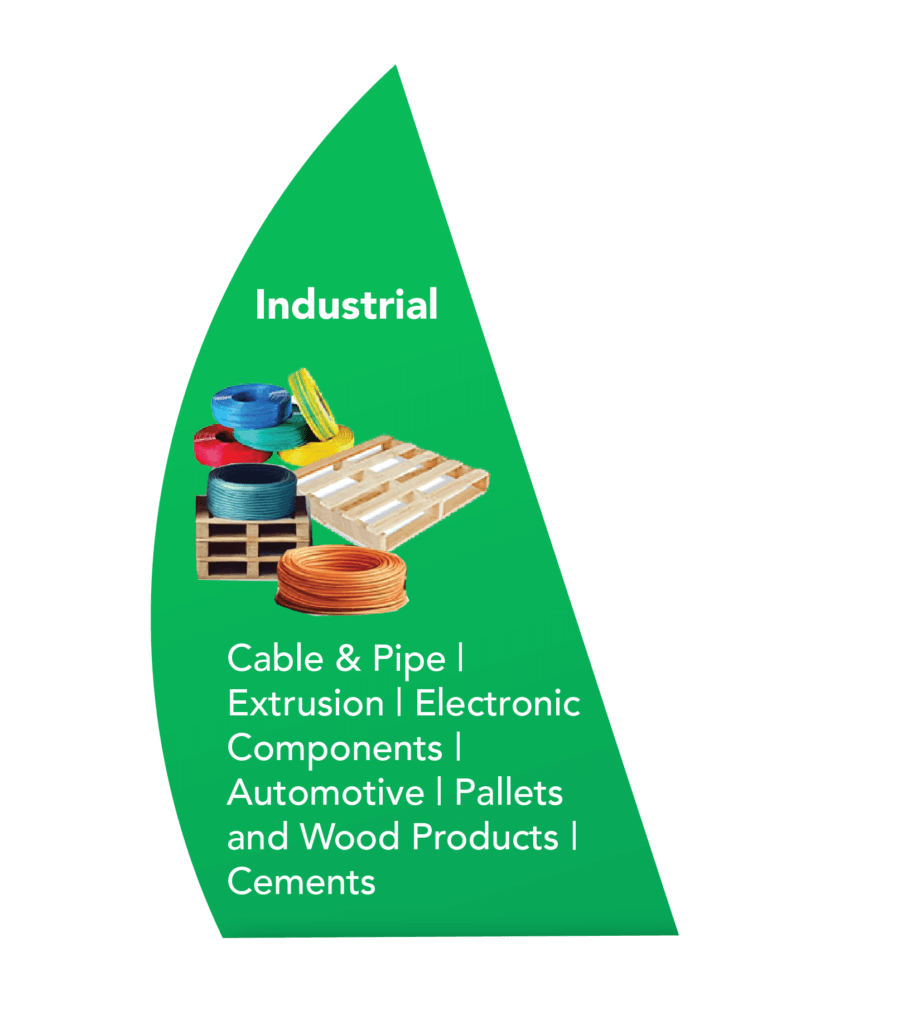

Tailored Coding and Marking Solutions for Every Business

MapleJet coding and marking technology offers convenience and flexibility to

ensure our coding solution matches your needs, from small, medium-scale to large-scale manufacturing companies.

Our Featured Products

High-Performance Inks for All Materials:

Fast Drying, Leak-Free, Low VOC

-

Hx Nitro Boxtron Red Ink Cartridge

₹4,536.00 -

Hx Nitro Boxtron Blue Ink Cartridge

₹4,536.00 -

Hx Nitro UltraFlex Ink Cartridge

₹7,140.00 -

Hx Nitro ChronPlast-W Ink Cartridge

₹7,560.00 -

Hx Nitro ChronPlast-S Ink Cartridge

₹7,140.00 -

Hx Nitro Boxtron Ink Cartridge

₹4,536.00

Trusted Reliability and Exceptional Service Across North America

RELIABLE PERFORMANCE

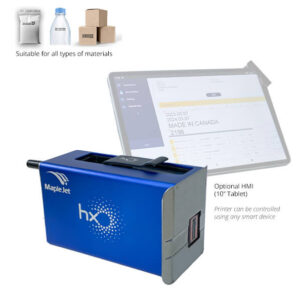

Built with Industry 4.0 capabilities, MapleJet

batch coding printers seamlessly integrate into any

smart manufacturing environment, offering

advanced technology and reliable

performance. Our printers are designed with

precision and durability in mind to meet the highest

industry standards.

EXCEPTIONAL SUPPORT

We pride ourselves on offering 24/7

world-class customer service and

support. Our dedicated team is

always ready to assist you in any

the situation, ensuring minimal

downtime and seamless printing

operations.

What Our Customers Say About Us!

FAQs

What is the advantage of using MapleJet TIJ compared to other TIJ printers?

MapleJet TIJ printers stand out from other TIJ printers with its cloud connectivity and Hx Manager, a unified platform accessible via any smart device (iOS, Android, Windows, etc.) that seamlessly connects the entire Hx printers, including both primary and secondary coding printers. The Hx Manager platform offers unified control over all printers, while integration with MapleJet-cloud boosts production efficiency through real-time data access. Additionally, the field software upgrade feature of the printer extends the hardware lifecycle, protecting customers’ investments and keeping the printers up-to-date.

Can I set up the printer by myself?

Installing the printer on most applications is straightforward. A pool of online videos is available to guide the user in setting it up on the production line. In some applications that require integration with third-party devices, MapleJet Technical will be able to guide the user via online support or a one-time visit.

Do I need a technician to operate the printer?

Using the printer is straightforward, once installed in the production line the printer is accessible using any smart device (iOS, Android, Windows, etc.).