Optimizing Flexible Packaging Lines Are you searching for a reliable Hx TIJ Printer today? First, modern flexible packing makes it the absolute top choice globally. However, printing on soft films…

Hx Nitro Printer for Food Manufacturing Applications

The Hx Nitro printer is designed to deliver exceptional performance in the food manufacturing industry. Its flexibility allows seamless integration with a wide range of food production lines, including form-fill-seal machines, pouch packaging, and other applications. With a versatile range of inks, the Hx Nitro ensures high-quality, durable codes and labels on all types of substrates, helping manufacturers maintain compliance and product traceability.👉 Click Hx Nitro printer specifications to explore features and additional details.

The Growing Packaged Food Industry and Emerging Trends

The packaged food industry is rapidly expanding as consumers become more conscious of nutrition, diet, and healthy food choices. Today’s buyers are shifting toward trusted and healthy packaged food options that align with their lifestyle and wellness goals. To meet this rising demand, food manufacturing companies are embracing health-oriented packaging solutions and adopting personalized product packaging that builds trust and enhances consumer experience. This transformation highlights how innovative food packaging trends are reshaping the future of the packaged food market.

In the food industry, coding and marking inkjet printers play a vital role in ensuring food safety, compliance, and proper packaging. Accurate date codes, batch numbers, and product details on packaging materials are essential for consumer protection and brand trust. To achieve this, manufacturers need industrial inkjet printers that deliver consistent, reliable, and high-quality printing across different substrates.

With over a decade of expertise, MapleJet offers advanced food industry coding and marking solutions through its Hx Nitro TIJ printer and Hx Ultro bulk ink TIJ printer. These printers are designed to meet the demands of food packaging printing by providing smooth, efficient, and long-lasting coding operations. Trusted by manufacturers in Canada, the United States, and worldwide, MapleJet printers ensure:

High-quality, durable prints for product packaging

Low to zero maintenance for uninterrupted production

Excellent ink performance on multiple substrates

Minimal downtime for maximum efficiency

From form-fill-seal machines to pouch packaging, MapleJet’s industrial TIJ coding printers guarantee long-lasting, high-quality date codes and labels that remain clear until products reach the consumer.

Optimizing Flexible Packaging Lines Are you searching for a reliable Hx TIJ Printer today? First, modern flexible packing makes it the absolute top choice globally. However, printing on soft films…

Flexible packaging lines demand high-performance coding solutions that can keep up with speed, maintain adhesion on non-porous materials, and minimize running costs. In production lines such as roll-to-roll (winder-rewinder), Horizontal…

Beating Hot Summer Production Demands When summer arrives quickly, massive factory production naturally ramps up. Specifically, industries like ice cream and bottled water face massive seasonal spikes. Consequently, these rapid…

As the printing industry evolves, there’s a growing focus on sustainable, eco-friendly solutions that reduce environmental impact without compromising on performance. Water-based inks have emerged as a leading choice for…

In the competitive and ever-evolving world of food manufacturing, ensuring that your products are accurately marked and comply with industry standards is more important than ever. The right inkjet marking…

Ensuring the safety of our food from farm to fork involves a complex chain of events, from harvesting raw materials to packaging and distribution. At every step, coding and marking…

In North America, the secondary packaging market has seen a lot of growth, driven by the growing demands of industries such as food and beverage, pharmaceuticals, and consumer goods. As…

In the food industry, particularly for the sweet and snack packaging line, the ability to efficiently and accurately print codes and markings on the packaging is essential for product…

MapleJet is a Canadian-based company offering industrial inkjet printing solutions for coding and marking on packaging across food, beverage, pharmaceutical, and other industries.

They offer TIJ (Thermal Inkjet) printers like Hx Nitro and Hx Ultro, designed for high-quality, low-maintenance coding on various packaging materials.

Hx Nitro is designed for food packaging applications such as form-fill-seal pouches, jars, cartons, and trays. It’s compact, reliable, and compatible with fast-drying inks.

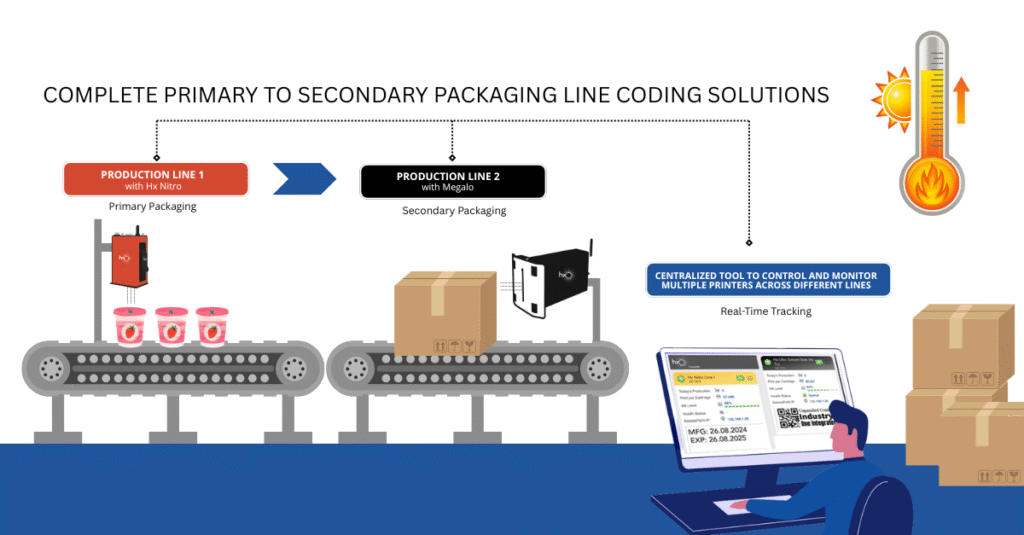

Yes. Hx Nitro handles primary packaging, while Hx Cartro or Megalo printers are used for secondary packaging like cartons and corrugated boxes.

Thermal Inkjet (TIJ) is a contactless printing method using heat to spray ink, ideal for clean, high-resolution coding on packaging.

They are easily integrated into conveyors and form/fill/seal machines, with options for both inline and offline coding.

Yes. They are designed to keep up with fast-paced lines with minimal downtime and consistent code quality.

Yes. The systems are engineered for reliable performance even in demanding conditions like summer beverage or ice cream production.

MapleJet offers fast-drying, high-adhesion inks, including eco-friendly water-based options and bulk ink systems for cost-efficiency.

It’s a TIJ printer optimized for flexible packaging with bulk ink cartridges, reducing costs and increasing runtime.