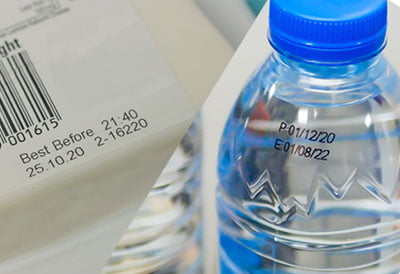

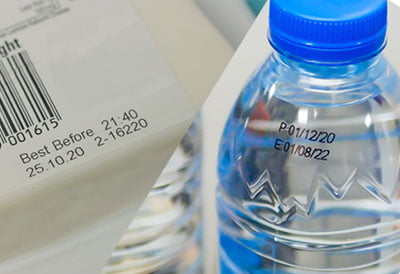

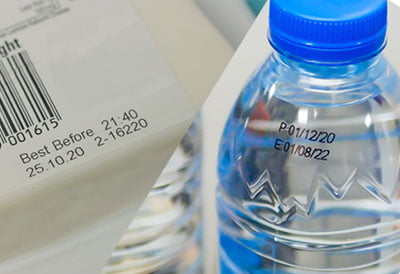

PET bottles are one of the largest categories of beverage packaging used in this industry. Coding and marking on PET bottles creates a set of challenges unique to this industry that limits many manufacturers’ choices when it comes to choosing the best printers. Some factors to be considered are humidity and how moist the atmosphere of the working environment is, downtime due to maintenance and ink change, cost of ownership, and overall ease of operation of the coding and marking printer.

MapleJet technology offers printers that have been tested in this market for years and have proven effective for coding and marking on PET bottles. Our printers are low maintenance and have a low cost of ownership as well as minimal training is required for the operators. The small size and durable design of our printers allow for easy setup and are capable of being moved to different locations performing with the highest of efficiencies at a minimum time.

Additionally, our inks offer superior adhesion on many materials while maintaining maximum print quality on any part of the bottle including the neck, shoulder, or bottom.

Printing on PET Bottles

Maplejet’s Hx Nitro industrial inkjet printer offers the easiest and simplest way to print text, production date, lot number, counter, 2D Barcode, GS1 DataMatrix, Shift, Logo, and External Data to any porous or non-porous substrate.

See More

When it comes to food manufacturing, an adage that says “time is money” holds its true meaning, particularly when demands in the food supply are at a peak. Therefore, production…

While plastic packaging is widely used in all industries, the beverage manufacturing industry has adopted plastic packaging the most. 1According to a study made by Statista on the global packaging…

MapleJet is a leading brand and supplier of high-quality coding & marking inkjet printers from Canada. These printers are used in a wide variety of industry sectors including food, beverage, pharmaceutical or personal care, and building materials.