Home » Ultro Continuous Thermal Inkjet Printer

Hx Ultro CTIJ Printer

Hx Ultro CTIJ Printer

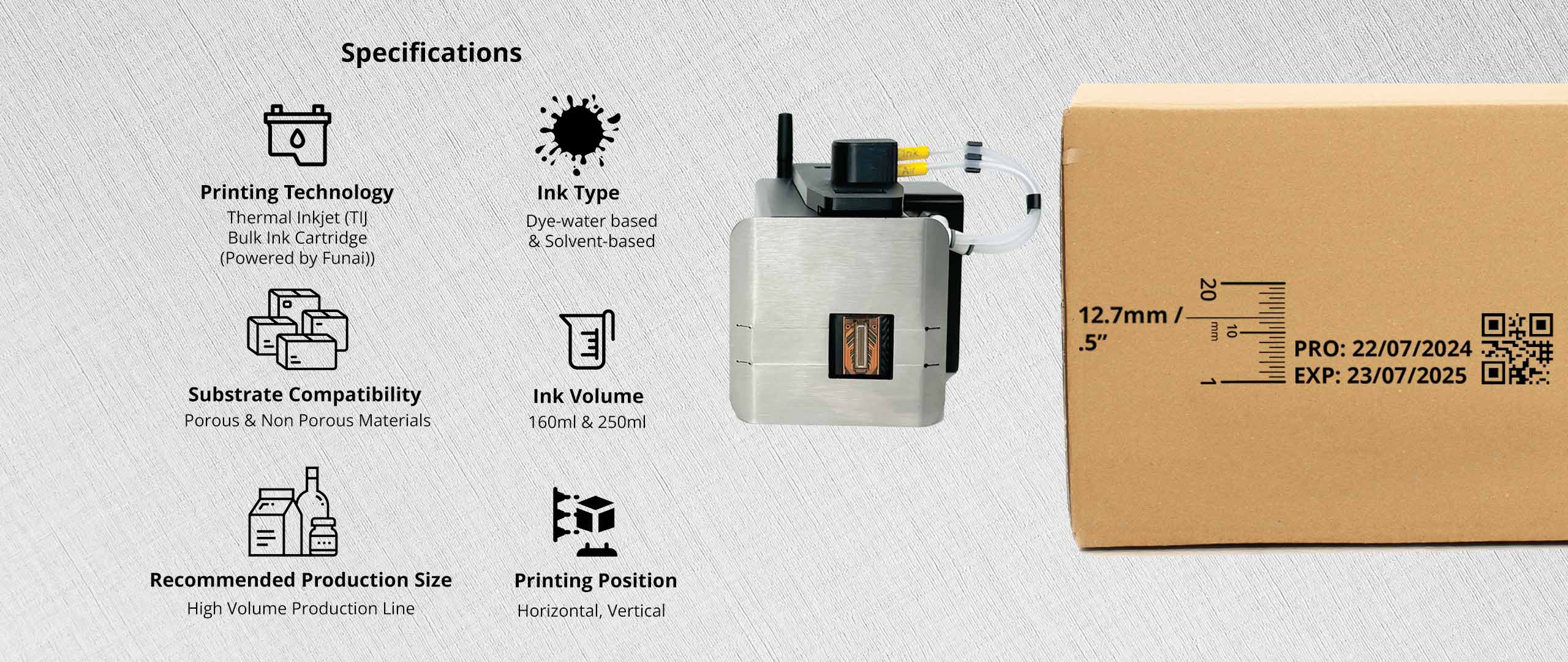

Hx Ultro CTIJ Printer designed to lower operational costs, particularly for high-volume production lines. In addition, the bulk ink supply, which comes in different volume, minimizes operator interventions due to reduced cartridge replacement needed for uninterrupted printing.

Hx Ultro comes in two models. Hx Ultro-HT offers high throw distance printing from the product’s substrate of up to 10mm perfect for coding and marking on recessed, sloped, or angled surfaces. Hx Ultro-HR enables high-resolution printing of date codes, machine-readable and scannable 2D Barcodes similar to TTO prints.

As part of the Hx family of printers, it takes advantage of Hx Manager features for efficient and smooth production line operations; Advanced Printer Health Check, Economy Mode Printing, Daily Production Report, Field Upgrade Facility,

and more!

Why Choose Hx Ultro Continuous Thermal Inkjet Printer?

1.) Hassle-Free Operation: The Hx Ultro features an easy-to-replace cartridge design, eliminating the need for maintenance. Simply swap the cartridge in case of any issues, ensuring consistent, high-quality performance with no mess or downtime.

2.) Versatile Compatibility: Suitable for a wide range of materials and substrates, the Hx Ultro delivers high-quality prints on various surfaces

3.) High-Resolution 2D Barcodes: Effortlessly print crisp, high-resolution 2D barcodes that meet even the most demanding industry standards.

4.) User-Friendly Software: With Hx Manager, operators can manage all printing tasks with ease. It is accessible from any smart device, offering simple and intuitive control.

5.) Seamless System Integration: As part of the Maplejet Hx Printers family, the Hx Ultro integrates effortlessly into an existing systems, providing reliable and efficient printing solutions for production line needs.

6) Consistent High-Resolution Codes: Achieve up to 600 dpi print resolution for machine-readable and mobile-scannable 2D barcodes.

7) No Skilled Labor Required: Simple maintenance without the need for factory visits from engineers, unlike CIJ systems.

8) In-house Troubleshooting & Remote Support: Access free online materials and receive remote technical support as needed.

9) Compact Design: The printer’s small footprint allows for easy integration into any packaging line without bulky components.

10) Low Cost of Ownership: The Hx Ultro CTIJ offers four times the ink volume of regular TIJ, resulting in lower per-print costs and overall ownership expenses.

11) User-Friendly CTIJ Technology: The ink cassette design allows for easy changeovers and includes an authentication tag system for accurate usage tracking.

12) Advanced Smart Features: With Wi-Fi capability, operators can design

messages and monitor the printer remotely, ensuring uninterrupted printing during

long runs.

Hx Ultro merges Cost Efficiency, Reliability, Simplicity, and Sophistication into one technology!

Read the white paper on “The Evolution of Product Coding” and understand why Hx Ultro becomes a viable solution for most new primary packaging applications.

Hx Ultro Solvent CTIJ provides continuous printing of high-quality date codes, especially for high-volume production lines.

CTIJ printing technology is revolutionizing the coding process on flexible packaging lines, including Vertical Form Fill Seal (VFFS), Horizontal Form Fill Seal (HFFS), and winder-rewinders.

-

ADVANCED FEATURES

-

MESSAGE DESIGN

-

INK TYPES

-

HX ULTRO PRINTER BROCHURE

MapleJet Cloud Integration:

- Real-Time Monitoring & Management: Access real-time production data, printer status, performance history, and downtime reports. Design messages and control printers remotely.

Hx Console:

- Printer Health Check: Monitor printer status with real-time warnings and suggested remedies for quick issue resolution.

- Economy Mode: Reduce ink consumption by 50%, increasing print output per cartridge and lowering costs.

- Field Upgrade: Enable future software upgrades, extending the printer’s lifecycle beyond industry standards.

- Auto Notify: Events such as ‘low ink level’, ‘printing completed’, and’online data received’ can be automatically communicated by choosing selected channels e.g. USB, RS232, and Wi Fi (HTTP)

- Auto Pilot: Allows other external device to control and monitor Hx Printer. Any third party device (e.g. PLC), system, or software can send a command to Hx Printer.

- Daily Production Report: Provides an hourly print report of the printer giving an overview of the complete daily production

- External Data: Easy integration to external devices e.g. PLC, weighing scale, etc for printing variable data. Auto calculation and printing of the product weight

- Ink Estimation Calculator: Provides an estimate number of prints per cartridge based on the message and other parameters.

Simple Message Editor:

- User-Friendly Interface: Offers a clean, intuitive interface designed for effortless navigation, enabling operators to create and modify messages quickly.

- Text Design: Create customized text for product labeling, batch codes, or other critical information, with options for various fonts, sizes, styles, and alignments.

- Production and Expiration Dates: Automatically generate production and expiration dates with customizable formats to meet regional and industry-specific compliance.

- Print Settings Control: Configure essential print settings, such as print speed, resolution, and direction, to ensure optimal print quality and efficiency for different substrates and production environments.

- Message Management: Save frequently used messages for easy retrieval, editing, and reuse, reducing setup times and improving production line efficiency.

- Encoder Parameters Activation: Seamlessly activate and configure encoder settings to synchronize printing with variable line speeds, ensuring consistent print quality regardless of production speed changes.

External Data Integration for Real-Time Printing:

- Dynamic Data Fields: Design messages that incorporate external data sources, such as product databases to print dynamic and real-time information, including serial numbers, batch codes, and more.

- Seamless Connectivity: Connect the printer directly to external data sources, enabling real-time data retrieval for on-the-fly printing without manual input or delays.

- Versatile Data Formats: Support for various data formats (CSV, XML, SQL, etc.) allows integration with a wide range of data management systems, enhancing flexibility and adaptability to different production environments.

MapleJet offers a versatile range of high-performance inks for the Hx Nitro TIJ printer, catering to various substrate needs including plastic, steel, aluminum, glass, metal, and wax-coated surfaces. Our ink lineup includes:

- Aspro (Solvent-based, white pigment) for general material applications on porous and non-porous surfaces.

- Boxtron SSD and Boxtron SSP (Semi-solvent-based) for paper bags, corrugated boxes, semi-coated cardboard, Tyvek, PVC, and more.

- Chronplast S and Chronplast W (Solvent-based) for metals, PET, PE, glossy coated paper, glass, and flexible food packaging.

- Chronplast Elite (Solvent-based) for general materials, glass, and flexible food packaging.

- Dynaplast (Solvent-based) for flexible food packaging.

- eUrex (Solvent-based) for PVC, PP, PET, ABS, metal, glass, and treated polyethylene film.

- Hyprox (Solvent-based, UVS) for PE, PP, metal, and PETG.

- Ultraflex (Solvent-based) for BOPP, HDPE, PE, PVC, PP, PET, ABS, and polystyrene.

These inks are engineered for optimal adhesion, offering fast to super-fast drying times and long-lasting results on both porous and non-porous materials.

Identify trends, peak hours, and bottlenecks of your production line to maximize uptime and reduce downtime.

- Optimized resource allocation on peak hours and plan maintenance on off-peak hours

- Eliminates unexpected downtime by planning ink cartridge replacement

- Sets realistic production targets based on monthly production report

- Empowers production manager to make informed choices that enhance their process

What Our Customers Say About Us!

© 2026 MapleJet India.

- Home

- Products

- Industries

- Applications

- Resources

- About Us

- Contact Us

Founded in 2007 in Toronto, Canada, MapleJet’s Business philosophy is based on finding the perfect balance between quality, simplicity and low cost of ownership.

Head Office

4 Vata Court, Unit 20, Aurora

ON L4G 4B6,

Canada

T: (833) 387-7490