ProDigit Bi-color Carton Printer is a fast-high resolution general purpose inkjet coding printer

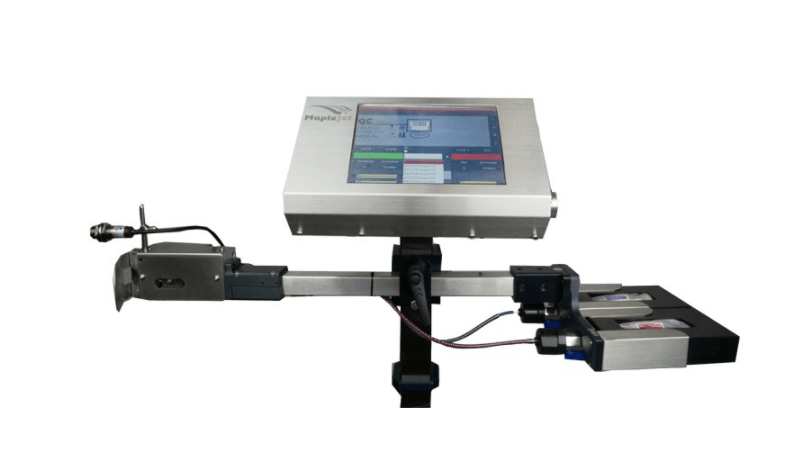

MapleJet ProDigit Bi-color Carton coding and marking printer have an industrial ability to print two colors simultaneously onto a substrate providing perfect two-color coding solutions in the industry. The Bi-color oil-based printer uses a dual-cartridge based ink system with choices of Red, Black, White & Blue to print on porous substrates. Its modular design enables it to use two separate print engines using one controller; thus, adding more ability to print either on two sides of the corrugated box or extending its printing height.

Do Away with Mundane Single Color Printing

Bi-color inkjet coding and marking printers are not only low-cost of ownership but also economically friendly for companies looking to save cost while branding directly on the product. It prints high-resolution logos, pictograms, text, and other important information in two colors. using a single print engine. This ability helps product manufacturers boost up their company branding and step ahead of their competitors in the industry.

Sustainable & Eco-friendly Printing

Maplejet ProDigit uses a long-lasting printhead powered by Xaar Printhead Technology. ProDigits printhead lasts for an average of two years even on continuous production. This promotes good environmental practice in avoiding disposal of toxic waste materials drawn by waste ink and plastic into the environment.

Drop on demand High-resolution Inkjet Coding Printer

Maplejet ProDigit inkjet coding machine uses piezoelectric drop-on-demand (DOD) printing technology. The printhead produces a precise amount of drops onto the material resulting in high-resolution print in almost all types of substrates compared to other DOD inkjet coding printers such as valve jet and thermal inkjet printers.

Save Cost While Printing

ProDigit inkjet coding printer offers a low cost of ownership with its simple yet industrial strength functionalities. Using durable long-lasting printheads that can save cost compared to disposable printheads of thermal inkjet printers. ProDigit printers are operator-friendly and require low maintenance to continuously produce superior print quality throughout the production.

Reduce Corrugated Box Inventory

Massive and continuous production lines demand a wider inventory and warehouse space. The volume of production and the limited available space for storage often creates problems and confusion especially in the time of dispatching the product to the rightful receiver, resulting in huge sales blunder. With Bi-color corrugated printer, it eases the inventory stress by printing directly onto the secondary packaging using the second color as an obvious marking to sort the product.

How inkjet coding printer it works…

There are two kinds of inkjet coding printing technology – Continuous Inkjet (CIJ) Printing and Drop-on-Demand (DOD) inkjet printing. Maplejet ProDigit works with DOD through Xaar Printhead Technology.

Under DOD falls three classes; valve jet – the flow of intermittent ink droplets are controlled by a valve; thermal inkjet – the use of a tiny heating element to force the ink out of the nozzle; and piezoelectric – a charge is generated when force is applied unto a certain material producing precise amount of droplets required for printing. Maplejet ProDigit inkjet coding printer uses piezo inkjet technology.

Piezoelectric DOD printing uses piezoelectric technology as actuators for drop ejection. The ink vibration at the nozzle openings is precisely controlled by the actuator once it receives the signal resulting in a multi-sized droplet ejection; thus, delivering outstanding print quality to a range of different substrates.

Pro Digit Bi-Color Corrugated carton printer

A full feature coding printer machine with two-color printing. Using oil-based ink perfect for printing on corrugated boxes, the bi-color corrugated carton printer is designed to create lasting prints and cost-effective production. While printing directly unto corrugated boxes, companies can also take advantage of its high-resolution two-color printing for their company branding. The system is suited for printing logos and graphics in various industries. It is tailored for those who are seeking a colorful design that will stand out among the products in the market.

Click here for a video to check out how printing is done on corrugated carton boxes with a bi-color corrugated carton printer.

Specifications

- KEY BENEFITS

- CONTROLLER SPECIFICATIONS

- PRINTING FEATURES

- PHYSICAL SPECIFICATION

- ADDITIONAL INFORMATION

- OPTIONS

- Two color printing on porous or pvc pipe materials

- Can operate single or double printheads using one controller

- Easy and simple to use and no extensive training required

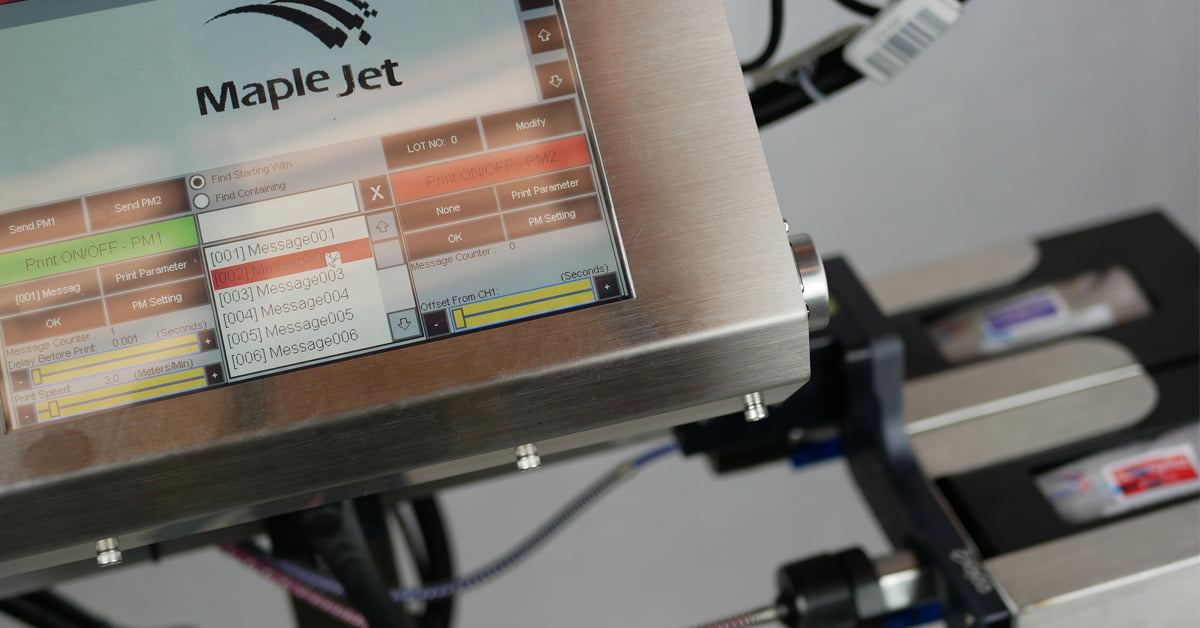

- User-friendly display interface

- Design, print and store message capability

- Up to 8 number of lines with maximum speed of 40M/min

- Remote & field upgradeable with modular components and options

- Compatible on oil-based for porous surfaces or solvent-based for non-porous surfaces

- Compact with industrial strength infrastructure

- Display Screen: 8.4″ Color TFT LCD with Industrial Touchscreen

- Printing Channels: 2 Channels with Separate Messages

- Print Module Connection: Expandable up to 6 heads

- Connectivity: Computer, PLC, Weighing device, Barcode reader

- Connection ports: Ethernet and RS232

- External Database Print Capacity: More than 1 Million records

- Menu Language: All Languages available on request

- Message Saving Capacity: Up to 999 Messages

- Password Protection: Yes

- Input Voltage: 90-240 VAC

- Power: 60 W

- System Diagnostic: Yes

- Environmental Conditions: 0-50 degrees Celsius – Humidity 0-80% RH

- Start & Stop Time: Immediate

- Standard: CE, CSA & UL

- Resolution: 180 dpi

- Max Print Speed: 40M/minutes

- Max No. of Lines: 8

- Height Range of Printable Characters: 2-18mm

- Printable Language: All available on request

- Number of Fonts: Six preloaded fonts (user defined)

- Logo Printing Option: Yes

- Message Component: Text, Date, Time, Logo, Counter, Shift, Barcode, External Data, Lot Number,Basic Shapes

- Auto Update: Production & Expiry date, Time, Shift, External Data

- Barcode: All major barcodes supported (1D, 2D & GS1)

- Print Module Angle Adjustment: 0-180 degrees

- Ink Consumption Control System: Yes

- Counter: Various counter option

- Body Material: Stainless Steel

- Wight with Stand: 21 kg

- Controller Dimension: 300 x 192 x 60 mm

- Standard Software Option: Flexicode Message Design Software, Remote Manager Data Management Software

- Connectivity with Third Party Software: Yes

- Ink Supply System: Standard Cartridge Based System (180ml)

- Ink Types: Solvent-based (Pipe), Oil-based (Porous Materials)

- Ink Colour Options: Black, White, Red, Blue, Yellow

- Ink Supply System: Hybrid Ink System (Auto Priming) + Heater & Agitation System

- Printhead Configuration: Square Type Printhead (with Pneumatic System for Pipe Marker)

- Encoder: Yes

- Extender System: Enables Connectivity up to six print module

- Low Level Warning Ink System: Yes \Support Options: Stainless Steel Stand, Aluminium Stand, Elevator, T-bracket

- Conveyor: Various sizes and designs available on request