Horizontal Form-Fill-Seal (HFFS) machines are a vital part of modern packaging for small to medium-sized enterprises (SMEs). Whether producing snack pouches, cosmetic sachets, or single-use supplements, HFFS lines help SMEs deliver products quickly and efficiently in flexible packaging.

However, when it comes to coding and marking, many SMEs encounter significant challenges that hinder production, increase costs, or compromise print quality.

The Hx Nitro Thermal Inkjet (TIJ) Printer is purpose-built to solve these challenges—bringing clean, intelligent, and low-maintenance coding to even the most space-constrained HFFS setups.

Common HFFS Applications in SMEs

HFFS packaging lines are popular among SMEs in industries like:

- ✅ Food & Snacks – Chips, cookies, nuts, powders

- ✅ Health & Wellness – Protein sachets, vitamins, nutraceuticals

- ✅ Cosmetics & Skincare – Cream samples, single-use gels

- ✅ Pet Care – Treat pouches and nutritional supplements

- ✅ Pharmaceutical – Blister-compatible sachets and single-dose packs

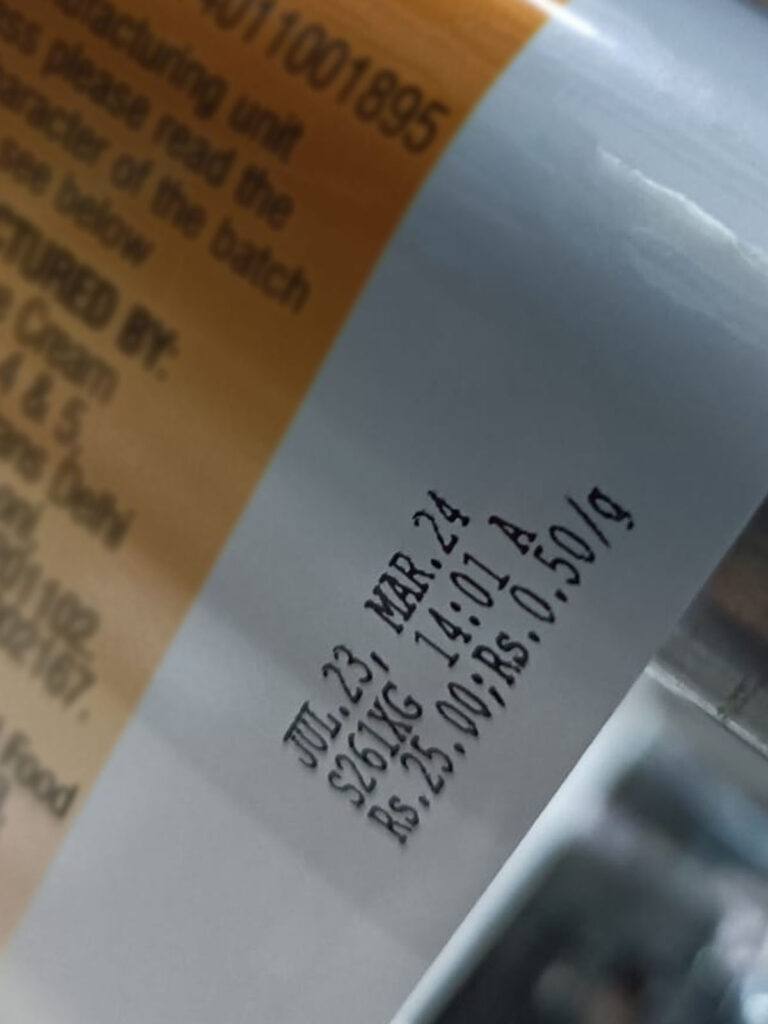

All these applications require high-resolution, reliable printing of variable data, like:

- Expiry dates

- Batch/lot numbers

- Production times

- Regulatory codes

- Barcodes or QR codes

The Real Challenges SMEs Face in Coding on HFFS Machines

While HFFS offers efficient packaging, integrating printing solutions into these systems can create major pain points for SMEs:

1. Limited Installation Space

Most HFFS machines are compact, leaving little room for bulky or complex coding equipment.

2. High Maintenance & Consumable Costs

CIJ printers require frequent servicing, cleaning, and handling of messy fluids. TTO printers use costly ribbons that frequently jam or tear.

3. Frequent Product Changeovers

SMEs often produce many SKUs on a single line, which requires fast and error-free switching between print messages and formats.

4. Difficult Flexible Packaging Surfaces

Laminated films and glossy pouches make it hard for ink to adhere without smudging, especially at high line speeds.

5. Lack of Skilled Technical Support

Many SMEs don’t have in-house engineers or technicians to maintain complex coding equipment or troubleshoot print issues.

Why the Hx Nitro TIJ Printer Solves These HFFS Coding Challenges

The Hx Nitro is a compact, cartridge-based printer designed to eliminate all the friction points SMEs encounter on HFFS lines.

✔ Compact, Flexible Mounting

- Small printhead fits into tight HFFS configurations—near sealing jaws or film feeds

- Installs quickly with minimal mechanical changes

✔ Zero Maintenance, Mess-Free

- Cartridge-based TIJ system = no cleaning, no fluids, no downtime

- Swap cartridges in seconds without tools

✔ Easy Message Control via Smart Devices

- Use Hx Manager on a phone, tablet, or PC to:

- Change messages on the fly

- Manage multiple SKUs

- Set variable fields like time, date, batch code

✔ Reliable Printing on Films and Laminates

- Compatible with solvent-based inks that adhere well to non-porous surfaces

- Fast-drying to avoid smearing at high sealing speeds

- Print 600 dpi resolution logos, QR codes, and sharp text

✔ Built for Growing SMEs

- Affordable investment with a low total cost of ownership

- No technician required to operate or maintain

- Upgradeable to centralized control via Hx Console as production scales

Hx Nitro In Action

Typical Equipment vs. Hx Nitro Comparison

| Coding Method | Common Issues | Hx Nitro Advantage |

| TTO Printer | Ribbon breakage, alignment issues, and expensive | No ribbons, compact, no consumables beyond ink |

| CIJ Printer | Complex setup, solvent handling, maintenance | Clean cartridge system, no need for a technician |

| Manual Labeling | Labor-intensive, prone to human error | Automated inline printing with full message control |

| Pre-printed Films | High MOQs, inflexible to changes | On-demand coding directly on flexible packaging |

Interlocking: Built-In Safety for Error-Free Packaging

A key advantage of using the Hx Nitro on HFFS lines is its ability to interlock with the packaging machine. This feature ensures that no product moves forward unless coding is completed—a critical requirement for SMEs focused on quality control and compliance.

How it works:

The Hx Nitro can be connected via Input/Output (I/O) ports to the HFFS machine. If an error occurs—like a depleted cartridge or missed print—the packaging machine will automatically stop, preventing unmarked products from being sealed and shipped.

✅ Key Benefits for SMEs:

- Avoid Uncoded Products: Ensures every sachet or pouch is properly marked.

- Minimize Waste: Prevents packaging material and product loss due to unnoticed printing errors.

- Enhance Compliance: Supports traceability and regulatory requirements with 100% coded output.

- Easy Integration: No need for advanced PLC programming—Hx Nitro connects easily to most HFFS lines.

Summary: Hx Nitro is Made for SMEs Running HFFS Lines

| SME Packaging Need | Hx Nitro Solution |

| Limited space | Ultra-compact printer |

| Multi-SKU flexibility | Smart message control via smart HMI |

| No time for maintenance | Maintenance-free, cartridge-based printing |

| Printing on glossy film | Fast-dry inks with excellent adhesion |

| Small budget | Affordable price + no recurring service costs |

Ready to Simplify Coding on Your HFFS Line

The Hx Nitro Thermal Inkjet Printer offers the perfect balance of print quality, ease of use, and cost-efficiency for SMEs looking to scale efficiently.

Make coding the easiest part of your packaging process—with Hx Nitro.

Recent Comments