If you are wondering why MapleJet decided to remove the ‘so-called’ industry-standard touchscreen display found in almost all thermal inkjet printers. You are in the right place. To give you a little bit of a heads up. It is not about trying to be unique in appearance among the other TIJ coding technologies in the market. The reason behind this is certainly more profound and well thought out. But yes, let us give uniqueness a bit of merit.

In this blog, let us dive into several reasons why MapleJet developed a TIJ printer sans the touchscreen display.

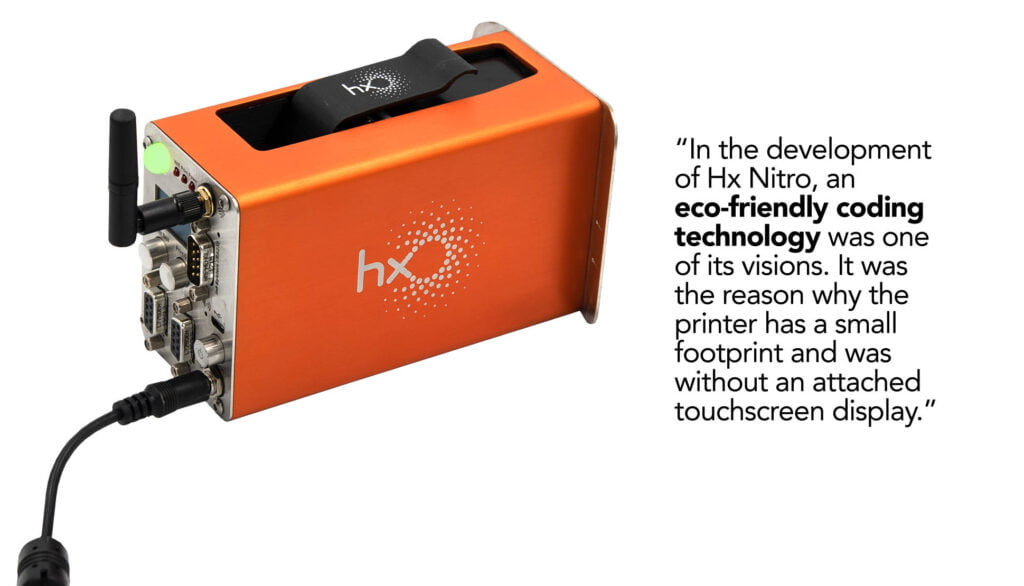

A more Eco-friendly TIJ Coding Printer

The world has an e-waste problem and everyone wants to help in solving it. MapleJet does, too. In the development of Hx Nitro, an eco-friendly coding technology was one of its visions. It was the reason why the printer has a small footprint and was without an attached touchscreen display. The smaller the design the fewer materials used, the fewer electronic parts integrated, and it is easier to dispose of after its service (shelf) life. This idea paved the way to developing a printer that is even more sophisticated and uses Wi-Fi that can communicate with other Wi-Fi-enabled devices such as computers, tablets, or smartphones.

Now, imagine a medium or large-size manufacturing company with 15 Hx Nitro printers running in the production line. Since Hx Nitro can be controlled with any Wi-Fi-enabled device, the operator can use a single computer or tablet to operate the 15 printers, remotely and simultaneously. There is even no need for the company to buy a new computer or tablet since any available office smart device will work. And then, imagine you have 15 other TIJ printers with a standard touchscreen display. The operator needs to be physically near each one of them to control, design messages, and operate these printers. That consumes a lot of operator time and effort. Most importantly, when the service life of these printers ends, the 15 printers with more electronic parts could create more e-wastes. And, we understand that e-wastes have a negative impact on the environment.

Thus, it is important for OEM to take into account the full life cycle of a machine from its development to disposal. How much impact will it have on the environment? A more responsible TIJ OEM does not only create technologies to cater to the needs of the manufacturing industry but also takes into consideration the effects of this technology on the environment. That is what MapleJet tries to exemplify by removing a part of the traditional TIJ setup – the touchscreen display. The lesser electronic part, the less e-waste to dispose of, and less harmful to the environment.

On the other hand, when it comes to environmental friendliness, some coding technologies claim that they are a notch ahead of TIJs. Thermal inkjet printers are cartridge-based and the volume of each cartridge is comparatively lower than other technology’s ink systems. Thus, using the printer continuously means increasing the number of ink cartridge disposal, which is relatively bad for the environment. However, this issue may be acceptable for continuous high-volume throughput production lines. In this light, the development of a new ink system is underway through MapleJet Research and Development team, in partnership with Funai and Kao Collins Inc. The bulk-ink system will soon provide manufacturers using TIJ with a better ink system option that is more environmentally friendly.

More Operator freedom

Most production lines have either two or more printers installed on their production floor. Using a single tablet or computer gives more freedom for operators to control all the printers remotely all at the same time. Operators do not have to travel from one printer to another to design a message, change the parameter, or just monitor the status of the printer. Everything can be done using that single smart device. This also gives operators more freedom to focus on other important aspects of the production line.

User-friendly TIJ Coding Technology

We all heard your complaints. It is not easy to use that touchscreen display because sometimes it’s hard and just doesn’t work properly. So we have to call for a technician’s help. What makes Hx Nitro more friendly without the touchscreen display is that the operator can use the smart device. It can be a smartphone or a tablet. Perhaps, everyone on the production floor owns one. So controlling the Hx Nitro printer is never really difficult.

Design Simplicity

Less is more! Have you heard of that before? That is the concept Hx Nitro has. With the small footprint coding printer that can do a lot of work. Hx Nitro’s physical design is small, lite but compact. And its simple design is made for industrial work. The printer is also loaded with various features that manufacturers can take advantage of. Click this link to read a few of them.

Take advantage of Wi-Fi connectivity

We already have mentioned why the WiFi for Hx Nitro was conceived. From using the wireless control device (touchscreen display), MapleJet takes advantage of wireless connection. When Hx Nitro is connected to a Wi-Fi Access Point, operators will also unravel several features that can help enhance coding and marking in their production line.

Recent Comments