Accurate and durable coding on cartons and cases—such as barcodes, batch numbers, expiry dates, and branding—is essential for downstream traceability, inventory control, and compliance with global supply chain standards.

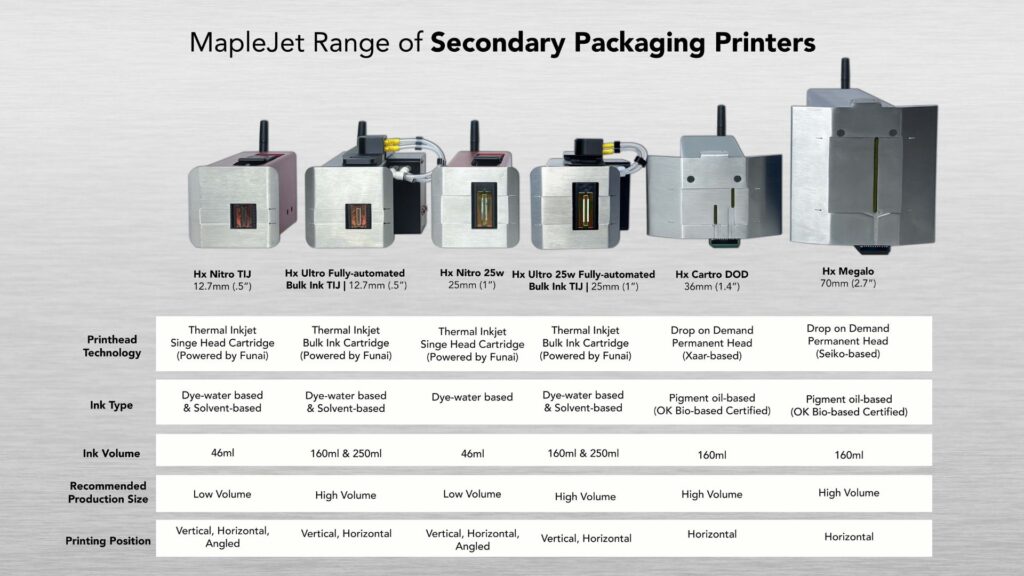

MapleJet delivers a specialized portfolio of industrial inkjet printers designed to meet the specific needs of secondary packaging. With cartridge-based and bulk ink options, print heights ranging from 12.7mm to 70mm, and integration capabilities aligned with Industry 4.0 standards, MapleJet printers are designed to scale with your operational demands—whether you’re running short batch productions or 24/7 high-volume logistics lines.

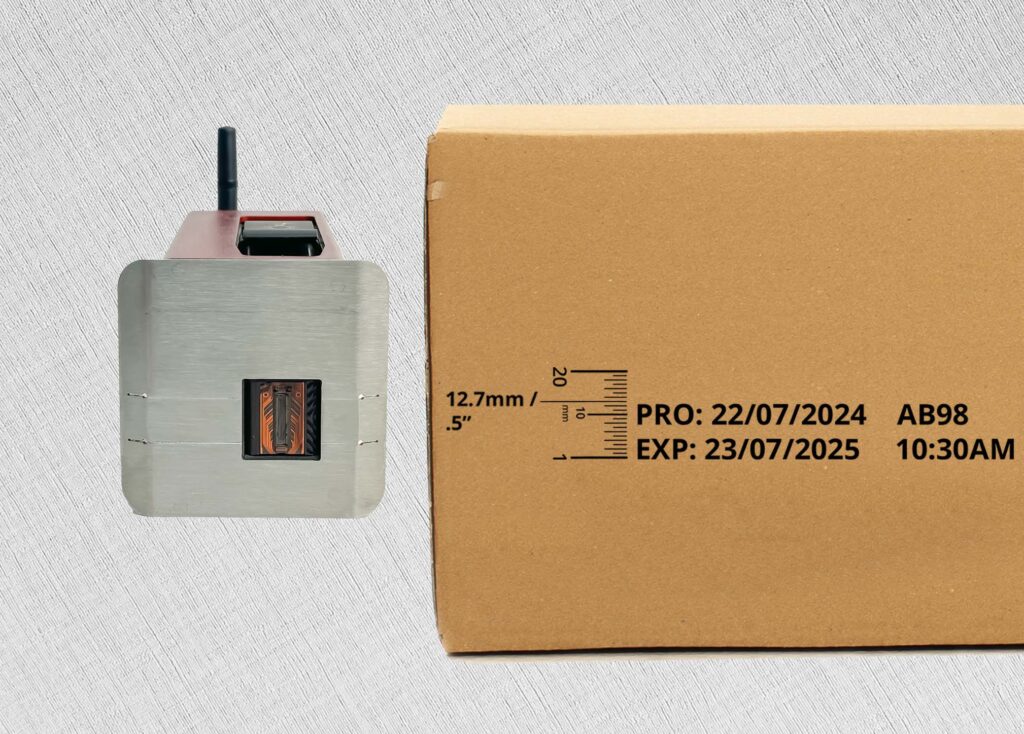

Hx Nitro – Compact Versatility for Light-Duty Coding

The Hx Nitro is a lightweight, cartridge-based TIJ printer engineered for reliability and ease of use in limited-space production environments. With up to 12.7mm print height and maintenance-free operation, it’s well-suited for small to mid-sized warehouses and packaging stations requiring precise, on-demand printing on porous materials like corrugated cartons.

Highlights:

- Compact footprint for flexible installation

- Water-based ink for high-resolution text and barcodes

- Ideal for low-volume or seasonal lines

- Controlled via smart devices using Hx Manager

Hx Nitro 25w – Bigger Print in a Small Package

For operations requiring larger text or expanded code fields, the Hx Nitro 25w offers 25mm print height in a compact, single-head configuration. Built on the same intuitive platform as the Nitro, it delivers excellent legibility for mid-sized secondary packaging needs.

Highlights:

- 25mm print height with a single Funai cartridge

- Maintenance-free, clean operation

- Excellent for outer case coding with minimal integration effort

- Remote monitoring via Hx Manager

Hx Ultro – Bulk Ink Performance for Demanding Operations

The Hx Ultro is designed for continuous, high-volume coding. Its bulk ink system minimizes interruptions while offering significantly lower cost per print, making it ideal for facilities operating around the clock. Paired with the unified Hx Manager platform, it enables quick message editing and system oversight.

Highlights:

- Bulk ink tank for extended run times perfect for high volume production line

- Ideal for secondary packaging in fast-moving industries

- Real-time print monitoring and message creation via Hx Manager

Hx Ultro 25w – High-Speed Printing with Extended Coverage

For operations needing a larger print area in high-volume production environment, the Hx Ultro 25w offers 25mm of print height with the benefits of bulk ink delivery. This is particularly useful for multilingual labeling, regulatory text, GS1 barcodes, and serialized barcoding where space and clarity are critical.

Highlights:

- 25mm print height with high-speed output

- Bulk ink tank reduces maintenance frequency

- Excellent for mid to large-scale packaging lines

- Integrated control via Hx Manager

Hx Cartro – Coding for Case-Level Clarity

The Hx Cartro brings large-character printing to carton coding lines, offering up to 36mm (1.4 inches) print height. It is designed for bold barcodes, large branding elements, and high-visibility messages, making it ideal for operations requiring compliance and visual identification across large warehouse networks.

Highlights:

- Large print for high-impact coding

- Rugged construction suited for industrial use

- Handles logos, GS1 barcodes, and text effortlessly

- Coupled with OK-biobased ink for eco-friendly coding

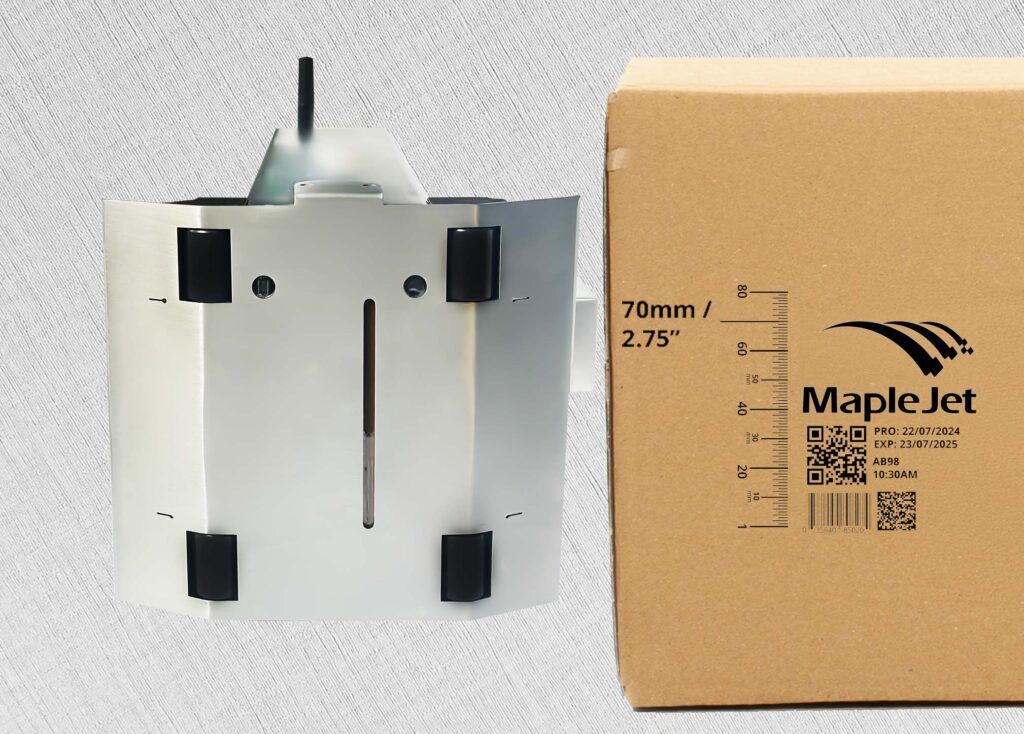

Hx Megalo – Large Character Coding for High Visibility

At the top of the range, the Hx Megalo provides 70mm print height with a single printhead—ideal for outer case coding, warehouse labeling, and branded secondary packaging. It features oil-based ink that is fade-resistant and durable, ensuring high readability even under variable storage and transport conditions.

Highlights:

- Fade-proof and heat-resistant printing

- Excellent for brand logos and large-format codes

- Designed for high-throughput logistics centers

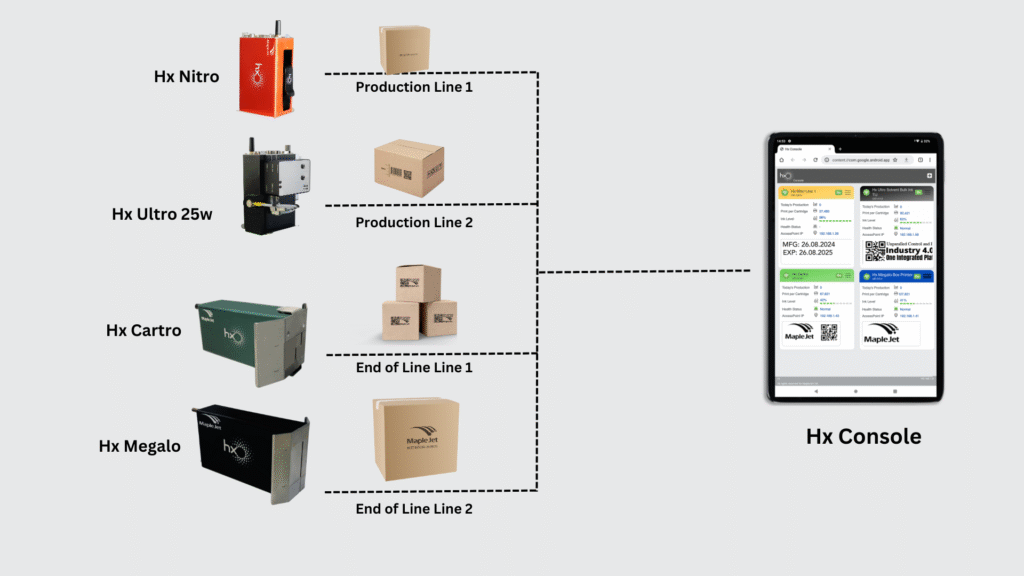

Hx Console – Centralized Print Management Across Multiple Lines

To unify printer operations across production lines, Hx Console offers a single dashboard for managing all Hx printers—from message distribution to performance analytics. This powerful control system is essential for operations that require consistency across facilities or wish to minimize human error and downtime.

Key Features:

- Centralized message creation and distribution

- Multi-line printer control and monitoring

- Real-time diagnostics and maintenance status

MapleJet Cloud – Advanced Insight into Production and Traceability

For businesses seeking a more advanced, connected environment, MapleJet Cloud integrates coding systems with production data, analytics, and traceability tools. It enhances visibility across the supply chain, supports remote diagnostics, and integrates with MES/ERP systems to align printing with real-time production schedules and traceability protocols.

Key Benefits:

- Cloud-based access to printer performance and print logs

- Integration with existing production management systems

- Remote firmware updates and security management

Conclusion: A Fully Integrated Approach to Secondary Packaging Excellence

From compact single-head coders to wide-format, high-capacity solutions, MapleJet’s full range of TIJ printers and management tools delivers precision, reliability, and control at every level of secondary packaging. When paired with Hx Console and MapleJet Cloud, manufacturers can achieve end-to-end visibility and control, ensuring every printed code is accurate, compliant, and production-optimized.

Whether scaling up a single line or overseeing a multi-facility network, MapleJet provides the tools and technologies to streamline coding operations and future-proof packaging infrastructure.

Recent Comments