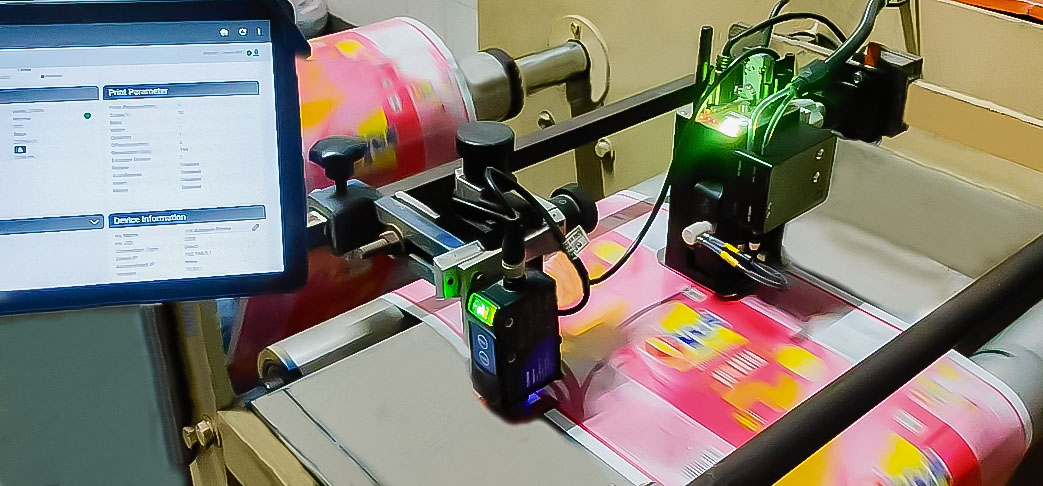

One method widely adopted for flexible materials is roll-to-roll (R2R) processing—a continuous manufacturing technique where material such as film, foil, or paper is unwound, processed, and rewound. Within this setup, a winder-rewinder system plays a key role by enabling materials to be efficiently wound and rewound while various processes, such as coding and marking, are applied.

During this stage, coding and marking equipment—whether a roller coder, inkjet printer, or batch coder—applies essential information such as expiry dates, batch numbers, barcodes, or regulatory details directly onto the substrate. This ensures that pre-printed films and labels are not only branded but also compliant with traceability and safety requirements.

By integrating coding into an offline roll-to-roll or winder-rewinder process, manufacturers gain greater flexibility and efficiency, since coding can be completed independently of the main production line. This is where MapleJet’s Hx Ultro Bulk Ink TIJ Printer excels, offering a high-performance solution for large companies managing high-volume pre-printed films and label rolls.

Roll-to-Roll vs. Winder-Rewinder: Understanding the Difference

While the terms are often used interchangeably, there are subtle but important differences that matter in industrial applications:

- Roll-to-Roll (R2R) Processing

Refers to the broader manufacturing method for flexible materials, where the substrate moves continuously from an unwound roll, through one or more processing steps (such as printing, laminating, or coding), and is then rewound. It’s a complete production workflow that supports high-volume, continuous operations. - Winder-Rewinder Systems

These are specific machines within a roll-to-roll process, designed to unwind material, pass it through a processing station (such as a coding unit), and then rewind it neatly. Winder-rewinder systems are commonly used in offline coding and marking setups, allowing manufacturers to apply variable data to pre-printed rolls before they’re fed into filling or packaging lines.

In short, roll-to-roll is the process, while winder-rewinder is the machine that enables flexible handling of rolls during offline coding tasks.

Why Offline Printing Matters for Large-Scale Production

Many large companies rely heavily on in-line coding, but offline roll-to-roll printing offers several advantages, especially for operations managing pre-printed substrates:

- Uninterrupted Production Flow

With offline printing, coding tasks are separated from the main production line. This eliminates the risk of downtime or slowdowns on high-speed filling and packaging equipment, ensuring the production line runs continuously while variable data is applied separately. - Batch Coding Flexibility

Offline systems allow entire rolls of pre-printed films or labels to be coded in advance. This means manufacturers can run batch jobs, preparing coded materials ready for different SKUs or regulatory markets without interrupting primary production schedules. - Error Reduction and Quality Assurance

By dedicating a controlled offline process for coding, operators can detect and correct print issues before rolls are integrated into packaging lines. This minimizes costly recalls, rework, and waste. - High-Speed, High-Volume Capability

Offline roll-to-roll printing ensures thousands of meters of film or large volumes of labels can be coded with consistent precision, meeting the needs of global-scale operations.

Hx Ultro Bulk Ink TIJ – Designed for High-Volume Offline Applications

The Hx Ultro Bulk Ink Thermal Inkjet Printer is specifically engineered for demanding production environments where speed, accuracy, and cost efficiency are non-negotiable. Its features align perfectly with the requirements of roll-to-roll offline coding:

- Bulk Ink System for Extended Runs

With up to 160ml ink capacity, the Hx Ultro reduces cartridge changes, maximizing uptime and cutting consumable costs—ideal for long batch jobs. - High-Speed Printing

Capable of coding at line speeds exceeding 200 m/min, the Hx Ultro keeps pace with offline rewinders and roll-to-roll systems. - Superior Ink Technology

Compatible with advanced solvent and water-based ink, the Hx Ultro ensures excellent adhesion on flexible films, paper labels, and other substrates. Codes remain sharp, fade-resistant, and compliant with global packaging standards. - Seamless Integration with Roll-to-Roll Systems

Compact and versatile, the printer easily mounts onto offline rewinders and label finishing systems, creating a streamlined coding workflow. - Software and Cloud Connectivity

Through Hx Manager and Hx Console production managers can remotely design messages, monitor printer performance, and manage coding tasks across multiple sites, ensuring standardization and traceability. While MapleJet Cloud provides hourly and daily production analytics, spotlighting peak times, bottlenecks, and maintenance opportunities—so teams can refine staffing, materials scheduling, and capacity forecasts with precision.

Advantages of Choosing Offline Printing with Hx Ultro for Large Companies

For multinational manufacturers handling millions of packages monthly, combining offline roll-to-roll printing with the Hx Ultro Bulk Ink TIJ provides strategic advantages:

- Operational Efficiency: Decoupling coding from packaging minimizes downtime and ensures uninterrupted high-speed production.

- Scalability: Handle multiple SKUs, languages, or compliance requirements with batch-coded rolls.

- Cost Savings: Bulk ink reduces consumable costs while eliminating waste from online errors.

- Quality and Compliance: Consistent, high-resolution codes ensure traceability and meet regulatory requirements.

- Sustainability: Reduced solvent usage and efficient bulk ink consumption align with corporate environmental goals.

Conclusion

For large companies seeking to optimize productivity and flexibility, roll-to-roll offline printing with the Hx Ultro Bulk Ink TIJ Printer is a robust solution. It allows pre-printed films and labels to be coded efficiently, without impacting high-speed production lines, while delivering durable, compliant, and cost-effective results.

By adopting this approach, manufacturers can future-proof their operations—meeting today’s demands for speed, quality, and compliance while ensuring the scalability required for tomorrow’s growth.

Contact Us

To learn how the Hx Ultro Bulk Ink TIJ Printer can enhance your offline roll-to-roll printing operations, get in touch with our team today. Our experts can provide tailored solutions, demonstrations, and support to optimize your production workflow.

Recent Comments