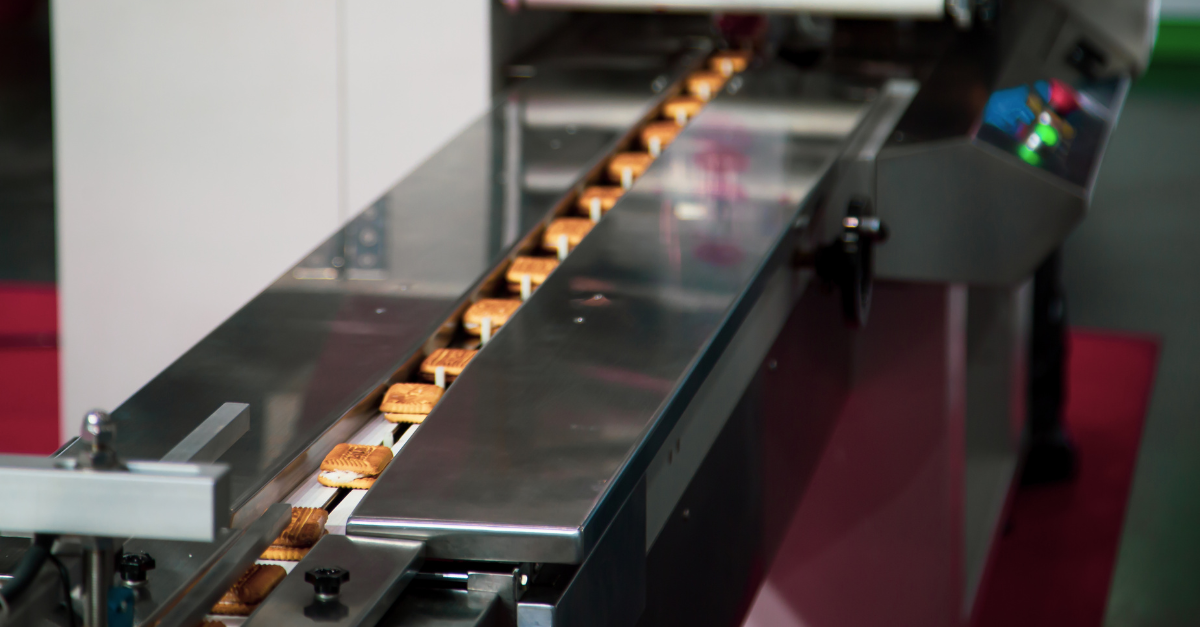

Horizontal Form Fill Seal (HFFS) machines are the backbone of many large-scale packaging operations, especially in industries like food, pharmaceuticals, and consumer goods. These machines offer speed, precision, and efficiency by forming, filling, and sealing products in a continuous flow. But when it comes to product coding—batch numbers, expiry dates, barcodes, or traceability information—many companies still face challenges with older coding technologies that slow production or increase downtime.

This is where MapleJet’s Hx Ultro Bulk Ink TIJ Printer comes in—purpose-built for high-volume, high-speed production environments that demand reliability and efficiency.

The Role of Coding on HFFS Packaging

HFFS machines are widely used in different formats, including:

- Flow wrap machines – for bars, bakery products, and confectionery.

- Pillow pouch machines – for snacks, frozen foods, and dry goods.

- Stick pack and sachet machines – for powders, condiments, and single-serve products.

- Specialty pouches (3-side/4-side seal) – for pharma, healthcare, and nutraceuticals.

Each format presents unique coding challenges—whether it’s small print areas on stick packs, high-speed continuous film movement on flow wraps, or the need for rotation to align codes properly with sealing windows. Traditional printers, such as TTOs and CIJs, often struggle with these demands due to frequent maintenance, downtime, or consumable costs.

Challenges with Existing Coding Technologies

Large manufacturers using HFFS machines often encounter issues such as:

- High maintenance requirements (especially with CIJ systems).

- Frequent ribbon changes (with TTOs), leading to downtime.

- Ink waste and high running costs in high-speed operations.

- Inconsistent print alignment when the film shifts or sealing windows are not perfectly aligned.

- Limited real-time monitoring and data integration, making it harder to scale up production with Industry 4.0 initiatives.

Why Hx Ultro is the Best Choice for HFFS Applications

The Hx Ultro Bulk Ink TIJ Printer is designed with large-scale HFFS operations in mind, combining speed, automation, and connectivity to deliver a smarter coding solution. Here’s what makes it stand out:

1. High-Speed Capability – 240m/min

Perfect for high-volume flow wrap and pillow pouch lines. The Hx Ultro ensures crisp, high-resolution prints even at maximum machine throughput—keeping up with demanding production speeds.

2. Rotate Option for Proper Alignment

Printing windows in HFFS can vary depending on package design. Hx Ultro’s rotate function allows you to easily adjust and align the code to the exact spot—ensuring compliance and readability every time.

3. High-Volume Bulk Ink System

With bulk ink capacity, Hx Ultro reduces the frequency of cartridge changes, minimizing downtime and consumable interruptions—ideal for 24/7 operations.

4. Interlock Signal Connection

Seamlessly integrate with your HFFS host machine. The printer communicates real-time signals such as:

- Fault – alerting when attention is needed.

- Busy (Printing) – monitoring live status.

- Ready – ensuring operators know when the printer is set for production.

5. ‘Auto Notify’ System

Stay informed in real time. Whether it’s low ink, job completion, or online data received, notifications can be sent via USB, RS232, or Wi-Fi (HTTP) to your preferred channels—keeping operators and supervisors updated instantly.

6. Daily Production Report

Get actionable insights. Reports can be accessed through Hx Manager or, for more advanced analytics, through MapleJet Cloud—helping management track efficiency, production volume, and overall performance.

7. Multiple Line Monitoring with Hx Console

For companies with multiple HFFS lines, Hx Console allows centralized monitoring and control of all Hx printers—saving time, reducing errors, and simplifying coding management.

The Bottom Line

For large manufacturers running high-volume HFFS machines, coding should never be the bottleneck. The Hx Ultro Bulk Ink TIJ Printer eliminates the common challenges of older technologies while delivering:

✅ Speed and precision at 240m/min

✅ Long, uninterrupted runs with bulk ink

✅ Real-time connectivity and smart alerts

✅ Scalable insights with MapleJet Cloud

✅ Seamless integration with existing HFFS systems

With the Hx Ultro, your HFFS lines achieve reliable, cost-efficient, and Industry 4.0-ready coding—helping you focus on production while ensuring compliance and brand integrity.

👉 Looking to upgrade your HFFS coding system? Contact MapleJet today to learn how Hx Ultro can transform your high-volume packaging operations.

Recent Comments