Thermal inkjet printers, known for their speed, quality, and versatility, have become a popular choice in food, beverage, and pharmaceutical applications, often replacing traditional technologies like TTO (thermal transfer overprinting) and CIJ (continuous inkjet) printers. This shift is due to its ability to provide high-resolution, fast-drying codes on food packaging, making it ideal for date coding, branding, and marking product information.

Discussing the advantages of thermal inkjet printing is crucial as it helps both businesses and consumers understand the technology’s value. By highlighting its speed, quality, versatility, and cost-effectiveness, readers can make informed decisions about adopting this technology for their specific printing needs.

High-Quality Output

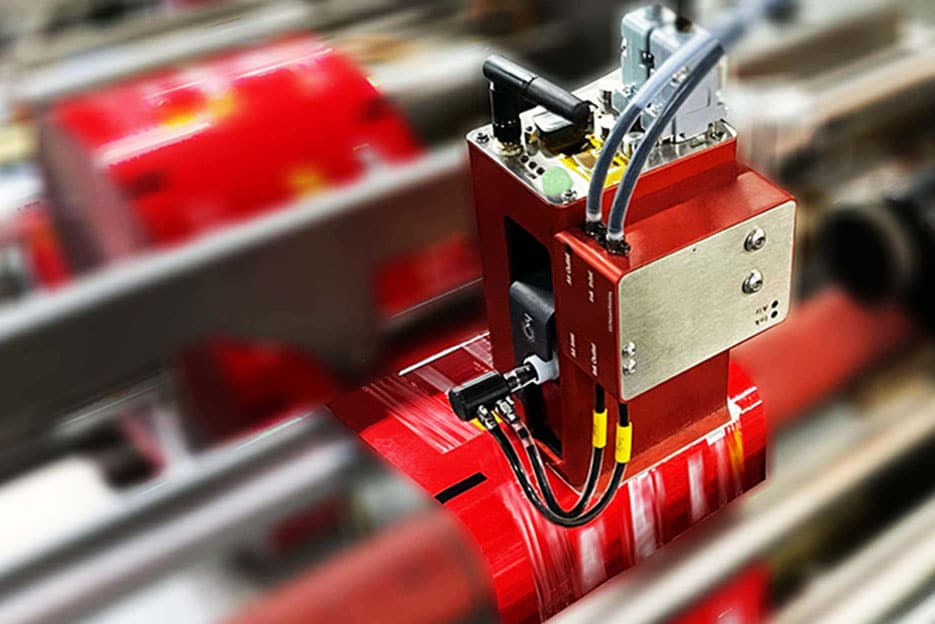

Thermal inkjet printers are known for their ability to produce exceptionally crisp and sharp codes. The precise control of ink droplet placement and the high resolution of these printers result in clear, legible, and professional-looking codes on various substrates. This characteristic is particularly crucial in industries like food packaging, where the accuracy and clarity of product information, expiration dates, and barcodes are of paramount importance for both manufacturers and consumers.

High-Speed Marking

When coupled with solvent-compatible fast-drying ink, thermal inkjet printers exhibit exceptionally fast printing capabilities. The combination of thermal inkjet technology and these inks allows for rapid drying of ink on various substrates. This speed is particularly advantageous in industries such as packaging and labelling, where immediate adhesion and resistance to smudging or fading are essential.

High Volume Coding

Thermal inkjet (TIJ) now comes with bulk ink systems that are particularly well-suited for high-volume printing. These systems offer substantial ink reservoirs that can handle the demands of continuous and large-scale printing operations, reducing the need for frequent cartridge replacements. This makes TIJ bulk ink an efficient choice for industries where uninterrupted production and reduced downtime are critical, providing both cost savings and enhanced operational productivity.

Cost-Effectiveness

Thermal inkjet printing proves cost-efficient for production lines due to its lower initial investment, minimal maintenance needs, and reduced material waste. These printers consume ink efficiently, operate at high speeds, and offer versatility, reducing costs related to equipment changes. Their energy efficiency and long-term reliability also contribute to overall savings, making thermal inkjet technology a smart choice for businesses looking to optimize production while controlling operational expenses

Application and Substrate Versatility

Thermal inkjet (TIJ) printing boasts remarkable versatility, enabling high-quality printing on an extensive range of materials. This includes flexible packaging materials like pouches, metal tin cans, cardboard boxes, foil packaging, labels, plastic containers, glass bottles, wood, textiles, ceramics, and glass products. TIJ printers can also be used across multiple industries including food, beverage, automotive, pharmaceuticals, and industrial applications.

In the food industry, it is used for date coding, labelling, and packaging, ensuring product traceability and compliance with safety standards. Beverage companies utilize TIJ printing for labelling and branding on bottles, cans, and packaging, enhancing product visibility and consumer engagement. In the pharmaceutical sector, TIJ technology is instrumental in printing expiration dates and batch numbers on drug packaging, contributing to regulatory compliance and quality control.

User-Friendliness

Setting up and using thermal inkjet printers is exceptionally user-friendly. Once installed, printing is as straightforward as selecting your print job and clicking “print.” Maintenance, including ink cartridge replacement and printhead cleaning, is minimal. The simplicity of thermal inkjet printers, combined with their quick and precise printing capabilities, makes them a hassle-free choice for a wide range of applications.

Environmentally Friendly

With its minimal consumable waste and energy-efficient operation, TIJ technology reduces environmental impact. The precise ink droplet control minimizes the use of ink, resulting in less waste and fewer discarded consumables. Additionally, TIJ printers are generally energy-efficient, consuming less power during operation, which not only reduces energy costs but also lessens their overall carbon footprint. Moreover, unlike CIJ (continuous inkjet) printers, they eliminate the need for consumable makeup solutions, further contributing to a cleaner and more sustainable printing process.

Traceability

Thermal inkjet printers excel in the ability to personalize prints, labels, barcodes, and GS1 Datamatrix codes, enhancing traceability and brand customization. This feature is especially valuable in industries where individualized data, branding, and traceability are essential, such as food, pharmaceuticals, and manufacturing. Thermal inkjet printers can swiftly generate unique information on each item, whether it’s a product label, barcode, or GS1 Datamatrix code, contributing to efficient inventory tracking, quality control, and effective brand differentiation.

Conclusion

The key advantages of thermal inkjet printing include high-quality output, fast printing capabilities, cost-effectiveness, versatility in material printing, ease of setup and use, minimal maintenance, environmental friendliness with reduced consumable waste, and the ability to personalize prints, labels, barcodes, and GS1 Datamatrix codes for enhanced traceability and branding. These attributes collectively make thermal inkjet printing a compelling choice for a wide range of applications across various industries.

To explore thermal inkjet printing options or obtain more information, contact Maplejet, a trusted industry expert in this technology. They can provide invaluable insights and solutions tailored to your specific requirements.

Recent Comments