Home » Megalo Industrial Inkjet Printer

Hx Megalo Printer

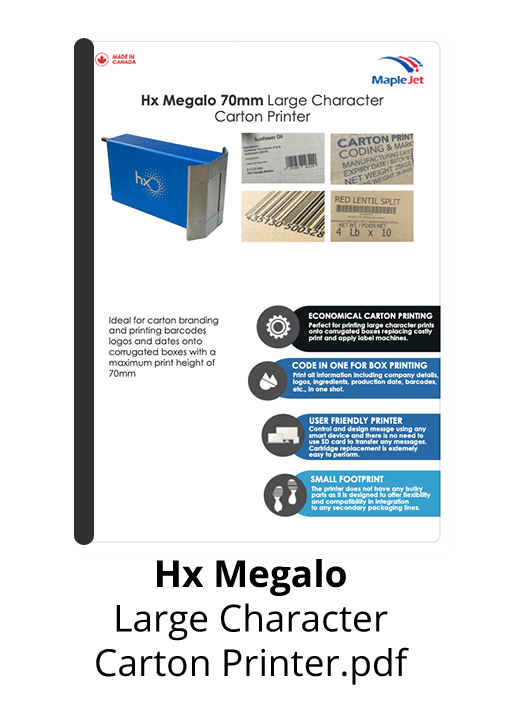

Large Character Carton Printer

Hx Megalo Large Character Printing on Corrugated & Carton Boxes

The Hx Megalo printer, with its single head delivering a 70mm print height, excels in large character printing for highly visible branding on porous materials. Its advanced oil-based ink is fade-proof, heat-resistant, and eco-friendly with OK bio based certification. With a 160ml bulk ink capacity, it ensures long operational periods and minimal ink replenishment. Integrated with Hx Manager software, accessible via smart devices, it offers comprehensive control and monitoring for efficient workflow.

MapleJet’s Hx Megalo printer revolutionizes large character printing with unmatched precision and speed. Designed for industries requiring durable, high-resolution markings, this large character inkjet printer provides legible codes on materials like corrugated boxes, pallets, and industrial packaging.

Why Choose Hx Megalo Carton Printer

Large Character Printing: The Hx Megalo excels at producing large character prints, ensuring your branding, logos, and essential information are highly visible and impactful.

Reliability and Efficiency: Designed to support continuous, high-speed production lines, the Hx Megalo minimizes downtime and maximizes productivity.

Superior Print Quality: Achieve crisp, clear prints that enhance the visibility and appeal of your packaging, ensuring your brand stands out.

Eco-Friendly Ink Options: Our commitment to sustainability is reflected in our use of OK biobased ink, reducing environmental impact without compromising on quality.

Versatility and Flexibility: The Hx Megalo is perfect for a wide range of applications, from branding and logos to essential product information, adapting to your specific needs with ease.

-

ADVANCED FEATURES

-

MESSAGE DESIGN

-

INK TYPES

-

CARTON PRINTER BROCHURE

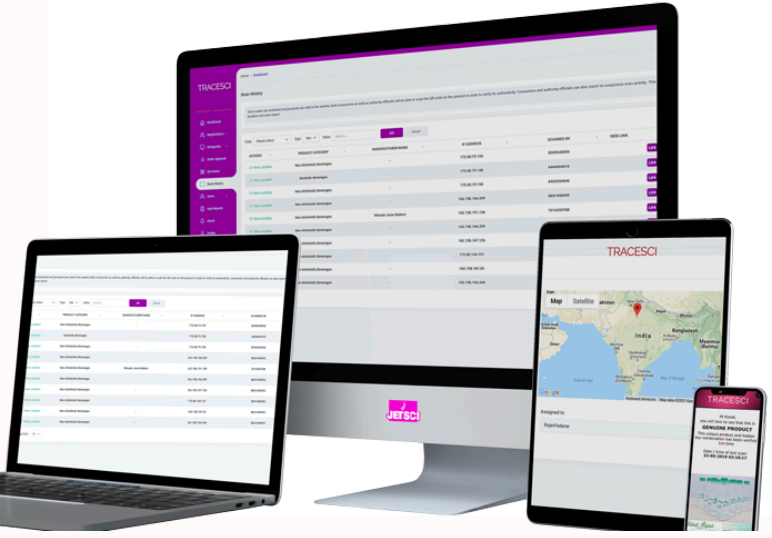

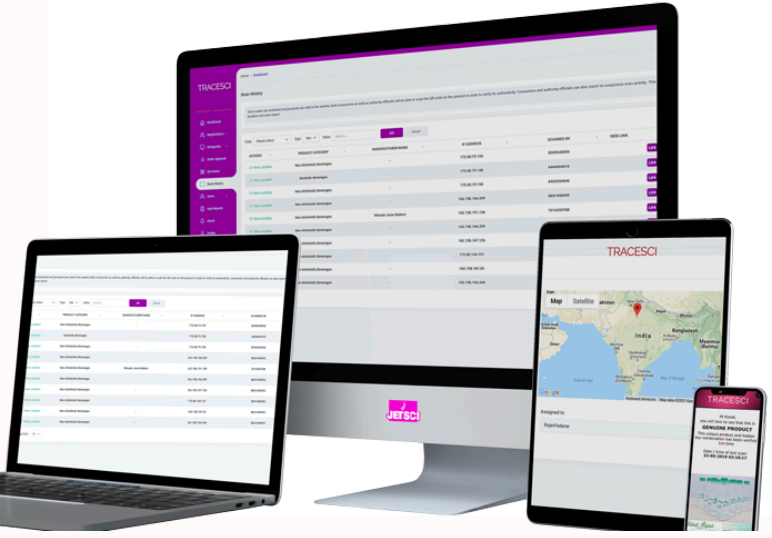

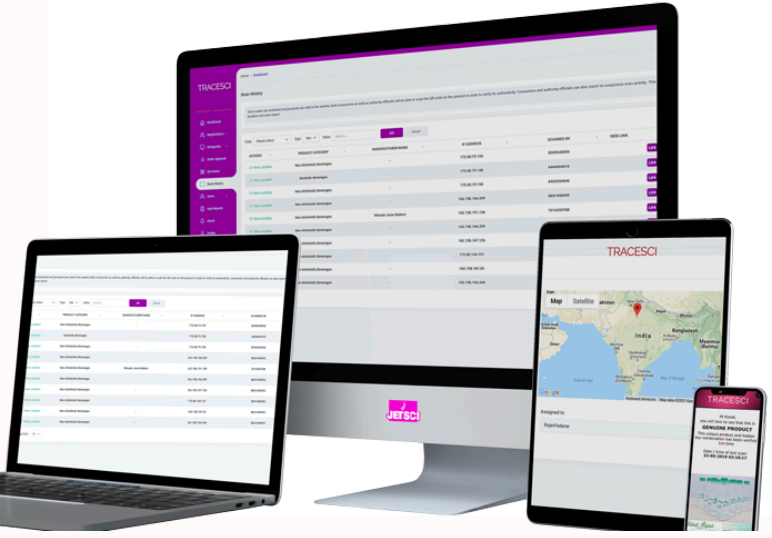

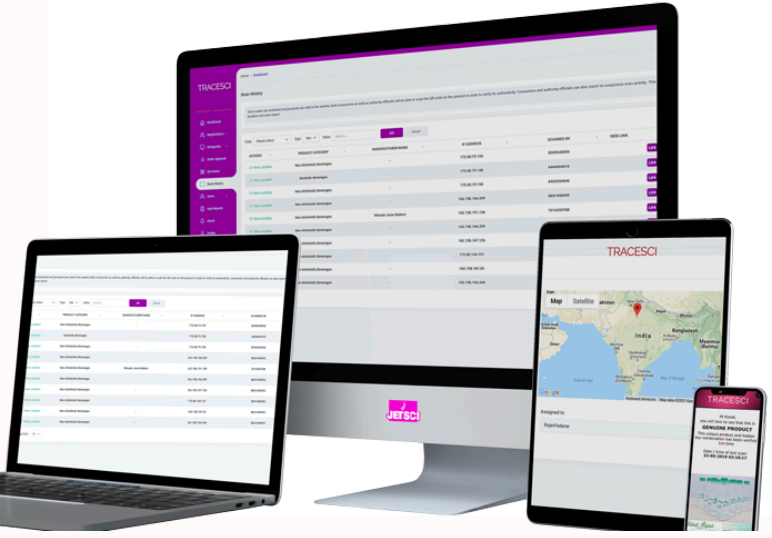

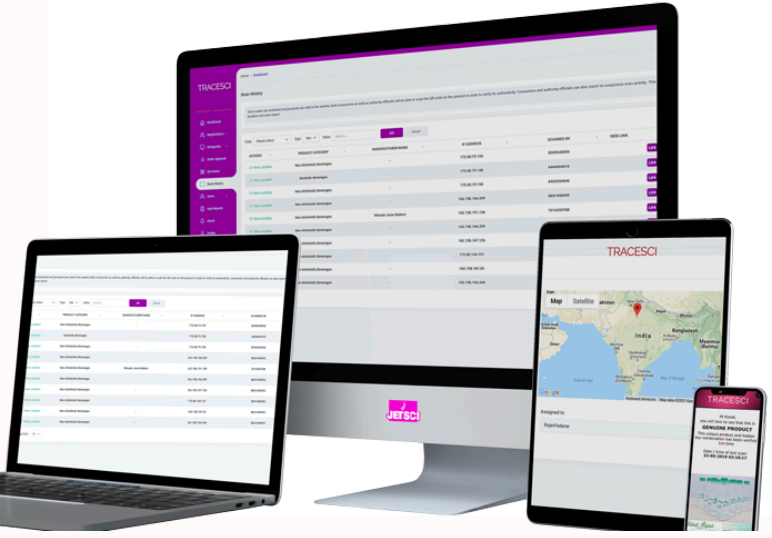

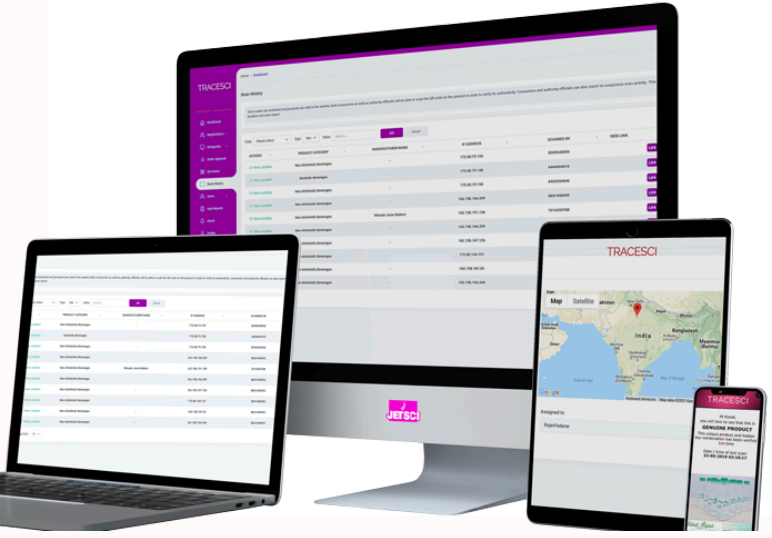

MapleJet Cloud Integration:

- Real-Time Monitoring & Management: Access real-time production data, printer status, performance history, and downtime reports. Design messages and control printers remotely.

- Alerts & Notifications: Email notifications on ink status and updates to ensure timely response. Warning insights from printer health check history.

Hx Console:

- Printer Health Check: Monitor printer status with real-time warnings and suggested remedies for quick issue resolution.

- Economy Mode: Reduce ink consumption by 50%, increasing print output per cartridge and lowering costs.

- Field Upgrade: Enable future software upgrades, extending the printer’s lifecycle beyond industry standards.

- Auto Notify: Events such as ‘low ink level’, ‘printing completed’, and’online data received’ can be automatically communicated by choosing selected channels e.g. USB, RS232, and Wi Fi (HTTP)

- Auto Pilot: Allows other external device to control and monitor Hx Printer. Any third party device (e.g. PLC), system, or software can send a command to Hx Printer.

- Daily Production Report: Provides an hourly print report of the printer giving an overview of the complete daily production

- External Data: Easy integration to external devices e.g. PLC, weighing scale, etc for printing variable data. Auto calculation and printing of the product weight

- Ink Estimation Calculator: Provides an estimate number of prints per cartridge based on the message and other parameters.

Simple Message Editor:

- User-Friendly Interface: Offers a clean, intuitive interface designed for effortless navigation, enabling operators to create and modify messages quickly.

- Text Design: Create customized text for product labeling, batch codes, or other critical information, with options for various fonts, sizes, styles, and alignments.

- Production and Expiration Dates: Automatically generate production and expiration dates with customizable formats to meet regional and industry-specific compliance.

- Print Settings Control: Configure essential print settings, such as print speed, resolution, and direction, to ensure optimal print quality and efficiency for different substrates and production environments.

- Message Management: Save frequently used messages for easy retrieval, editing, and reuse, reducing setup times and improving production line efficiency.

- Encoder Parameters Activation: Seamlessly activate and configure encoder settings to synchronize printing with variable line speeds, ensuring consistent print quality regardless of production speed changes.

External Data Integration for Real-Time Printing:

- Dynamic Data Fields: Design messages that incorporate external data sources, such as product databases to print dynamic and real-time information, including serial numbers, batch codes, and more.

- Seamless Connectivity: Connect the printer directly to external data sources, enabling real-time data retrieval for on-the-fly printing without manual input or delays.

- Versatile Data Formats: Support for various data formats (CSV, XML, SQL, etc.) allows integration with a wide range of data management systems, enhancing flexibility and adaptability to different production environments.

Poroen Ink is a high-performance, oil-based ink specially formulated for the Hx Megalo large character printer, capable of printing characters up to 70mm. This ink provides excellent adhesion and durability on various porous surfaces, such as corrugated boxes, paper, and wood, ensuring clear and legible prints even in challenging environments.

Poroen Ink is also a certified OK biobased ink, containing renewable resources, making it a more environmentally friendly option. With its unique formulation, it delivers consistent print quality, quick drying times, and minimal maintenance requirements, making it ideal for high-volume industrial applications where both performance and sustainability are essential.

The Hx Megalo printer offers advanced technology to produce bold, clear prints that remain sharp even in challenging environments. With high-speed capabilities and robust construction, the printer excels in demanding production lines, ensuring efficiency without compromising on quality. This innovative solution supports versatile ink options for porous and nonporous surfaces, meeting a wide variety of packaging needs.

Identify trends, peak hours, and bottlenecks of your production line to maximize uptime and reduce downtime.

- Optimizes resource allocation on peak hours and plan maintenance on off-peak hours

- Eliminates unexpected downtime by planning ink cartridge replacement

- Sets realistic production targets based on monthly production report

- Empowers production manager to make informed choices that enhance their process

Additionally, its user-friendly interface streamlines operation, reducing setup times and minimizing downtime. You can rely on MapleJet’s Hx Megalo printer for reliable, cost-efficient large character printing that enhances traceability and compliance. Contact us today to learn more about our solutions and systems.

What Our Customers Say About Us!

© 2026 MapleJet Middle East.

- Home

- Products

- Industries

- Applications

- Resources

- About Us

- Contact Us

Founded in 2007 in Toronto, Canada, MapleJet’s Business philosophy is based on finding the perfect balance between quality, simplicity and low cost of ownership.

Head Office

Warehouse No: T5-066

Saif Zone

Sharjah – UAE

Phone: +971558990436

Landline: +971 6 546 0545