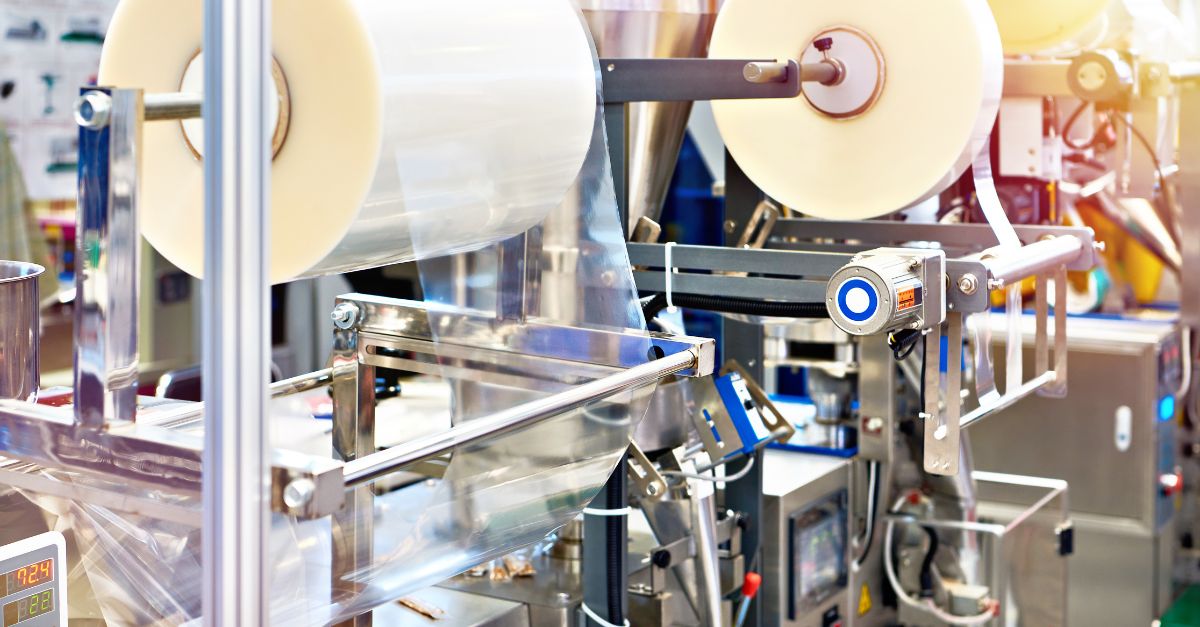

Vertical Form Fill Seal (VFFS) machines are central to high-volume packaging operations across industries such as food, pharmaceuticals, agriculture, pet food, and personal care. While they excel in throughput and flexibility, coding and marking often become a bottleneck—impacting efficiency, compliance, and cost.

The Hx Ultro Fully-automated Bulk Ink Thermal Inkjet (TIJ) Printer is engineered to solve these challenges, delivering continuous, high-resolution coding with reduced downtime and operating costs, even in the most demanding VFFS environments.

Challenges in VFFS Coding

VFFS lines operate at high speeds with minimal tolerance for stoppages, making the coding process highly sensitive to any inefficiencies. Common issues include:

- Frequent cartridge replacements interrupt continuous operation

- Downtime during ink changeovers is impacting shift productivity

- Inconsistent print quality at higher line speeds

- Increased maintenance requirements for print systems

- Elevated cost per print due to high cartridge consumption

These challenges are particularly critical in industries where packaging must meet strict traceability and compliance standards, such as food, beverage, and pharmaceuticals.

The Hx Ultro Bulk Ink TIJ Advantage

- Bulk Ink Delivery System – Extends operational runtime by feeding ink from a high-capacity reservoir, significantly reducing changeovers.

- Minimized Operator Intervention – Automated ink delivery minimizes manual handling, lowering the risk of human error.

- Consistent High-Resolution Printing – Maintains crisp date codes, lot numbers, and QR codes even at the upper limits of VFFS line speeds.

- Optimized Cost per Print – Bulk ink usage reduces cartridge dependency, lowering consumable costs in high-volume production.

- Reliable Substrate Compatibility – Supports porous and certain flexible materials commonly used in snack, powder, and dry goods packaging.

Types of VFFS Machines and Coding Considerations

Different VFFS machine types demand equally adaptable coding technology. The Hx Ultro’s flexibility ensures optimal performance across all configurations:

- Intermittent Motion VFFS Machines

- Operation: Step-by-step form, fill, and seal process for precise control.

- Coding Fit: Ideal for delicate products—Hx Ultro ensures high-quality prints during slower cycle pauses.

- Continuous Motion VFFS Machines

- Operation: No halts between packaging cycles; higher throughput.

- Coding Fit: Hx Ultro maintains code clarity at high line speeds without compromising resolution.

- Rotary VFFS Machines

- Operation: Rotating drum or carousel for continuous motion.

- Coding Fit: Seamless integration for high-speed coding on smaller packages.

- Auger-Filler VFFS Machines

- Operation: Screw mechanism for precise powder/granule filling.

- Coding Fit: Crisp, dust-resistant printing for powdered products like coffee or spices.

- Liquid-Filler VFFS Machines

- Operation: Specialized liquid-filling systems for beverages, sauces, and pharmaceuticals.

- Coding Fit: Reliable, smudge-free printing on laminated and flexible liquid packaging.

- Multi-Lane VFFS Machines

- Operation: Parallel packaging on multiple lanes for maximum efficiency.

- Coding Fit: Consistent multi-lane code placement managed from a single Hx Ultro control interface.

Real-World Applications

The Hx Ultro supports a wide spectrum of VFFS applications:

- Food Industry – Snack Packaging

High-speed coding of chips, nuts, and pretzels with variable date/lot data across different bag sizes. - Pharmaceutical Industry – Powder Medication

Accurate, compliant coding on medical-grade films for regulatory traceability. - Agricultural Industry – Fresh Produce

Durable code printing on protective film to extend shelf life and prevent waste. - Pet Food Industry – Treats and Snacks

Multiple bag formats coded with consistency to match brand and batch control needs. - Personal Care Industry – Hygiene Products

Efficient batch coding for diapers, wipes, and similar items in flexible packaging.

Performance in High-Volume Environments

When integrated into a VFFS line, the Hx Ultro provides stable, repeatable code placement with precise ink drop control. This ensures that every printed character—whether alphanumeric or machine-readable—is sharp and scannable. The reduction in unplanned stoppages directly contributes to higher OEE and better production forecasting.

Integration and Industry 4.0 Compatibility

The Hx Ultro operates with Hx Manager, a printer management platform that enables:

- Remote message creation and editing

- Real-time printer status monitoring

- Seamless integration into Industry 4.0 and smart factory systems

This allows packaging line managers to oversee coding operations from any connected device, ensuring faster response to production changes.

Conclusion

VFFS machines—whether intermittent, continuous, rotary, or specialized—require a coding solution that can match their speed, versatility, and output quality. The Hx Ultro Bulk Ink TIJ Printer delivers:

- Reduced downtime through bulk ink efficiency

- High-resolution coding across substrates

- Lower total cost of ownership in high-volume runs

- Seamless integration with any VFFS configuration

For packaging engineers, plant managers, and operations leaders, the Hx Ultro is more than a coding system—it’s a performance multiplier for VFFS operations.

📩 Contact us to explore integration options for your specific VFFS line and application requirements.

Recent Comments