Printing on plastic surfaces is crucial across various industries, from food and beverage packaging to automotive parts. The need for clear, durable, and high-quality prints on plastics like PET, PP, and PVC has led many businesses to explore different printing technologies. One common question that arises is: can thermal inkjet (TIJ) printers effectively print on plastic?

TIJ Printing on Plastic: How Does It Work?

Thermal Inkjet (TIJ) printing uses heat to eject ink droplets onto a surface. Known for its high-resolution output, TIJ is widely used for printing barcodes, batch codes, and graphics. However, printing on plastic presents some specific challenges:

- Ink Adhesion: Plastics are smooth and non-porous, which can make ink adhesion difficult. TIJ printers use specialized inks, including solvent-based and UV-curable inks, that bond well with plastic materials.

- Drying Time: Since plastic does not absorb ink, drying time becomes critical. TIJ printers with fast-drying inks help prevent smudging, especially in high-speed production environments.

- Surface Energy: The surface energy of plastic affects how ink spreads. TIJ printers must be calibrated to optimize ink flow and maintain consistent print quality across different types of plastic.

- Non-Contact Printing: TIJ technology’s non-contact nature ensures that delicate or irregular plastic surfaces remain undamaged during printing, making it suitable for flexible packaging.

Applications of TIJ Printing on Plastic:

TIJ printers are versatile and used across many applications involving plastic. Here are some key areas where TIJ printing excels:

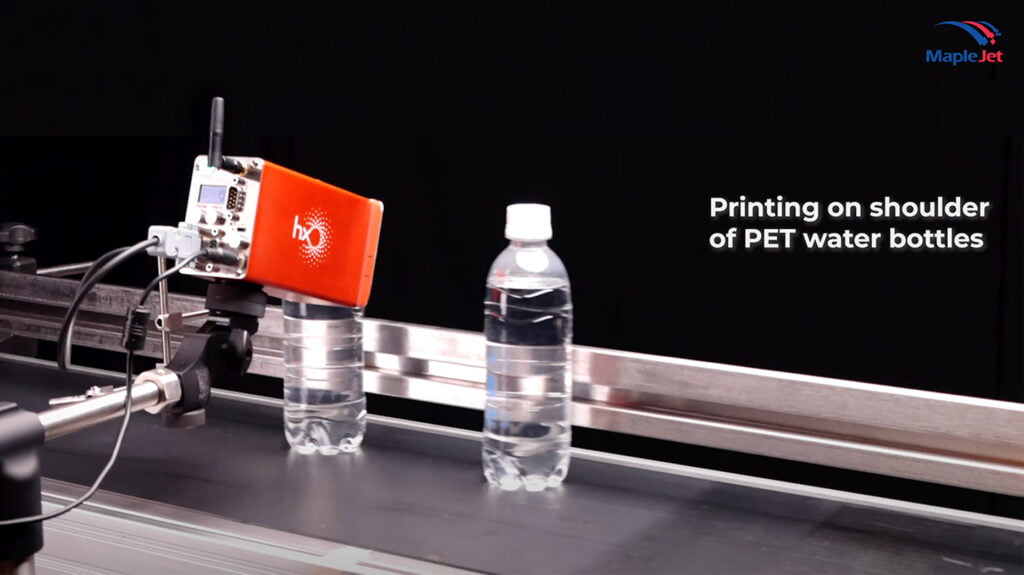

- Food and Beverage Packaging

- TIJ printers are commonly used to print expiration dates, batch codes, barcodes, and product information directly onto plastic packaging like PET bottles, shrink wraps, and plastic trays. This is essential for ensuring compliance with food safety regulations and enhancing traceability throughout the supply chain.

- Flexible Packaging Films

- TIJ printers are ideal for printing on flexible plastic films used in snack foods, frozen goods, and other consumables. These surfaces often require high-speed, non-contact printing to maintain packaging integrity, ensuring that product codes and branding are applied without compromising the packaging’s seal or appearance.

- Cosmetics and Personal Care Products

- In the cosmetics industry, aesthetics are crucial. TIJ printers deliver high-resolution branding, logos, and batch numbers on plastic tubes, bottles, and caps. The non-contact printing process preserves the integrity of even the most delicate packaging while achieving sharp, professional prints.

- Pharmaceutical Packaging

- Pharmaceuticals rely on TIJ printing to produce high-quality, legible prints on plastic medicine bottles, blister packs, and packaging films. TIJ printers ensure that vital information, such as dosage instructions, lot numbers, and expiration dates, remains clear and easy to read, enhancing patient safety.

- Electronics and Automotive Components

- TIJ printers mark serial numbers, part codes, and safety warnings on plastic components used in electronics and automotive industries. This technology delivers precise, smudge-resistant prints, ensuring that critical information remains visible, even in harsh environments or after prolonged use.

- Industrial Parts and Tools

- TIJ printers are used to print on plastic industrial parts, such as cables, pipes, and plastic enclosures, aiding in identification and inventory management. These permanent markings withstand extreme conditions, including exposure to chemicals and UV light, making them ideal for industrial applications.

- Household Goods and Consumer Products

- TIJ printing offers a quick and reliable way to add branding, product information, or safety instructions to household items like plastic containers, bins, and utensils. Its ability to print on curved and irregular surfaces without contact makes it particularly suited for these everyday products.

- Chemical and Hazardous Goods Packaging

- TIJ printers handle the demanding requirements of printing on plastic packaging for chemicals, pesticides, and hazardous materials. Solvent-resistant inks ensure that prints remain legible, even when exposed to corrosive substances or extreme conditions, enhancing safety and regulatory compliance.

How MapleJet TIJ Printers Provide Superior Solutions

MapleJet printers are designed to address the specific challenges of printing on plastic. Here’s what sets them apart:

- Specialized Ink Formulations: MapleJet’s TIJ printers support a wide range of inks tailored for plastic surfaces. These inks are engineered to adhere strongly, dry quickly, and endure handling, transport, and environmental exposure, keeping prints intact.

- High-Resolution Output: With resolutions up to 600 dpi, MapleJet printers are perfect for intricate details on small plastic surfaces, such as cosmetics packaging or electronic parts. Every barcode, text, or graphic remains sharp and readable.

- User-Friendly Integration: MapleJet printers integrate easily into various production lines. They can print on many types of plastics without complex adjustments, enhancing their versatility.

- Reliable Performance in High-Speed Environments: For industries where speed is crucial, such as food and beverage packaging, MapleJet printers deliver consistent quality at high speeds. They help businesses keep up with production demands while ensuring print clarity and adhesion.

- Advanced Features for Consistency: MapleJet printers come with features like adjustable print heights, various mounting options, and intuitive interfaces. These capabilities allow operators to make quick changes, ensuring consistent performance across different plastic materials and production lines.

TIJ printing on plastic is not only achievable but also highly effective when using the right technology. MapleJet’s advanced TIJ printers provide superior quality, flexibility, and ease of use, making them the top choice for businesses needing reliable prints on plastic. Whether you’re dealing with ink adhesion, drying time, or print clarity issues, MapleJet printers are engineered to meet and exceed these challenges.

Ready to improve your plastic printing process? Discover MapleJet’s range of TIJ printers and see how they can enhance your production line. Contact us today for a free demo or consult.

Recent Comments