Many applications such as snacks, personal care, and other consumer products filled and packed on a multi-track form-filling machine require the printing of date codes in a row. This type of application needs coding printers to be integrated into a traverse system that moves from one axis to the other to print the correct multiple rows of codes.

The traverse system helps manufacturers save a substantial amount of investment from installing multiple printheads to print on this application. While a lot of coding technologies including continuous inkjet (CIJ) and thermal transfer overprint (TTO) have introduced a traverse system, Hx Ultro bulk TIJ offers the most ideal and economical solution.

Here is why:

Seamless Integration with web-based control

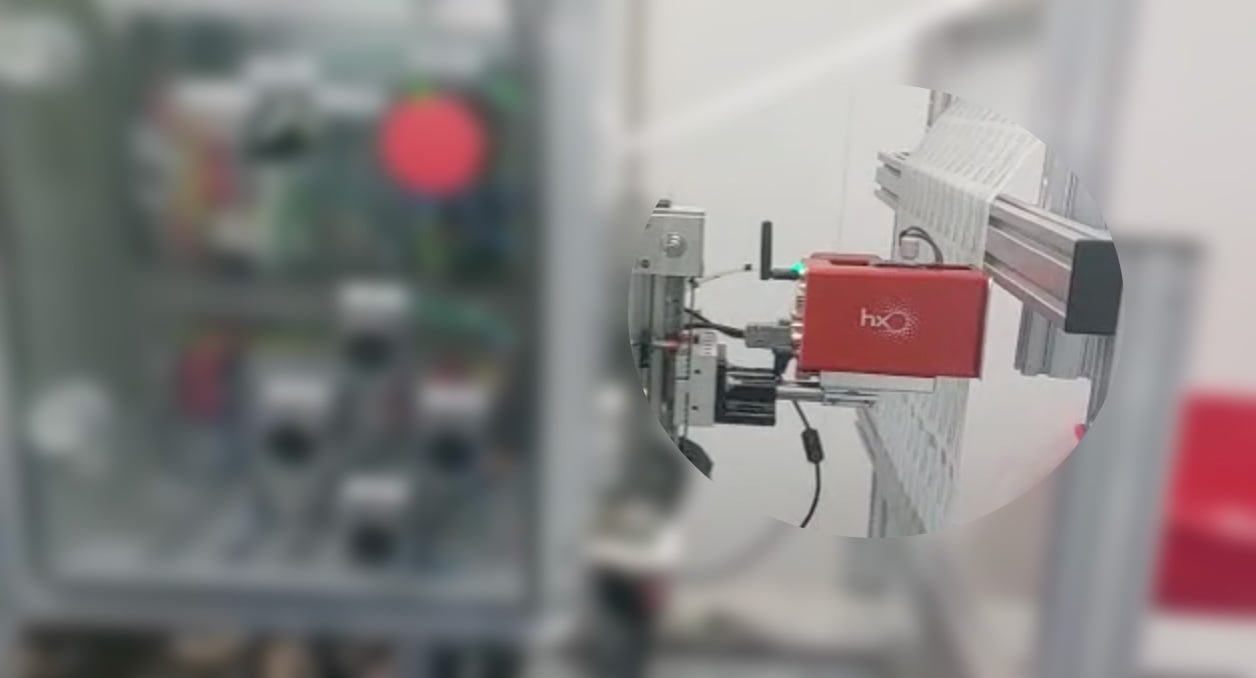

MapleJet Hx Ultro is the first reliable automated bulk ink TIJ with convenient traverse system integration to print date codes onto individual pouches of a multi-lane production line. What makes Hx Ultro ideal for traverse system integration is its lite and small footprint design, unlike other coding technologies with bulky features. Its Wi-Fi capability allows easier printer control even at a distance using any smart device e.g. computer, tablet, or smartphone.

Effect on speed when printing denser codes

Hx Ultro can print more than two lines of message or even denser messages such as barcodes and QR codes without affecting the printing speed. This is an advantage over a CIJ printer since printing denser marks using a CIJ slows down its ability to print fast. While the TTO printer can print barcodes and denser marks at high resolution, the printer must make contact with a product that may affect line speed; hence not suitable for high-speed primary coding.

High-resolution barcode printing

Printing razor-sharp barcodes and machine-readable QR codes are always features that the TIJ printer excels over CIJ technology. The only factor to keep in mind for a TIJ printer to print high-resolution barcodes is the throw distance, since the closer the head is to the product the sharper and better print it produces. However, this application does not require the longer throw distance ability of CIJ. Hx Ultro can be placed where the product has a flat surface and the printer can be placed as close as possible to the product for the best print result.

Ink mess and clean up

Thermal inkjet printheads create very little mess on the production line. When minor cleanup is required, a mild alcohol-based cleaning solution can be used to wipe out the ink. On the other hand, the CIJ printing station is typically coated with ink over time and its cleanup procedure requires harsh solvents that may cause a health hazard and may require ventilation for the operator’s safety.

Downtime & Maintenance

Hx Ultro TIJ has little to zero downtime because there are few moving parts such as the ink cassette and ink cartridge. The ink cartridge is only replaced after a million prints and once changed, the printer is as good as new. To maintain the print quality of the head of Hx Ultro, a simple wipe of a lint-free cloth on the nozzle is enough. Other standard maintenance procedures can be done by operators themselves using online training videos when heads are blocked. Meanwhile, when CIJ printers go down, it will often require a service technician to perform the maintenance and most of the time comes at a cost.

Lower cost per print with bulk ink

The running cost of consumables is always a big factor when choosing the right coding printer for the production line. This is the main reason Hx Ultro TIJ bulk ink delivery system was introduced. It offers high technology on a user-friendly platform to allow ease of operation while lowering the print per mark.

Hx Ultro TIJ is the first reliable bulk-ink delivery system that enables the use of solvent ink. Traditionally, all bulk-ink systems that were developed for a TIJ technology require manual settings, making them prone to breakdown due to human error and as a result, are deemed unreliable. The special patent technology of Hx Ultro that automatically guides and removes the accumulated gases using a vacuum pump outside of the ink system, has brought a new chapter of bulk ink systems for TIJ technology. This is also one of the reasons that allow the Hx Ultro to bring down its investment and operational costs resulting in a more economical coding technology.

For further information about this topic, please get in touch with MapleJet experts at technical@maplejet.com.

Recent Comments