Continuous Inkjet (CIJ) printing, Thermal Inkjet (TIJ) printing, Thermal Transfer Overprinting (TTO), Laser, and Drop on Demand (DOD) are the different coding and marking technologies competing to gain a significant market share in the industry. While CIJ printers have been commonly used, they are increasingly being replaced with other technologies due to their over-complicated nature and higher maintenance costs. Technological advancements are reshaping the industry, driving efficiency, and enhancing productivity. Among these printing technologies, TIJ printing technology is poised to capture a significant market share in the coding and marking arena.

In this blog, let us investigate why TIJ is leading the charge into the future to keep your coding and marking operations cutting edge.

What is TIJ Printing?

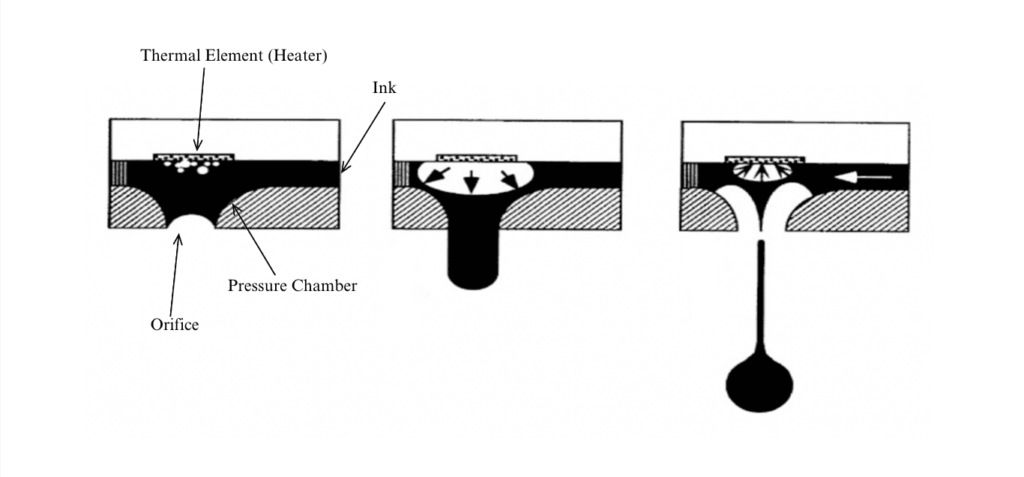

Thermal Inkjet (TIJ) printing uses heat to expel ink droplets onto a wide range of porous and non-porous substrates. A thermal element is heated within the printer, creating a bubble that forces a droplet of ink out of the nozzle. TIJ printing is renowned for its precision, reliability, and versatility. TIJ printers are compact, easy to maintain, and offer high-resolution printing, making them an ideal option for a wide range of applications.

Figure 1. Droplet formation of a thermal inkjet printer (Glynne-Jones, Peter & Coletti, et al, 2007)

Current Landscape of TIJ Printing

Market Conditions

The coding and marking industry is shifting towards advanced, sustainable, and cost-effective solutions. TIJ printing is at the forefront of this transition due to its ability to meet the increasing demand for high-quality and eco-friendly printing.

- Growing Demand for High-Quality Printing: Industries such as pharmaceuticals, food and beverage, and cosmetics are increasingly requiring high-resolution, precise printing to comply with regulatory standards and enhance product appeal.

- Economic Pressures: Companies are under constant pressure to reduce costs and improve operational efficiency. TIJ printing’s lower maintenance and operational costs are appealing in this economic climate.

- Sustainability Trends: With a growing emphasis on sustainable practices, businesses are seeking printing solutions that minimize waste, reduce health risks, and reduce environmental impact. TIJ’s eco-friendly inks and reduced energy consumption align well with these goals.

Customer Needs

Customer expectations are evolving, driven by regulatory requirements and the need for enhanced efficiency. TIJ printing addresses several key customer needs:

- Regulatory Compliance: Industries like pharmaceutical and food are requiring more precise, legible coding for compliance with stringent regulations. Especially, with the upcoming regulation of GS1 Sunrise 2027, which mandates the use of 2D barcodes on product packaging to improve supply chain efficiency and traceability. TIJ printers are well-suited to meet these new requirements, offering the precision and reliability needed for compliant 2D barcode printing.

- Brand Differentiation: High-quality printing helps brands stand out on the shelves. TIJ printing’s ability to produce sharp, detailed graphics and text enhances product aesthetics.

- Operational Efficiency: Businesses need reliable, low-maintenance printing solutions to minimize downtime. TIJ printers are known for their ease of use and minimal maintenance requirements.

Competitive Forces

The competitive landscape in the coding and marking industry is intense, with several key players vying for market share. TIJ printing has several competitive advantages:

- Innovation and Technological Advancement: TIJ technology is rapidly evolving, with continuous improvements in print speed, resolution, and ink formulations. This keeps TIJ at the cutting edge, outpacing older technologies like CIJ.

- Cost Advantages: TIJ printers offer lower total cost of ownership due to reduced maintenance and consumable costs. This makes them a more attractive option compared to CIJ printers.

- Flexibility and Adaptability: TIJ printers are versatile and can be integrated into various production environments with minimal modifications. This flexibility is a significant advantage for TIJ printers over other printing technologies.

Technological Advancements

TIJ printing technology is benefiting from several key advancements:

- IoT Integration: TIJ printers are increasingly being integrated with the Internet of Things (IoT), enabling real-time monitoring and predictive maintenance. This reduces downtime and improves operational efficiency.

- Enhanced Ink Formulations: Advances in ink formulations are expanding the range of substrates that TIJ printers can handle, including difficult-to-print materials like metals and plastics.

- Smart Manufacturing: TIJ printers are playing a crucial role in smart manufacturing environments, where connectivity and automation are key. Features like remote monitoring, field upgrades, and seamless integration with other devices are becoming standard, supporting Industry 4.0 initiatives.

Trends in TIJ Printing

Recent Technological Advancements

At MapleJet, we are already incorporating several of these advancements into our TIJ printers, such as the Hx Nitro. Here are some trends that will continue to shape the future of TIJ:

- Continued IoT Integration: Our Hx Nitro TIJ printer already includes IoT capabilities. Ongoing enhancements through MapleJet Cloud will further improve real-time monitoring, providing valuable data on performance, ink levels, and maintenance needs. Additional enhancements will further enhance predictive maintenance to reduce downtime and extend the life span of the printer and overall efficiency.

- Enhanced Capabilities: Future improvements will focus on expanding the versatility of TIJ printers, allowing them to handle an even broader range of substrates with higher speed and precision. Currently, MapleJet TIJ printers can print on almost all types of substrates.

- Smart Technology and Connectivity: MapleJet printers are equipped with smart technology features, including cloud connectivity and advanced data management, ensuring they remain at the forefront of printing technology.

Market Shifts

Increasing Adoption:

- Industry Adoption: More industries are adopting thermal inkjet printing for its reliability, cost benefits, and superior print quality. The trend is particularly notable in sectors requiring high precision and clean operations, such as pharmaceuticals and electronics.

- Consumer Preferences: As consumers demand higher-quality packaging and labelling, brands are turning to TIJ technology to meet these expectations. The ability to print high-resolution graphics and text enhances brand image and consumer appeal.

Regulatory Compliance:

- Stringent Standards: TIJ’s ability to produce high-quality, readable prints is crucial for compliance with stringent regulatory standards, further driving its adoption. For example, the pharmaceutical industry requires clear and accurate labelling to ensure patient safety and regulatory compliance.

- Traceability: Enhanced print quality and data integrity offered by TIJ are vital for traceability in supply chains, especially with the introduction of GS1 Sunrise 2027. This is particularly important in industries like pharmaceuticals and food and beverage, where traceability is essential for greater product information transparency, traceability, and authentication

Sustainability:

- Environmental Impact: Thermal Inkjet printers are known for their efficiency and environmental benefits. One of the key advantages of TIJ technology is its significantly lower consumption of Methyl Ethyl Ketone (MEK) solvents compared to Continuous Inkjet systems. TIJ printers, particularly the MapleJet Hx Ultro, generate less or even zero MEK solvent evaporation because the MEK in MapleJet printer’s ink, eUrex, is pre-mixed and it is a closed-loop system, unlike in CIJ printers where the returned ink is constantly monitored for viscosity, necessitating the addition of solvent to counteract fluid loss.

- Energy Efficiency: TIJ printers consume less energy, contributing to lower operational costs and a reduced carbon footprint. This makes TIJ an attractive option for companies looking to improve their sustainability credentials.

Why You Should Replace Your CIJ Printers with TIJ

Superior Print Quality:

- Resolution: TIJ printers like our MapleJet Hx Nitro offer resolutions up to 600 dpi, producing crisp and clear prints, without sacrificing speed. CIJ printers, on the other hand, typically provide lower resolution, around 70 – 80 dpi. The superior print quality offered by TIJ is essential for industries where readability and aesthetics are crucial, such as pharmaceuticals and cosmetics, whereas CIJs can result in less detailed and less legible prints.

- Precision: TIJ’s precision makes it ideal for intricate designs and small text. This precision ensures that barcodes, batch numbers, and expiration dates are clear and easy to read, which is vital for compliance and safety.

Figure 2. Print quality comparison between CIJ (orange package) versus TIJ (green package)

Technology:

- Cloud Connectivity: TIJ printers like the MapleJet Hx Nitro offer cloud connectivity, allowing for real-time data access, remote monitoring, and improved production management.

- Throw Distance: TIJ printers are now offering long-throw distance technology allowing printing even on recessed and curved surfaces. Additionally, more technological advancements are increasing the throw distances of TIJ printers, closing the gap between TIJ and CIJ printers.

- Smart Technology: TIJ printers like the ones offered by MapleJet incorporate smart features such as predictive maintenance, automated adjustments, and integration with other smart devices, enhancing overall efficiency and reducing downtime.

Cost-Effectiveness:

- Maintenance: TIJ printers require minimal maintenance compared to CIJ printers. CIJ need constant servicing to avoid nozzle blockages and ink build-up, causing increased downtime and maintenance costs. TIJ printers, like the MapleJet Hx Nitro with their cartridge-based systems, require little to no maintenance, resulting in lower operational costs.

- Consumables: TIJ uses easily replaceable cartridges, which are more straightforward and less expensive to manage than the complex fluid systems used in CIJ. This simplicity translates to significant savings on training and consumables, reducing the overall cost of ownership.

Eco-Friendliness:

- Waste: TIJ printers generate less ink waste compared to CIJ printers. CIJ printers need to be flushed out regularly to prevent clogging, which leads to wasted ink. TIJ’s cartridge system minimizes waste, making it a more environmentally friendly option.

- Energy Consumption: TIJ printers consume less energy than CIJ printers, reducing operational costs and adhering to sustainable practices. Lower energy consumption not only saves you money but also helps your organization contribute to environmental sustainability.

- Health Benefits: TIJ printers are a healthier option for the workers who operate in your production lines. CIJs typically use solvent-based inks that emit harmful volatile organic compounds (VOC), which could cause various health risks such as damage to the liver, kidneys, and central nervous system. CIJ printers must use inks with higher VOC content as it help with the adhesion of the dye onto non-porous materials that require fast drying times. Because the CIJ print head is essentially open to the atmosphere, some of this solvent will evaporate into the air. This may cause problems for people working in the warehouse and may even penetrate food packaging. This issue is not found with TIJ printers due to their cartridge-based system and closed-loop design.

Operational Efficiency:

- Setup and Downtime: TIJ printers like the MapleJet HxNitro are plug-and-play devices, reducing setup time and downtime. CIJ systems require extensive setup, training, and frequent maintenance checks, which can interrupt production and decrease efficiency. TIJ’s ease of use and minimal downtime enhance overall productivity.

- Versatility: TIJ printers are versatile enough to print on a wide range of substrates, including porous and non-porous surfaces, by simply switching out the ink cartridge, making it adaptable for various industries. This versatility is crucial for manufacturers who need to code on different materials, from paper and cardboard to plastics and metals.

Thermal inkjet printing is not just a trend; it represents the future of the coding and marking industry. With superior print quality, cost-effectiveness, eco-friendliness, and operational efficiency, TIJ is set to revolutionize the way industries approach printing. As technology advances and market demands evolve, TIJ stands ready to meet the challenges of tomorrow, solidifying its place as the preferred choice for modern printing needs.

At MapleJet, we are proud to be at the forefront of this technological shift, offering cutting-edge TIJ solutions that cater to the diverse needs of our clients. Embrace the future of printing with TIJ and experience unparalleled quality and efficiency.

References:

Glynne-Jones, Peter & Coletti, M. & Gabriel, Steven. Advanced Injectors for Chemical Rockets Inspired by Ink-jet Printing Technology. Retrieved from https://www.researchgate.net/figure/Thermal-inkjet-from-Le-Hue-1_fig2_237335482

Recent Comments