Pipe manufacturers operate in some of the harshest production environments. From dust and abrasion to outdoor storage and curved surfaces, pipe marking systems must deliver prints that remain readable long after production.

UV inkjet technology has emerged as a reliable solution for marking metal, PVC, and ductile pipes with durable, high-contrast codes that withstand real-world conditions.

This article explores the challenges of pipe marking, the advantages of UV inkjet printing, and how to choose the right printer configuration for different pipe applications.

Challenges in Pipe Marking Environments

Pipe production lines place unique demands on coding and marking systems. Unlike flat packaging surfaces, pipes introduce multiple physical and environmental challenges.

Abrasion, Dust, Moisture, and Outdoor Exposure

Pipes are often stored outdoors, stacked, transported, and handled repeatedly. Printed codes must resist abrasion, moisture, and exposure to sunlight without fading or peeling.

Curved Surfaces and Line Speed

Printing on cylindrical surfaces requires consistent print quality across varying diameters. At the same time, many pipe extrusion and forming lines operate at high speeds, leaving little margin for smearing or misalignment.

Need for Bold, Legible Marks on Ductile Pipes

Ductile and industrial pipes often require large, highly visible markings for identification, standards compliance, and traceability. Small or low-contrast prints are difficult to read once pipes leave the factory floor.

Why UV Inkjet Is Ideal for Pipe Manufacturing

UV inkjet printing addresses many of the limitations of conventional ink systems used in pipe marking.

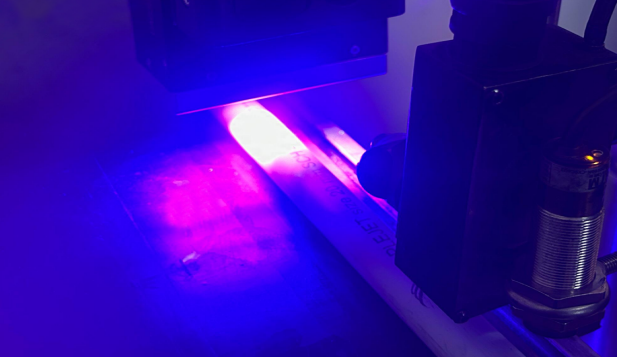

Instant Curing and Smear Resistance

UV inks cure immediately when exposed to UV light. This eliminates drying time and prevents smudging, even at high production speeds or when pipes come into contact with rollers and guides.

Excellent Adhesion on Metal and Plastic

UV inks bond effectively to both porous and non-porous surfaces. This makes them well suited for metal, PVC, and coated pipe materials where traditional inks may struggle to adhere.

Long-Term Readability During Storage and Transport

Once cured, UV prints are highly resistant to abrasion, chemicals, and environmental exposure. This ensures that critical pipe information remains legible throughout storage, shipping, and installation.

White and Black Inks for Pipe Applications

Contrast is critical in pipe marking, especially in industrial environments.

High-Contrast Printing on Dark and Light Substrates

White UV ink provides excellent visibility on dark metal or PVC pipes, while black ink delivers sharp, readable marks on light-colored substrates. This flexibility allows manufacturers to maintain consistent coding standards across different pipe types.

Suitable for Metal, PVC, and Ductile Pipes

Both white and black UV inks are engineered to perform on a wide range of pipe materials, ensuring reliable adhesion and durability without frequent ink changes.

Choosing the Right UV Printer for Pipe Marking

Hx Evo – Medium Character Industrial Pipe Marking

Hx Evo is well suited for pipe applications that require clear, medium-sized character printing

with flexible mounting options. It is ideal for manufacturers looking for a compact UV solution

that can adapt to varying pipe diameters and production layouts.

Best suited for:

- Continuous extrusion lines

- Medium-sized identification codes

- Pipe, cable, and industrial manufacturing

(Reference source: Hx Evo Catalogue)

Hx Megalo – Large Character and Stitched Pipe Marking

For applications requiring oversized text, logos, or multi-line information, Hx Megalo offers large-format UV printing capabilities.

With up to 70mm print height and stitched message capability, it enables bold, highly visible markings across wide pipe surfaces, making it especially suitable for ductile and heavy industrial pipes.

Best suited for:

- Large diameter ductile pipes

- Branding on pipe bodies

- High-visibility compliance markings

(Reference source: Hx Megalo Catalogue)

Commercial Considerations for Pipe Manufacturers

When selecting a pipe marking system, manufacturers should evaluate:

- Total cost of ownership (ink consumption, maintenance, downtime)

- Ease of integration with extrusion lines

- Long-term durability of codes in outdoor environments

- Scalability across multiple pipe sizes

UV inkjet systems reduce rework caused by unreadable codes and minimize production interruptions due to drying delays.

For operations managers, this translates to higher uptime.

For business owners, it means lower long-term operational risk.

Conclusion

UV inkjet technology provides a robust, long-term solution for pipe marking across metal, PVC, and ductile applications.

By combining instant curing, strong adhesion, and high-contrast inks, UV printers help pipe manufacturers achieve durable, legible codes that survive demanding environments.

Choosing between systems like Hx Evo and Hx Megalo allows manufacturers to match print size, speed, and durability requirements without compromising production efficiency.

Recent Comments