GS1 barcodes are at the heart of supply chains, ensuring that products can be identified and tracked anywhere in the world. But when it comes to printing these barcodes, choosing the right printer is key. Here’s everything you need to know about GS1 and what to look for in a barcode printer.

What is GS1?

GS1 is a global organization that develops and maintains standards for business communication, most notably in the form of barcodes. These barcodes contain essential data such as product identification, batch numbers, and expiration dates, ensuring that the information can be scanned and understood anywhere in the world.

GS1 barcodes come in several formats, including the familiar EAN/UPC barcodes, GS1 DataBar, and 2D barcodes like GS1 DataMatrix and GS1 QR codes. Each type serves different purposes, from retail checkouts to high-level logistics tracking. However, all GS1 barcodes must meet strict standards to ensure they are scannable across various platforms and devices.

Choosing a printer that can consistently meet these standards is crucial, especially for industries such as food, pharmaceuticals, and retail, where accurate tracking and compliance with global regulations are vital.

Steps to Choose the Right GS1 Barcode Printer

Once you understand the role of GS1 in ensuring global standards, the next step is to choose a barcode printer that aligns with these needs. Here are the key features to look for:

1. GS1 Compliance

The first and most important requirement for any barcode printer is GS1 compliance. This means the printer must be able to produce barcodes in the correct size, with the right encoding, and ensure that the printed codes are readable by any scanner that adheres to GS1 standards.

A GS1-compliant printer ensures that your products move through the supply chain smoothly, without the risk of rejected shipments or delays due to unreadable barcodes.

2. Print Quality and Resolution

Quality matters when it comes to barcode printing. GS1 barcodes need to be clear and readable from the moment they are printed until they reach their final destination. A printer with high resolution (at least 300 DPI) is necessary to produce sharp, crisp barcodes, especially when printing on rough or uneven surfaces like corrugated boxes or shrink-wrapped pallets.

Good print quality reduces scanning errors, saving time and preventing costly delays in the supply chain.

3. Versatility in Barcode Formats

A GS1 barcode printer should be able to handle multiple formats of barcodes. Depending on your industry, you may need to print anything from simple EAN/UPC barcodes to more complex GS1 2D barcodes like DataMatrix. Having a printer that can support these different formats gives you flexibility and ensures that you can meet diverse labelling needs as your business grows.

4. Integration Capabilities

Supply chains often require printers that can seamlessly integrate with existing systems, whether it’s your ERP, warehouse management system, or production line software. Printers that offer flexible connectivity options—such as Ethernet, USB, or wireless—will fit more easily into your current setup without requiring costly modifications.

Integration with third-party devices, such as PLCs (Programmable Logic Controllers), also adds value by providing more control over the printing process and reducing manual input errors.

5. Speed and Durability

For businesses with high-volume production or fast-moving supply chains, speed is essential. A printer that can handle high throughput without compromising on quality is a must. You’ll also want a printer that is built for durability, capable of withstanding the rigours of an industrial environment, including exposure to dust, heat, and continuous operation.

Reliable printers reduce downtime, ensuring that your production line continues to run smoothly.

How MapleJet Printers Meet GS1 Barcode Requirements

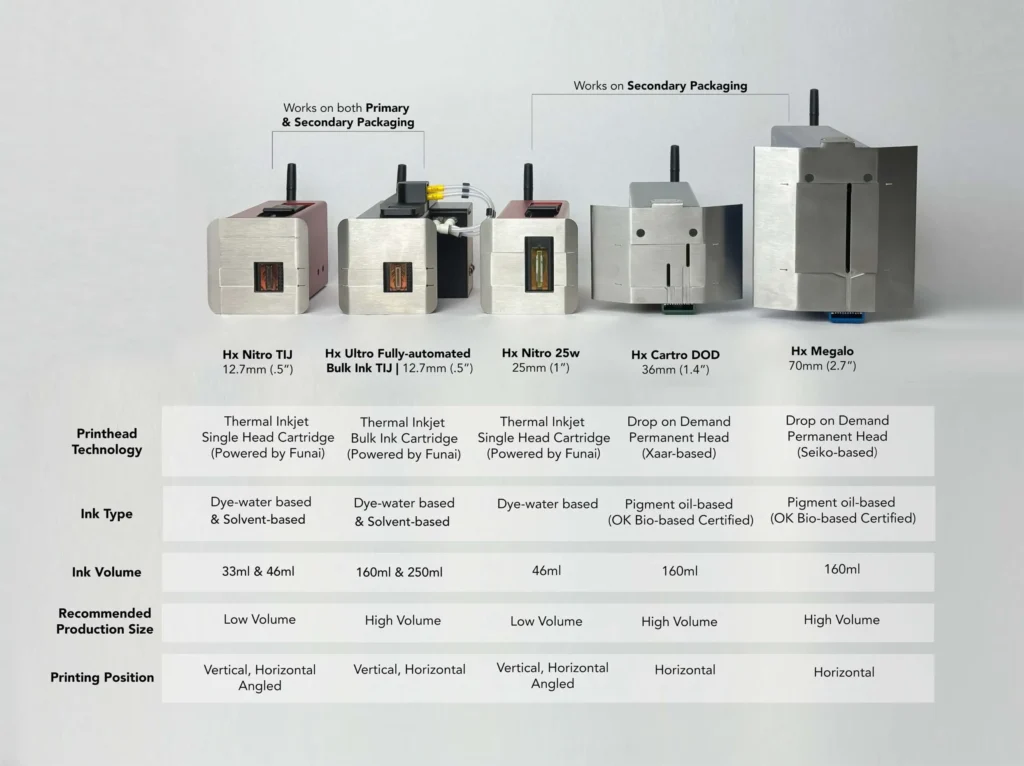

MapleJet’s range of industrial printers is designed with all the above features in mind, making them a strong choice for GS1 barcode printing:

- GS1 Compliance: All MapleJet printers are fully GS1-compliant. Ensuring that your barcodes meet international standards, whether you’re printing EAN/UPC codes or GS1 2D barcodes.

- High Print Quality: MapleJet printers deliver superior print quality with high-resolution output of up to 600 DPI. Making sure that your barcodes are scannable across all surfaces, from packaging to pallets.

- Versatility in Formats: With support for multiple barcode formats, MapleJet printers allow you to meet a wide range of industry requirements, from retail packaging to complex logistics tracking.

- Seamless Integration: Designed for flexibility, MapleJet printers integrate easily with ERP and external data systems, making them adaptable to your specific production line needs. They also support third-party devices for better process control.

- High-Speed Performance and Durability: Built for industrial environments, MapleJet printers offer high-speed printing without sacrificing quality, making them ideal for fast-paced operations. Their durable construction ensures they can withstand the toughest conditions with minimal maintenance.

When choosing a GS1 barcode printer, it’s important to prioritize GS1 compliance, print quality, versatility, integration capabilities, and speed. Ensuring these features will help your business stay compliant and efficient throughout the supply chain. MapleJet printers, offer a reliable solution for businesses looking to meet GS1 standards while maintaining high performance.

If you’re looking for a GS1 barcode printer that checks all these boxes, consider exploring MapleJet’s range of solutions. Contact us for a demo or to learn how our printers can enhance your barcode printing operations.

Recent Comments