Flexible packaging may seem like an abstract category at first glance. But the term corresponds to a small assortment of certain familiar materials. All you have to do is imagine some everyday food found in supermarkets to understand what “flexible packaging” means to us. Almond milk cartons, snack food packs, cheese film pouches, cookie packets each of these containers is a substrate made of aluminum foil, paper, coated paper, plastic, film, or a combination of both porous and non-porous materials. This will exemplify the idea of what flexible packaging is actually.

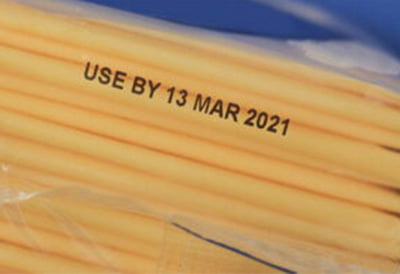

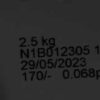

Of course, because this category comprises different materials, people working in the packaging industry can be confused about the best way to print on these products, as they are all different. This is especially important for food business operators as edible products need to carry date information/codes to ensure traceability in recalls and notify consumers when products are no longer safe.

Essential Factors to consider while printing date codes on pouch

Before choosing a printer or ink, you need to consider the unique characteristics of your production line. After all, just as there are similar differences in the flexible packaging categories, you can use these materials in very different ways with the same packaging operation.

Take a look at the setup and consider the following:

The code you need to print?

While printing on any flexible packaging such as pouch bags, the most significant thing is to consider the code required for your product. Specific codes (expiration date, lot code, package date, etc.) convey information without scanning. Therefore, other codes (barcodes, QR codes, etc.) require scanning capabilities. To make sure that you can scan these letters without error. It would be best if you have a printer that can reliably encode this information at high resolution.

Generally, thermal inkjet (TIJ) printers are better for scannable barcodes because they print at a more excellent resolution.

Substrate wrinkling:

Printing on flexible film can be fragile, so wrinkles can occur if the tension is not adjusted correctly through the printing process. The material should be kept taut without the web breaking, but it is still flexible enough to flow through the printer’s rollers.

Dirt and pollutants:

In industrial environments such as printing rooms, operating machines promote static electricity, attracting floating dust, small ink particles, and other contaminants that can accumulate on printed elements and substrates. These contaminants can compromise the quality of the entire printing process. Therefore, keep the environment as clean as possible.

Flaking ink:

Not every ink works on all flexible substrates, so make sure to know what flexible pouch materials you are using and couple it with a fast-drying ink to print on your pouch. Inks that do not dry properly will not adhere and may come off the film’s surface or when the material is bent and accidentally rubbed.

What kind of ink do you need?

Flexible pouch packaging is a vast material category, so it is imperative to use the best ink for your product. In other words, you should consult an expert to make sure you are using the correct ink, you can use a customized ink, or to confirm that the printer can use the link of your choice also. You can speak to our expert and send your sample here.

The right information

With the right products and the proper guidance, printing date codes on pouch packaging are easy. Most printing problems are caused by using the wrong combination of printer and ink. You can easily avoid this by consulting a coding and marking expert.

Here, Maplejet’s team of experts has been providing printers for over 14 years. We have witnessed the evolution of production line technology and understand the challenges inherent in modern manufacturing. When you work with us, we can help you find a printer and ink combination that perfectly suits your needs and the specifications of your production line.

For more information and questions, call 905-482-3106 today at MapleJet; we are more than ready to help you.

Recent Comments