Printing on Ceramic Packaging with Maplejet ProDigit Industrial Inkjet Printer

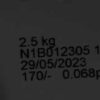

Printing the right information into ceramic packaging is important. Ceramic tiles undergo sorting during production to determine the size, grade, and aesthetic category of the tile before it goes for packaging.

While other industrial inkjet printers deliver basic printing requirements for printing on ceramic packaging, Maplejet ProDigit provides comprehensive solutions. From printing simple production date, barcodes, batch number to encoding critical data that should correspond to printing the correct information sent through from the Control Center.

To do this, Maplejet designed a complete solution using a BCD Interface Module. This module serves as a translator unit between the Control Center and Maplejet ProDigit Printer to select the related message that comes from the packaging station. Interestingly, BCD will send a message selecting the “Auto Pilot” command to the Maplejet PD controller thru the RS232 protocol that is based on BCD code. Once this is received via STROBE signal, the “Auto Pilot” ability activates from the Maplejet PD controller. This project was successfully delivered through Honaz FZCo, the company responsible for Maplejet’s global sales and operation.

MapleJet collaborates with Ink partners to provide Sky Blue Ink for a Pipe Manufacturing Company

In order to achieve the sky blue ink requirement of a pipe manufacturing company, Maplejet collaborated with its ink partners to come up with a solution. Developing new inks for certain applications, substrates, and environment is an extremely challenging task; thus, achieving the desired result takes a lot of time and trials. The new ink has to undergo a lot of testing to determine its adhesion to substrates and drying time.

With this success, Maplejet aims to continue working on projects with a specific ink requirement to better cater its customers’ needs.

MapleJet recommends fine-tuning the Print Module to maintain superior print quality

Fine-tuning the print module allows printer users to put the print module as close as possible to the product. When this ideal distance is achieved, it will maintain the superior print quality of the printer on the material.

In cases when the print module experiences nozzle clog or when print quality on the substrate is bad, it is necessary to fine-tune the print module.

To see visual instruction on how to fine-tune ProDigit 18 square-type Print Module, please click this link ‘Fine Tuning Print Module’.

Range of

Maplejet Corrugated Box Printer

1. Single color 18mm permanent head one-side printing

2. Single color 18mm with two permanent heads for two-sided printing

3. Single color 70mm one-side printing

4. Single color 70mm two-side printing

5. Single color 140mm one-side printing

6. Single color 140mm two-side printing

7. Bi-color 18mm one-side printing

8. Bi-color 18mm two-side printing

Upgrading from TIJ to Maplejet range of carton printers Reduces Production Costs and helps to Save the Environment.

Recent Comments